feb . 10, 2025 23:58

Back to list

Punching Hole Wire Mesh China Suppliers Perforated Sheet Metal

Investing in perforated metal sheets requires a solid understanding of the factors affecting their price. This comprehensive guide taps into industry expertise, real-world experience, and authoritative insights to help you navigate the market of perforated sheets with confidence and trust.

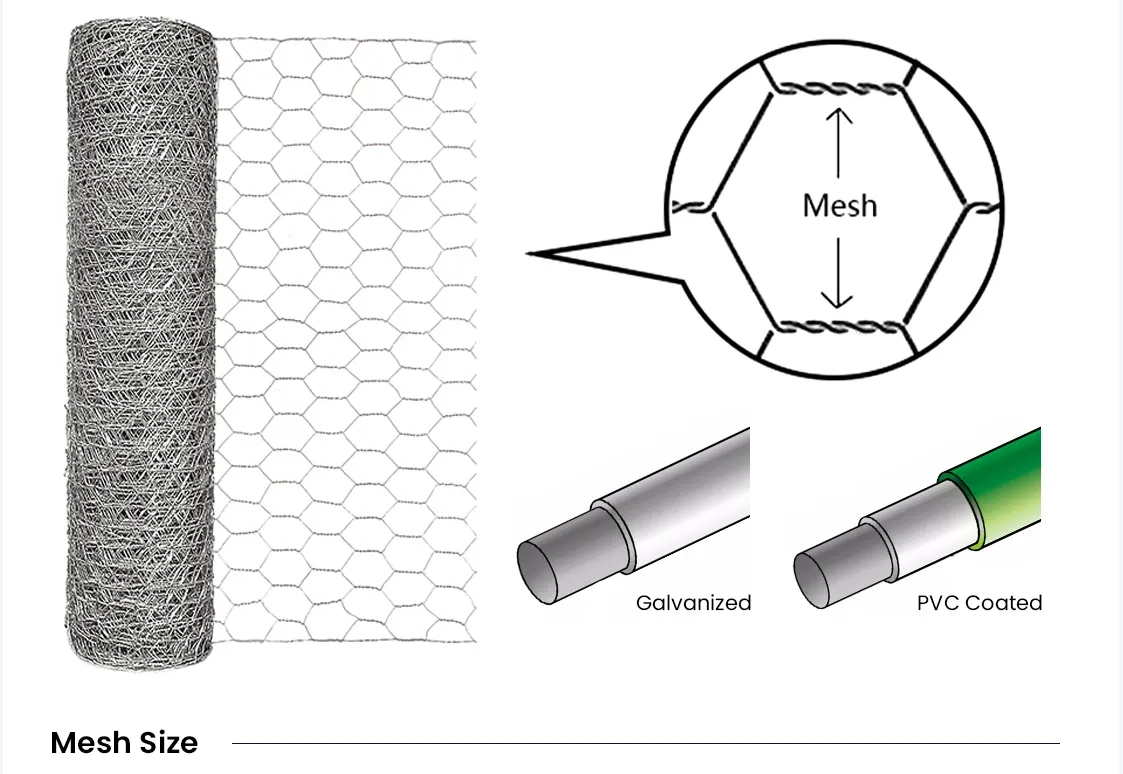

Surface treatment and finishing processes such as galvanization, painting, or powder coating contribute to the cost as well. These treatments enhance both the durability and aesthetic appeal of the sheets, thus increasing their value. Understanding these nuances, one might wonder how to achieve the best price without compromising on quality. The answer lies in selecting reputable suppliers whose pricing reflects their commitment to quality and industry standards. A trustworthy supplier can offer expert advice tailored to your specific needs, helping you navigate the myriad options available. Considerations around sustainability are also increasingly relevant. Opting for suppliers that use environmentally friendly production methods might incur higher initial costs, but these can be offset by potential long-term savings through grants, certifications, and improved company reputation, especially for businesses keen on bolstering their eco-credentials. Moreover, it's crucial to stay informed on market trends. Raw material costs can fluctuate significantly due to geopolitical factors, trade policies, and demand-supply dynamics. Engaging with industry reports, supplier communications, and market analysis is vital for anticipating price changes and planning purchases strategically. In conclusion, the price of perforated sheets is influenced by a plethora of factors ranging from material choice and sheet thickness to pattern complexity and order volume. By understanding these aspects and their impact on cost, you are better positioned to make informed decisions that align with your goals, budget, and project requirements. Establishing partnerships with reliable suppliers and staying attuned to market dynamics enhances your ability to procure quality products at competitive prices.

Surface treatment and finishing processes such as galvanization, painting, or powder coating contribute to the cost as well. These treatments enhance both the durability and aesthetic appeal of the sheets, thus increasing their value. Understanding these nuances, one might wonder how to achieve the best price without compromising on quality. The answer lies in selecting reputable suppliers whose pricing reflects their commitment to quality and industry standards. A trustworthy supplier can offer expert advice tailored to your specific needs, helping you navigate the myriad options available. Considerations around sustainability are also increasingly relevant. Opting for suppliers that use environmentally friendly production methods might incur higher initial costs, but these can be offset by potential long-term savings through grants, certifications, and improved company reputation, especially for businesses keen on bolstering their eco-credentials. Moreover, it's crucial to stay informed on market trends. Raw material costs can fluctuate significantly due to geopolitical factors, trade policies, and demand-supply dynamics. Engaging with industry reports, supplier communications, and market analysis is vital for anticipating price changes and planning purchases strategically. In conclusion, the price of perforated sheets is influenced by a plethora of factors ranging from material choice and sheet thickness to pattern complexity and order volume. By understanding these aspects and their impact on cost, you are better positioned to make informed decisions that align with your goals, budget, and project requirements. Establishing partnerships with reliable suppliers and staying attuned to market dynamics enhances your ability to procure quality products at competitive prices.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP