In the world of drainage systems, steel trench drain grates are essential components that ensure effective water management and prevent flooding. These grates are designed to cover trench drains, allowing water to flow through while keeping debris and larger objects out of the drainage system. One of the most significant advantages of using galvanized trench drain grate products is their remarkable resistance to corrosion, which is particularly important in environments exposed to moisture and various chemicals. This corrosion resistance is primarily due to the zinc coating applied to the steel, which forms a protective barrier against environmental factors.

The process of galvanization involves coating steel with a layer of zinc, creating a durable and robust surface that can withstand harsh conditions. This zinc layer plays a crucial role in protecting the underlying steel from rust and degradation. When the galvanized trench drain grate is exposed to moisture, the zinc reacts with oxygen and carbon dioxide in the air, forming zinc carbonate. This compound adheres to the surface and further protects the steel beneath it. As a result, galvanized steel trench drain grates can last significantly longer than their non-galvanized counterparts, making them a wise investment for both residential and commercial applications.

Moreover, the versatility of trench drain cover steel makes it suitable for a variety of settings, including industrial sites, parking lots, and residential driveways. The strength and durability of these grates ensure they can handle heavy loads and traffic without compromising their integrity. For businesses and homeowners looking to enhance their drainage systems, investing in high-quality galvanized trench drain grates is a decision that pays off in terms of longevity and performance.

The Science Behind Galvanization and Corrosion Resistance

The process of galvanization not only provides a protective layer but also alters the chemistry of the steel itself. When galvanized trench drain grate products are manufactured, the steel is cleaned and then immersed in molten zinc. This process creates a metallurgical bond between the zinc and the steel, resulting in a coating that is both tough and adherent. The corrosion resistance of galvanized steel is a direct result of this unique interaction, which allows the zinc layer to act as a sacrificial anode.

In simpler terms, when the galvanized surface is scratched or damaged, the exposed steel is still protected by the surrounding zinc. The zinc will corrode preferentially, sacrificing itself to protect the underlying steel from rust. This phenomenon is known as cathodic protection, and it is a critical feature that enhances the lifespan of steel trench drain grates. While the zinc layer may wear away over time, it does so at a much slower rate than unprotected steel would corrode.

Additionally, the environmental conditions play a significant role in the longevity of galvanized products. In areas with high humidity or where chemical exposure is common, such as in industrial settings, the protective properties of galvanized steel become even more vital. The stainless steel drainage grates offer another layer of protection, as they are inherently resistant to corrosion due to their chromium content. However, for applications where cost-effectiveness is essential, galvanized trench drain grates provide an excellent balance between performance and price.

Advantages of Stainless Steel Drainage Grates

While galvanized trench drain grate products are known for their corrosion resistance, stainless steel drainage grates offer additional benefits that make them suitable for specific applications. Stainless steel is composed of iron, carbon, and a minimum of 10.5% chromium, which gives it its corrosion-resistant properties. Unlike galvanized steel, which relies on a zinc coating, stainless steel forms a passive layer of chromium oxide that protects the metal from rusting. This makes stainless steel grates particularly useful in environments that are highly corrosive, such as coastal areas or locations where chemicals are frequently used.

The durability of stainless steel drainage grates is another advantage. They can withstand extreme temperatures and heavy loads, making them ideal for high-traffic areas. Additionally, the aesthetic appeal of stainless steel adds a modern touch to any drainage system, making it a popular choice for architectural applications. While the initial cost of stainless steel grates may be higher than that of galvanized options, their longevity and maintenance-free nature often justify the investment.

Moreover, businesses looking to enhance their drainage systems can benefit from the versatility of both galvanized and stainless steel options. Depending on the specific requirements of the project, choosing the right type of grate can significantly impact the overall effectiveness of the drainage solution. By offering a variety of products, including steel trench drain grates and trench drain cover steel, wholesalers can cater to diverse customer needs and preferences.

Choosing the Right Grate for Your Needs

When selecting a trench drain grate, it is essential to consider several factors, including the specific application, environmental conditions, and budget. Galvanized trench drain grates are an excellent choice for general drainage needs, especially in residential and light commercial settings. Their cost-effectiveness and corrosion resistance make them a popular option among homeowners and contractors alike. On the other hand, for more demanding environments, such as industrial sites or areas exposed to harsh chemicals, investing in stainless steel drainage grates may be more beneficial.

Understanding the differences between various types of grates can help ensure that you make an informed decision. For instance, trench drain cover steel products are designed to handle heavy loads and provide reliable performance under pressure. They are suitable for areas where vehicles frequently pass, ensuring that the drainage system remains functional and efficient. Additionally, the aesthetic considerations of the project should not be overlooked. The choice between galvanized and stainless steel can also depend on the desired appearance and finish of the installation.

Ultimately, the goal is to choose a drainage solution that meets both functional and aesthetic needs while providing long-lasting performance. By investing in high-quality products, customers can ensure that their drainage systems operate effectively for years to come. Wholesalers who offer a range of options, including steel trench drain grates, galvanized trench drain grate, and stainless steel drainage grates, are well-positioned to meet the diverse needs of their clientele.

FAQs: Understanding Galvanized Trench Cover Steel Grating

What are galvanized trench drain grates?

Galvanized trench drain grates are steel grates coated with a layer of zinc to protect against corrosion, making them ideal for various drainage applications.

How does the zinc layer protect steel from corrosion?

The zinc layer acts as a sacrificial anode, corroding preferentially to the underlying steel, thus protecting it from rust and degradation.

What is the difference between galvanized and stainless steel drainage grates?

Galvanized grates rely on a zinc coating for protection, while stainless steel has a chromium layer that provides corrosion resistance, making it suitable for harsher environments.

Can galvanized trench drain grates be used in industrial settings?

Yes, galvanized trench drain grates are suitable for industrial settings, but for highly corrosive environments, stainless steel drainage grates may be a better choice.

How do I choose the right grate for my drainage system?

Consider factors such as the specific application, environmental conditions, load requirements, and budget to make an informed decision on the right grate.

Invest in Quality Drainage Solutions Today

To ensure effective drainage and long-lasting performance, invest in our high-quality steel trench drain grates, galvanized trench drain grate, and stainless steel drainage grates. Visit our website to explore our range of products and place your order today. Don’t compromise on quality—choose the best for your drainage needs!

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

ਖ਼ਬਰਾਂJul.10,2025

-

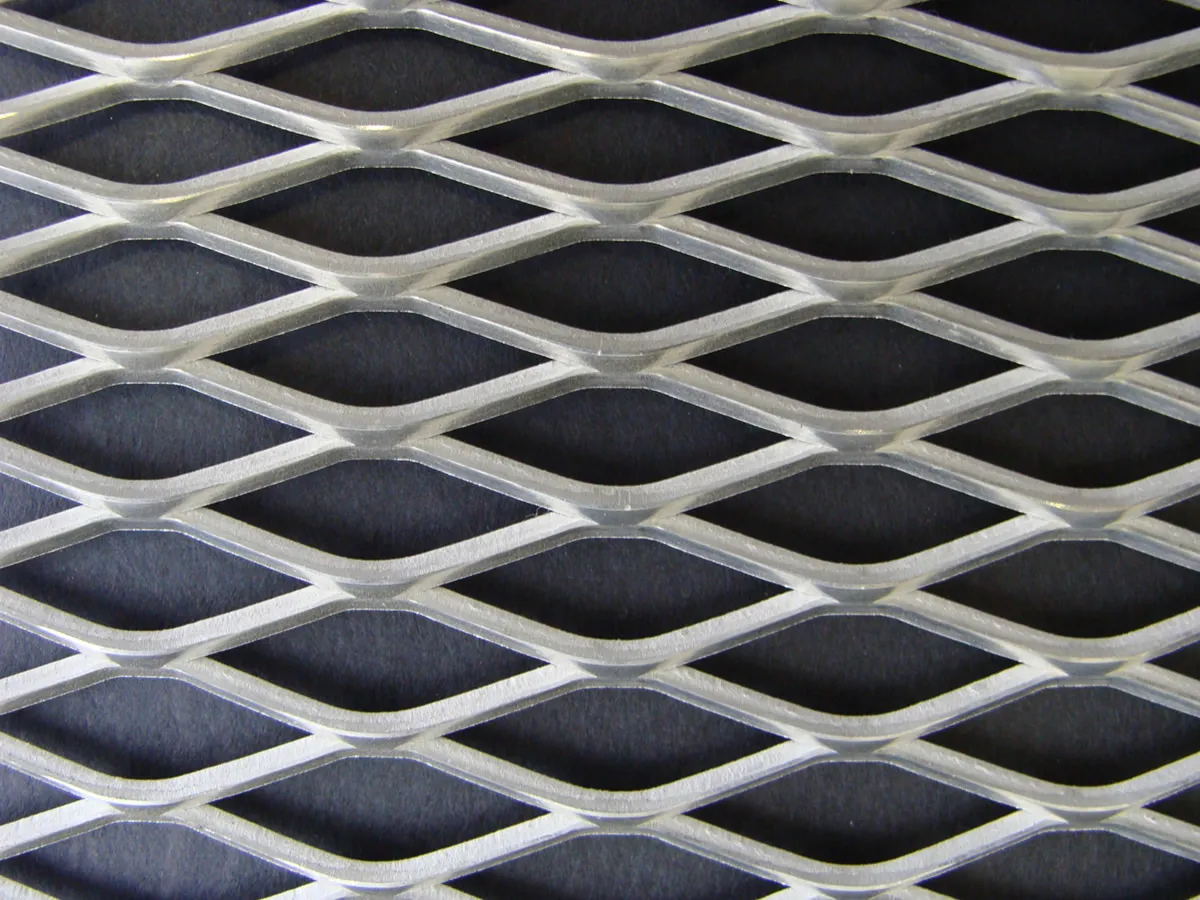

The Versatility and Strength of Stainless Expanded Metal Mesh

ਖ਼ਬਰਾਂJul.10,2025

-

Load Calculations in Steel Grating Platforms

ਖ਼ਬਰਾਂJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

ਖ਼ਬਰਾਂJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

ਖ਼ਬਰਾਂJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

ਖ਼ਬਰਾਂJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.