Product Description

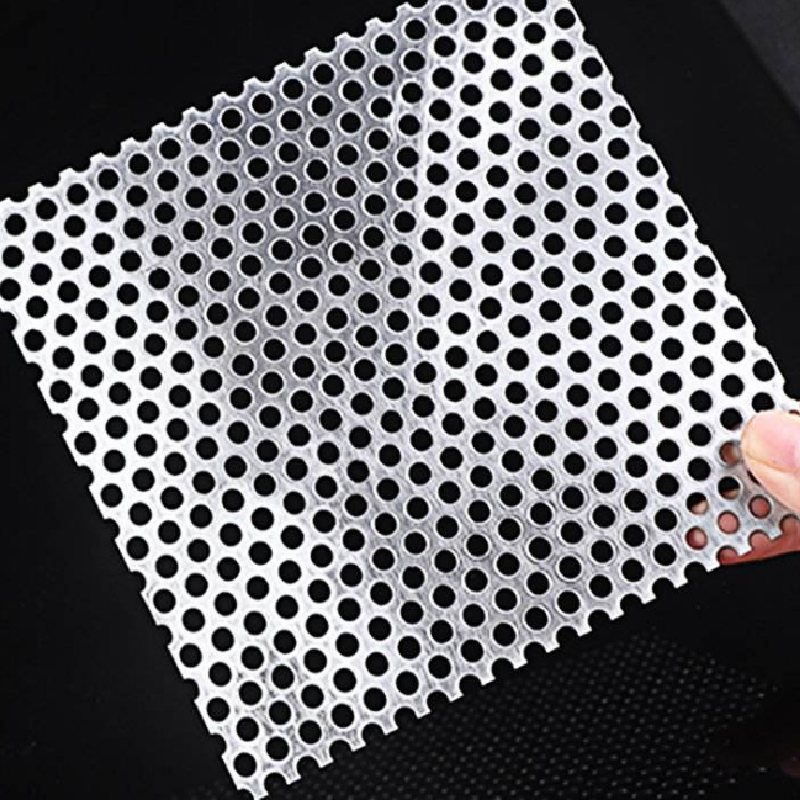

- The hole in the sheet metal consists of three parts, created during the production process:

The structure of the hole: Zone of dents, Cutting zone, Extraction area, Product description.

- Typical sheets are produced with unperforated transverse and longitudinal margins.

There is also the possibility of perforation by customer drawings and sheets with a full perforation field - after consultation. As standard, all sheets are straightened after perforation, in addition, we offer services of further processing of the product, which enables customers to purchase ready-made components.

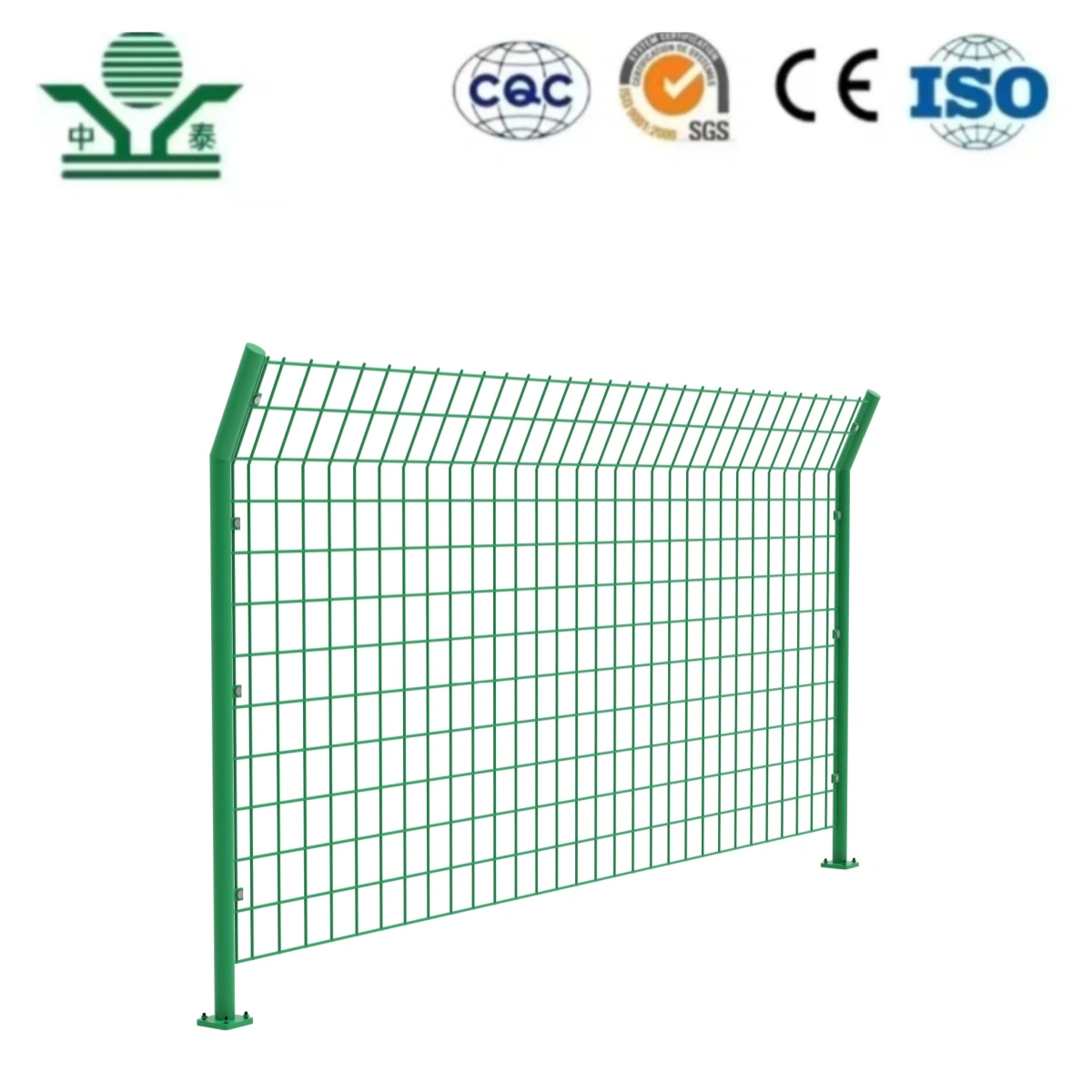

Application

- Perforated metal mesh is widely used in chemical machinery, Pharmaceutical equipment, food and beverage machines, cigarette machines, harvesters, dry-cleaning machine, ironing table, silencing equipment, refrigeration equipment(central air conditioning), speakers, crafts, papermaking, hydraulic fittings, filtration equipment and other industries.

Technical parameters

Material: ordinary steel, abrasion-resistant, heat-resistant, stainless, acid

resistant, aluminum, copper, brass, bronze, plastics, rubbers.

Format:

thickness up to 18 mm, width up to 2.000 mm, length up to 6,000 mm. For some assortments, it is possible to perforate the coils in the coils (coil width Format: up to 1600 mm).

For individual types of perforations, there may be restrictions on the thickness and width of the sheet and the need to leave unperforated technological margins.

Detailed Photos

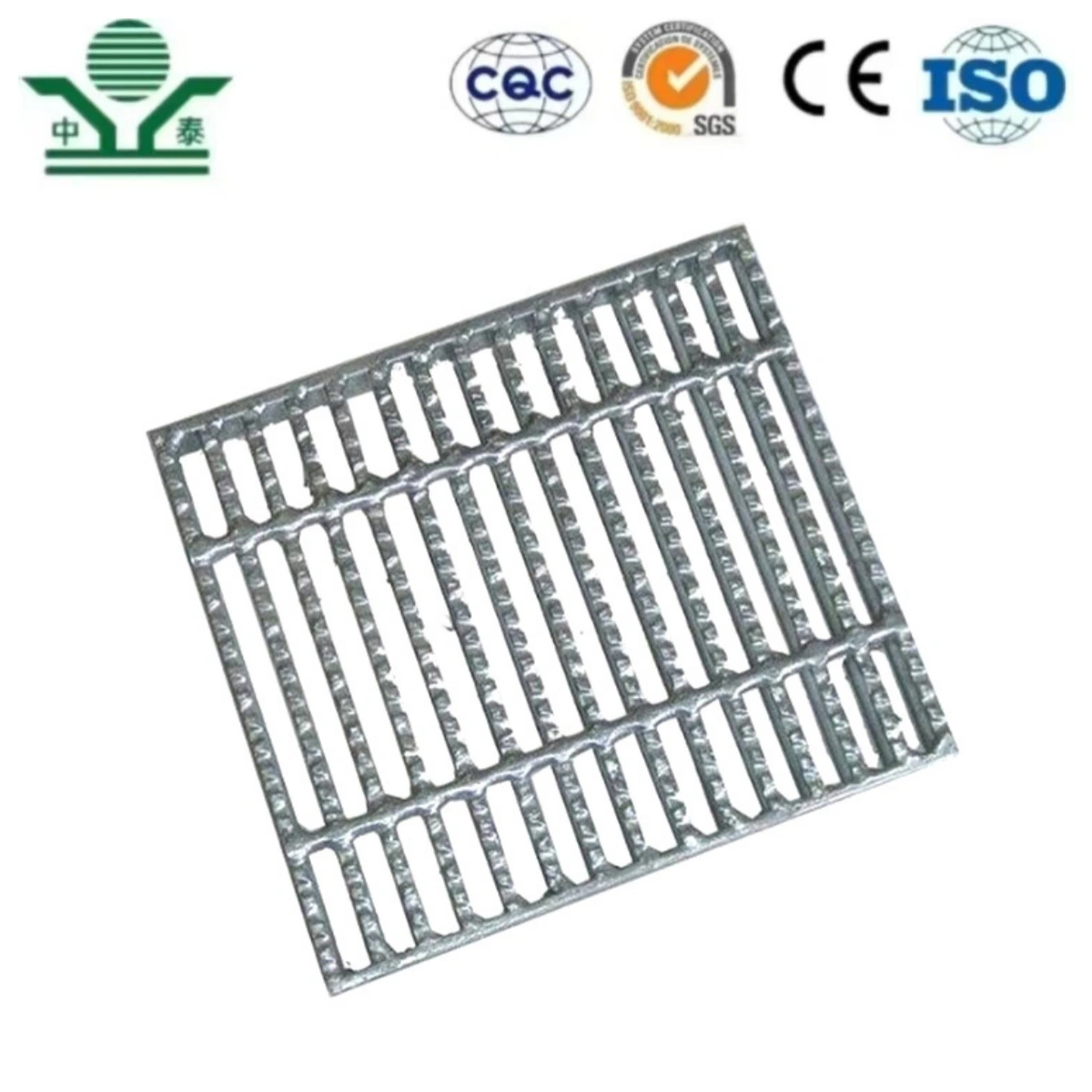

Standard operations

single straightening, cutting to size, and packing on pallets.

Additional operations: bending, rolling, pressing, trapezoidal, framing, welding, welding, powder coating, wiping/cleaning with oil, etc.