Jan . 15, 2025 05:45

Back to list

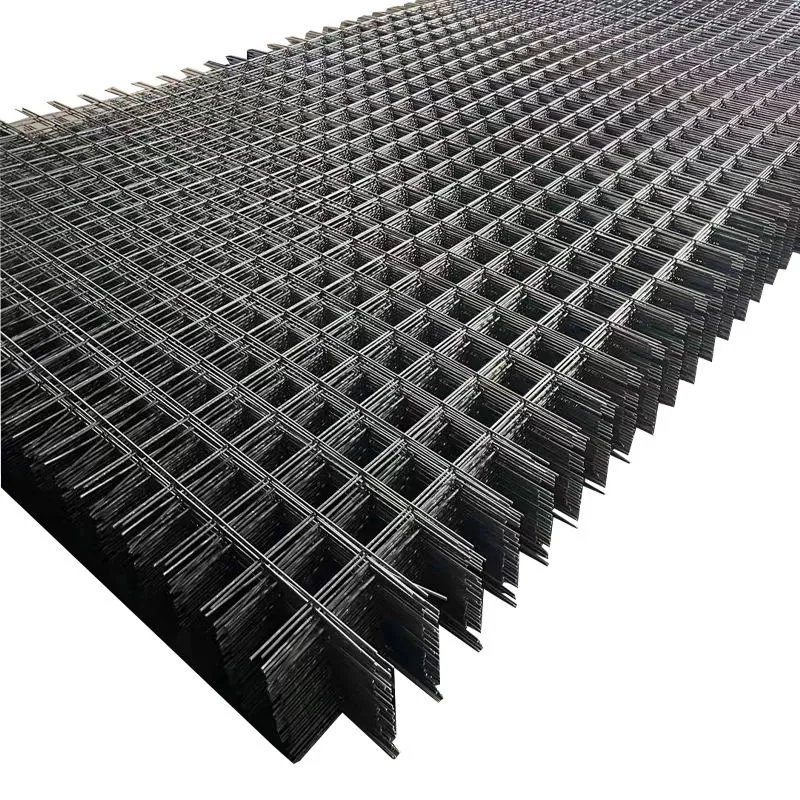

Hot Sale Platform Grating Heavy Duty G325/30/100 Steel Grating

Catwalk grating walkways are crucial components in industrial and commercial settings, providing safe and durable pathways for maintenance and operations. Their design and material composition offer a myriad of benefits, setting them apart as indispensable fixtures in sectors that prioritize safety and efficiency.

Maintenance considerations are a critical aspect of the lifecycle of catwalk grating walkways. Designed for longevity, they require minimal upkeep, reducing downtime and maintenance costs over time. Regular inspections ensure that the walkway remains in optimal condition, while periodic cleaning and minor repairs can extend its life significantly. In environments with high exposure to corrosive elements or heavy foot traffic, treating the grating with protective coatings can further enhance durability. Trust in the reliability of catwalk grating walkways is bolstered by adherence to rigorous industry standards and engineering benchmarks. These walkways are often crafted in compliance with ASME, OSHA, and other relevant regulatory bodies, which provide frameworks ensuring pedestrian safety and load-bearing capabilities. Partnering with experienced manufacturers who adhere to these standards guarantees that their products are both authoritative and trustworthy solutions for contemporary infrastructural challenges. In conclusion, catwalk grating walkways serve as a vital asset within any facility needing durable, safe, and efficient pedestrian access. Their inherent strength, adaptability, and low-maintenance make them an expert choice for enhancing operational safety and efficiency. As industrial demands continue to evolve, these walkways will undoubtedly remain a hallmark of engineering excellence, trusted by professionals across diverse sectors.

Maintenance considerations are a critical aspect of the lifecycle of catwalk grating walkways. Designed for longevity, they require minimal upkeep, reducing downtime and maintenance costs over time. Regular inspections ensure that the walkway remains in optimal condition, while periodic cleaning and minor repairs can extend its life significantly. In environments with high exposure to corrosive elements or heavy foot traffic, treating the grating with protective coatings can further enhance durability. Trust in the reliability of catwalk grating walkways is bolstered by adherence to rigorous industry standards and engineering benchmarks. These walkways are often crafted in compliance with ASME, OSHA, and other relevant regulatory bodies, which provide frameworks ensuring pedestrian safety and load-bearing capabilities. Partnering with experienced manufacturers who adhere to these standards guarantees that their products are both authoritative and trustworthy solutions for contemporary infrastructural challenges. In conclusion, catwalk grating walkways serve as a vital asset within any facility needing durable, safe, and efficient pedestrian access. Their inherent strength, adaptability, and low-maintenance make them an expert choice for enhancing operational safety and efficiency. As industrial demands continue to evolve, these walkways will undoubtedly remain a hallmark of engineering excellence, trusted by professionals across diverse sectors.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP