The Innovative Wave of Flowforge Grating Technology

In the ever-evolving field of optical engineering, flowforge grating technology stands at the forefront, offering a novel approach to the manipulation of light. Gratings are essential components in various optical applications, and the advent of flowforge technology has significantly enhanced their performance and versatility.

Flowforge grating technology is built upon the principles of diffraction, where light is bent and spread into its constituent wavelengths as it passes through or reflects off a grating. Traditional gratings are typically made from materials like glass or plastic and manufactured through time-consuming processes such as ruling or molding. However, flowforge technology introduces a new method that combines precision engineering with innovative fabrication techniques, allowing for the creation of gratings with unmatched accuracy and flexibility.

One of the standout features of flowforge gratings is their ability to be customized for specific applications. The traditional limitations of gratings are often rooted in their fixed designs, which can restrict their functionality in dynamic environments. Flowforge gratings, on the other hand, can be tailored to meet the precise requirements of a project, whether it is in telecommunications, spectroscopy, or imaging systems. This customization can include variations in wavelength range, groove density, and material properties, facilitating a broader range of applications.

The manufacturing process of flowforge gratings is designed to improve efficiency and reduce waste

. By leveraging advanced digital fabrication techniques, flowforge technology enables rapid prototyping and scaling of production without compromising quality. This means that researchers and engineers can iterate their designs quickly, testing new concepts and refining them based on real-world performance data. The result is a faster innovation cycle, propelling advancements in fields that rely heavily on precise optical components.flowforge grating

Moreover, flowforge gratings offer superior performance characteristics compared to their conventional counterparts. The enhanced surface quality and structural integrity of flowforge gratings contribute to better light transmission and reduced scattering, resulting in clearer and more accurate optical signals. This is particularly crucial in high-stakes environments such as medical imaging or scientific research, where even the slightest loss of signal fidelity can lead to erroneous interpretations.

Another significant advantage of this technology is its potential for integration with other optical systems. As industries increasingly adopt fiber optics and photonic devices, the need for compatible components grows. Flowforge gratings can be seamlessly integrated into these larger systems, providing a cohesive solution that enhances overall performance. This interoperability is a key factor driving the adoption of flowforge gratings across various sectors.

In addition to their technical advantages, flowforge gratings also align with the growing demand for sustainable practices in manufacturing. By minimizing waste during production and utilizing materials that are increasingly eco-friendly, this technology supports the global push toward greener solutions. This adherence to sustainability not only benefits the environment but also appeals to consumers who are becoming more conscious of the impact of their purchases.

In conclusion, flowforge grating technology represents a significant leap forward in optical engineering. With its customizable features, efficient manufacturing process, superior performance, and environmental sustainability, it is poised to revolutionize the way optical components are designed and utilized. As industries continue to seek ways to optimize their optical systems, flowforge technology will undoubtedly play a pivotal role in shaping the future of light manipulation. Whether in telecommunications, research, or consumer electronics, the potential applications of flowforge gratings are limitless, heralding a new era in the world of optics.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

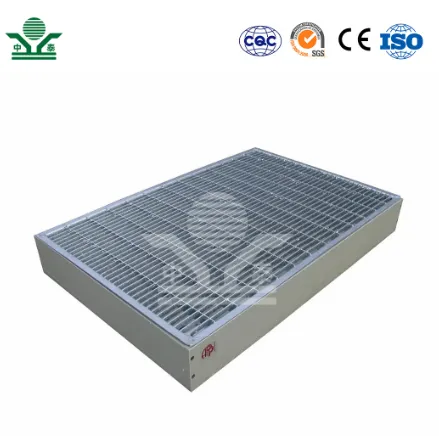

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.