The Versatility and Benefits of Stainless Steel Perforated Metal

Stainless steel perforated metal has emerged as a vital material in various industries due to its unique combination of durability, aesthetic appeal, and functionality. This versatile product features a series of holes punched through metal sheets, allowing for improved airflow, light penetration, and aesthetic patterns, making it an ideal choice for numerous applications.

One of the primary advantages of stainless steel perforated metal is its incredible strength and resistance to corrosion. Stainless steel, an alloy composed mainly of iron, chromium, and nickel, offers excellent durability, making it suitable for both indoor and outdoor use. It can withstand harsh environmental conditions, further extending its lifespan compared to ordinary steel. This corrosion resistance makes stainless steel perforated metal a preferred option for industries where exposure to moisture or chemicals is common, such as food processing, pharmaceuticals, and architectural applications.

Another notable benefit of using perforated stainless steel is its ability to facilitate airflow and light transmission. The holes in the material can be customized in size, shape, and spacing, allowing for tailored applications in ventilation systems or for decorative purposes. For example, in buildings, perforated metal can be used as a facade or sunshade, allowing natural light to filter through while minimizing direct sunlight and reducing heat gain. This helps to improve energy efficiency, contributing to sustainable building practices.

stainless steel perforated metal

Aesthetically, stainless steel perforated metal provides a modern and industrial look that appeals to contemporary architectural designs

. Its clean lines and minimalist appearance can enhance a space’s visual appeal, making it a popular choice for everything from interior design to exterior cladding. Additionally, the ability to create custom patterns and designs means that this material can be tailored to match any design theme, offering infinite possibilities for creativity.In the realm of industrial applications, stainless steel perforated metal is widely used in filtration and separation processes. Its unique hole patterns allow for the separation of solids from liquids, making it ideal for various filtration systems across different industries. For instance, it is commonly used in wastewater treatment plants, chemical processing, and food and beverage production, where precision and reliability are paramount.

The manufacturing process of stainless steel perforated metal also allows for high levels of customization. Clients can choose from a range of thicknesses, hole sizes, and patterns to suit their specific needs. This customization ensures that the material not only meets functional requirements but also integrates seamlessly within the overall design of any project.

In conclusion, stainless steel perforated metal stands out as a highly versatile and valuable material across multiple industries. Its strength, corrosion resistance, aesthetic appeal, and functional benefits make it an excellent choice for both commercial and residential applications. As manufacturers continue to innovate with this material, the potential applications of stainless steel perforated metal will only expand, solidifying its status as a pivotal element in modern design and engineering. Whether used for practical purposes in industrial settings or as a stylish feature in architectural projects, stainless steel perforated metal undoubtedly exemplifies the perfect blend of form and function.

-

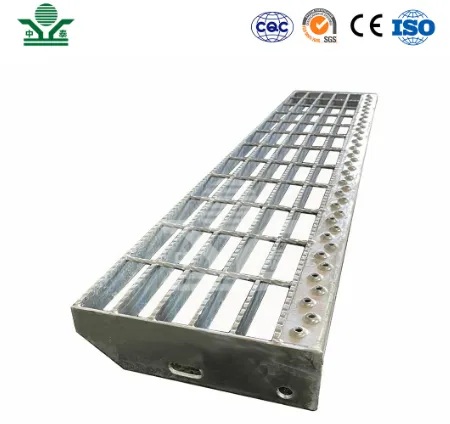

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.