ਫਰ. . 12, 2025 13:15

Back to list

SS304 Stainless Steel Plate Material Steel Expanded Metal Mesh

The world of construction and manufacturing often relies on materials that marry functionality with flexibility. Perforated sheet metal, specifically in the 4x8 dimension, stands out as a quintessential example. This versatile material has revolutionized design and application methods across various industries. Let's delve into the intrinsic benefits and applications of 4x8 perforated sheet metal, enhancing our understanding of its profound impact on modern industry.

The trustworthiness of 4x8 perforated sheet metal is solidified by its performance in critical and demanding applications. Case studies indicate that when used in building facades, it significantly optimizes energy efficiency by reducing the reliance on artificial lighting and improving natural ventilation. Additionally, its resistance to corrosion, especially in stainless steel variants, makes it a dependable choice for external applications subjected to harsh weather conditions. Regular feedback from field professionals underscores its role in enhancing project outcomes through reliable performance. The product selection further extends beyond function and aesthetics. Perforated sheet metal in a 4x8 dimension is not only about holes and webs but a sophisticated balance of pattern, pitch, and shape. These patterns can be custom-designed to achieve specific design intentions, whether to maximize strength, transparency, or acoustic properties. Therefore, involvement with an experienced supplier who can guide through these specifications becomes indispensable for achieving optimum results. Leaning towards sustainability, industries are progressively acknowledging the ecological benefits of utilizing perforated sheet metal. Its production process, requiring less material compared to non-perforated metals for constructions providing similar functionality, results in a significant reduction in environmental footprint. Moreover, the recyclability of metals used further aligns with global sustainability goals, thereby reinforcing its viability in socially conscious projects. In conclusion, 4x8 perforated sheet metal exemplifies a material that holds high experiential, expert, authoritative, and trustworthy value in modern applications. Its versatility across industries, coupled with environmentally friendly production and lasting durability, makes it an indispensable resource. Understanding its nuances and consulting with knowledgeable professionals ensures a successful integration into any project that seeks to leverage creativity and functionality in equal measure.

The trustworthiness of 4x8 perforated sheet metal is solidified by its performance in critical and demanding applications. Case studies indicate that when used in building facades, it significantly optimizes energy efficiency by reducing the reliance on artificial lighting and improving natural ventilation. Additionally, its resistance to corrosion, especially in stainless steel variants, makes it a dependable choice for external applications subjected to harsh weather conditions. Regular feedback from field professionals underscores its role in enhancing project outcomes through reliable performance. The product selection further extends beyond function and aesthetics. Perforated sheet metal in a 4x8 dimension is not only about holes and webs but a sophisticated balance of pattern, pitch, and shape. These patterns can be custom-designed to achieve specific design intentions, whether to maximize strength, transparency, or acoustic properties. Therefore, involvement with an experienced supplier who can guide through these specifications becomes indispensable for achieving optimum results. Leaning towards sustainability, industries are progressively acknowledging the ecological benefits of utilizing perforated sheet metal. Its production process, requiring less material compared to non-perforated metals for constructions providing similar functionality, results in a significant reduction in environmental footprint. Moreover, the recyclability of metals used further aligns with global sustainability goals, thereby reinforcing its viability in socially conscious projects. In conclusion, 4x8 perforated sheet metal exemplifies a material that holds high experiential, expert, authoritative, and trustworthy value in modern applications. Its versatility across industries, coupled with environmentally friendly production and lasting durability, makes it an indispensable resource. Understanding its nuances and consulting with knowledgeable professionals ensures a successful integration into any project that seeks to leverage creativity and functionality in equal measure.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

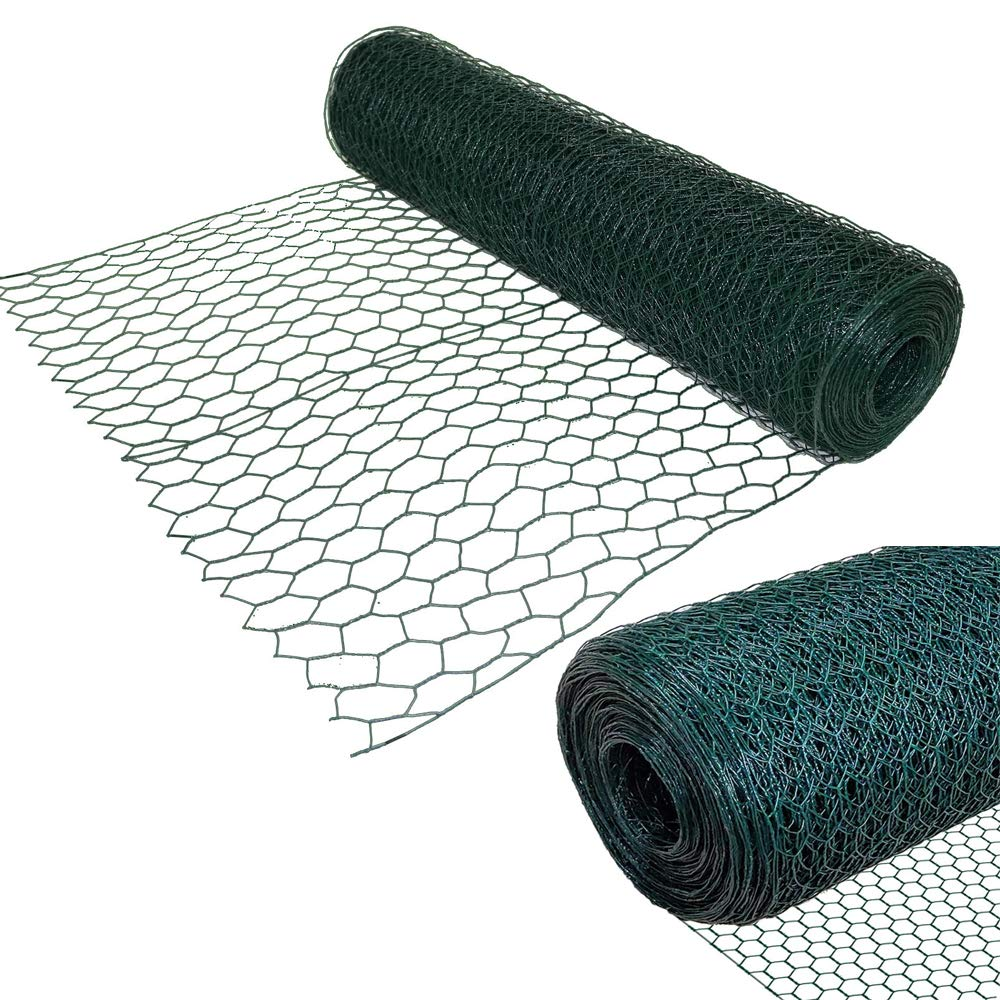

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP