Expanded metal mesh is an invaluable material across various industries, offering a blend of strength, versatility, and cost-effectiveness. Not all expanded metal meshes are created equal; the types vary significantly based on their intended applications, materials, and manufacturing processes. Understanding these differences is crucial for professionals seeking the best solutions for their specific needs.

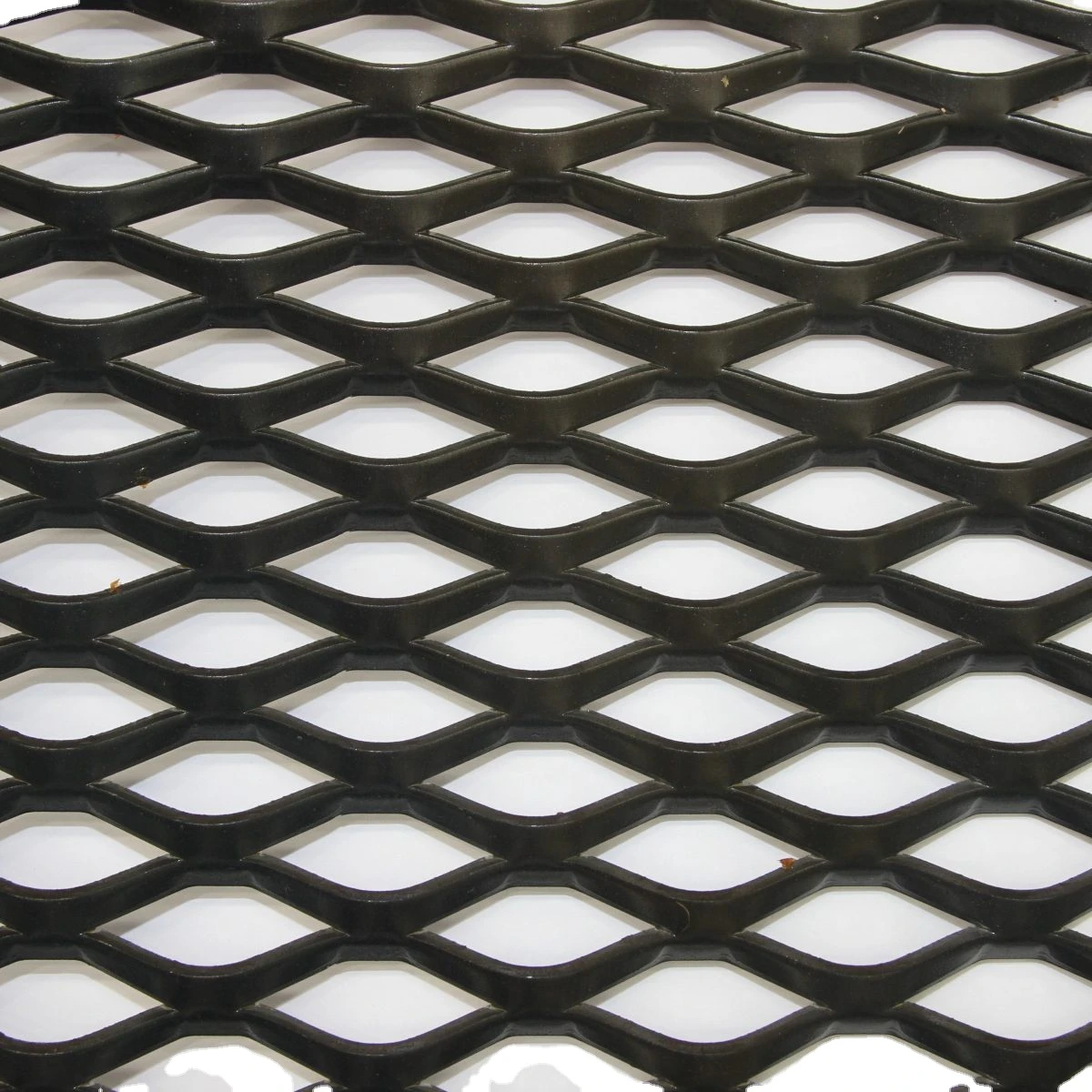

Expanded metal mesh begins as a sheet of metal—often aluminum, stainless steel, or carbon steel—that is simultaneously slit and stretched, forming a mesh with diamond-shaped openings. This process does not involve any welding or pressing, making it highly efficient and waste-free. The unique properties of expanded metal mesh stem from this production method, where the metal retains its strength and inherent rigidity, offering distinct advantages over alternatives like wire mesh or perforated sheets.

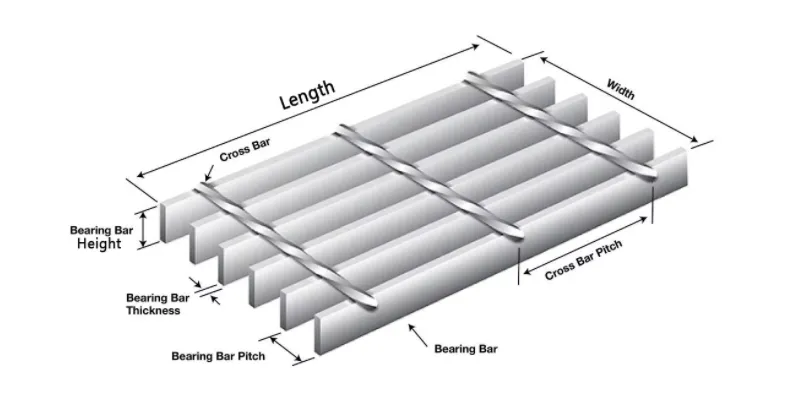

Expanded metal meshes can be classified into different types, primarily distinguished by their patterns, material, and specific end-use applications. Standard expanded metal, often referred to as raised mesh, features strands and bonds positioned at an angle to the plane of the sheet. This configuration enhances strength while allowing for excellent airflow and light diffusion. Its non-flat nature also provides superior traction, making it ideal for walkways and stair treads.

Flattened expanded metal is the result of passing standard expanded metal through a cold rolling press. This process reduces the thickness slightly and flattens the strands and bonds—retaining the material's strength while offering a smooth and even surface profile. This type is suitable for applications requiring a sleek appearance or when used as a grill or fencing material where aesthetics are important.

Micro expanded metal mesh is a more specialized variation featuring much smaller openings. Made with precision, this type serves specific scientific and industrial purposes, such as filters or components in advanced technology applications like aerospace. The precision and uniformity in micro expanded metal mesh are critical in its performance, underlining the importance of manufacturer expertise and quality control.

types of expanded metal mesh

Decorative expanded metal meshes combine aesthetics with functionality, offering intricate patterns to architects and designers. Available in various metals and finishes, they hold uge potential in architectural facades, interior design, and art installations. Its ability to reflect light and offer varying degrees of transparency and shadow play adds a dynamic visual element to structures and spaces.

Choosing the correct type of expanded metal mesh involves considering factors such as load-bearing capacity, environmental exposure, and application-specific requirements. Moreover, professionals working with this material must navigate a complex web of industry standards and specifications to ensure compliance and optimal performance.

A thorough understanding of metal types and coatings is also pivotal for ensuring durability and maintenance. For instance, stainless steel provides enhanced corrosion resistance, making it suitable for harsh environments, while aluminum offers both corrosion resistance and a lightweight alternative for applications where weight is a critical factor.

Adopting the right expanded metal mesh type is not just about meeting technical requirements but also about longevity and cost-effectiveness. As such, experts often consult with manufacturers who demonstrate authoritative knowledge and practical experience. This consultative approach ensures that projects not only achieve immediate objectives but also benefit from sustainable and reliable outcomes over time.

Ultimately, the diversity in expanded metal mesh types underscores the necessity for expertise and trustworthiness in product selection. Industries ranging from construction to pharmaceuticals depend on this versatile material, making expert insights indispensable in leveraging its full potential. Mastery in selecting and utilizing expanded metal mesh not only maximizes functional benefits but also ensures safety, efficiency, and profitability for any endeavor.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.