ਫਰ. . 12, 2025 13:51

Back to list

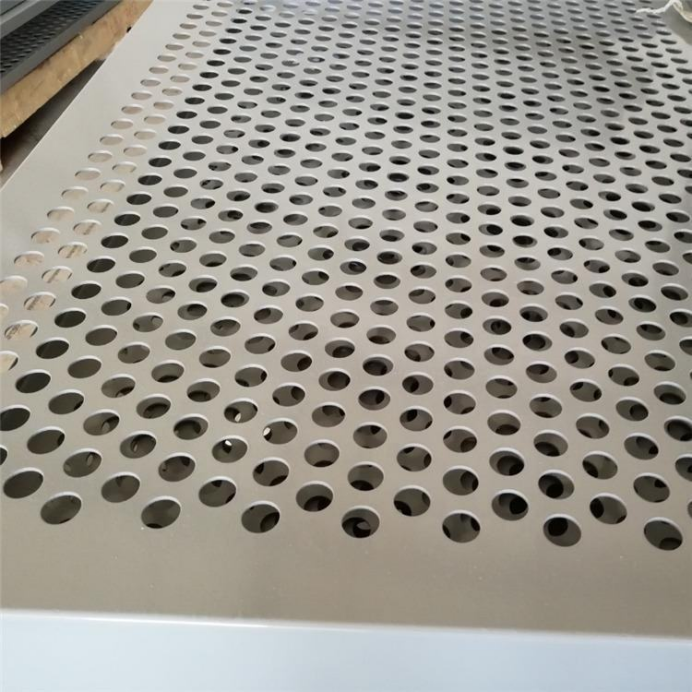

Punching Hole Wire Mesh China Suppliers Perforated Sheet Metal

Perforated sheet metal in a 4' x 8' size is a versatile and highly desirable product across numerous industries due to its unique combination of material strength, durability, and aesthetic appeal. Understanding the intricacies of this product and leveraging its benefits can significantly enhance its application effectiveness in manufacturing and design projects. This article delves into the expert considerations one must make when dealing with perforated sheet metal, emphasizing practical experiences and authoritative insights into its use.

Authoritative voices in the industry often emphasize the role of perforated sheet metal in sustainable design. Its use can contribute to energy savings through improved airflow and natural light management, supporting sustainable building certifications. Additionally, the recyclability of metals furthers its appeal in environmentally-conscious projects. In areas like acoustics, expertise in deploying perforated sheet metal can solve complex noise control challenges. Perforated panels can be used in conjunction with acoustic backing to manage sound levels effectively in auditoriums, factories, or office spaces, providing a dual function of aesthetic enhancement and noise control. Finally, concerns about maintenance and longevity are common among professionals who are selecting perforated sheet metal. Experience shows that regular maintenance, such as cleaning with appropriate solutions and inspection for wear and tear, extends the life of these materials. Protective coatings can also be applied to certain metals to enhance their durability against environmental stressors, ensuring lasting performance. In conclusion, the optimal use of 4' x 8' perforated sheet metal in products requires a careful balance of material properties, design considerations, and practical application insights. By combining deep industry expertise, real-world experience, and authoritative supplier partnerships, businesses and designers can harness the full potential of this versatile material, ensuring credibility and success in their projects.

Authoritative voices in the industry often emphasize the role of perforated sheet metal in sustainable design. Its use can contribute to energy savings through improved airflow and natural light management, supporting sustainable building certifications. Additionally, the recyclability of metals furthers its appeal in environmentally-conscious projects. In areas like acoustics, expertise in deploying perforated sheet metal can solve complex noise control challenges. Perforated panels can be used in conjunction with acoustic backing to manage sound levels effectively in auditoriums, factories, or office spaces, providing a dual function of aesthetic enhancement and noise control. Finally, concerns about maintenance and longevity are common among professionals who are selecting perforated sheet metal. Experience shows that regular maintenance, such as cleaning with appropriate solutions and inspection for wear and tear, extends the life of these materials. Protective coatings can also be applied to certain metals to enhance their durability against environmental stressors, ensuring lasting performance. In conclusion, the optimal use of 4' x 8' perforated sheet metal in products requires a careful balance of material properties, design considerations, and practical application insights. By combining deep industry expertise, real-world experience, and authoritative supplier partnerships, businesses and designers can harness the full potential of this versatile material, ensuring credibility and success in their projects.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP