The Role of Industrial Floor Grating in Modern Manufacturing

In the realm of modern manufacturing and industrial facilities, the significance of floor grating cannot be underestimated. Industrial floor grating serves as a critical component, ensuring safety, efficiency, and durability in various environments such as factories, warehouses, chemical plants, and power generation stations. This article delves into the key aspects and advantages of industrial floor grating, highlighting its essential role in contemporary settings.

What is Industrial Floor Grating?

Industrial floor grating is a type of flooring system primarily made from materials such as steel, fiberglass, or aluminum. Designed with an open grid configuration, grating allows for the easy passage of liquids, light, and air while providing the necessary structural support for heavy loads. The design inherently enhances safety by minimizing slip hazards and facilitating drainage, making it ideal for environments prone to spills or exposure to chemicals.

Safety Features

One of the most critical factors in any industrial setting is safety. Industrial floor grating provides a slip-resistant surface that reduces the likelihood of accidents. The open design not only allows for quick drainage of spills but also permits debris to fall through, further minimizing the risks associated with slippery surfaces. Moreover, many types of grating are treated with special coatings to enhance their slip resistance and withstand corrosive environments, ensuring a safe working platform for employees.

Durability and Maintenance

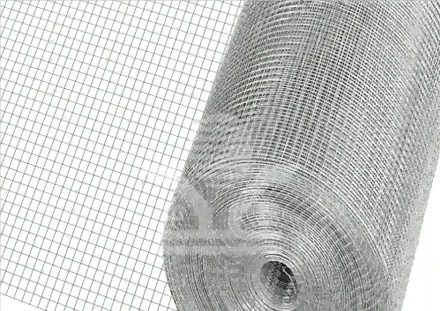

industrial floor grating

The durability of industrial floor grating makes it a cost-effective choice for many manufacturers. Made from robust materials, such as galvanized steel or high-density fiberglass, these gratings can withstand heavy loads, extreme temperatures, and corrosive substances. The long lifespan of industrial floor grating reduces the need for frequent replacements, resulting in lower long-term costs. Additionally, maintenance is relatively straightforward; regular cleaning and periodic inspections can ensure that the grating remains in optimal condition.

Versatility of Applications

Industrial floor grating’s versatility allows it to be used in diverse applications. From heavy machinery areas to walkways and platforms, grating systems can be tailored to meet specific load requirements and environmental conditions. For instance, in wastewater treatment facilities, fiberglass grating is often employed due to its resistance to corrosion and chemical damage. In contrast, steel grating is frequently utilized in areas requiring substantial load-bearing capacity.

Lightweight and Easy Installation

Another advantage of industrial floor grating is its lightweight nature, which facilitates easier handling and installation. The modular design enables quick assembly and disassembly, providing flexibility in layout adjustments or relocations. This is particularly beneficial in manufacturing environments where layout changes are common to improve efficiency or accommodate new machinery.

Conclusion

In conclusion, industrial floor grating plays an indispensable role in enhancing safety, efficiency, and durability in industrial settings. Its slip-resistant properties, ease of maintenance, and versatility cater to the diverse needs of modern manufacturing facilities. The strength and reliability of different grating materials ensure that they can withstand the rigors of industrial use, making them a smart investment for companies looking to improve their operational efficiency and workplace safety. As industries continue to evolve and adapt to new challenges, the importance of reliable flooring solutions like industrial floor grating will undoubtedly remain paramount.

-

Food-Grade BBQ Crimped Wire Mesh: Durable, High-Temp Grilling

NewsAug.31,2025

-

Zhongtai High-Quality 3D Bending Security Welded Mesh Fence

NewsAug.30,2025

-

Premium Perforated Metal Mesh Sheet | Custom Panels

NewsAug.29,2025

-

Zhongtai G325/40/50 Heavy Duty Platform Steel Grating for Sale

NewsAug.28,2025

-

Hexagonal Expanded Metal Versatility for Modern Projects

NewsAug.22,2025

-

Premium Steel Trench Drain Grates for Global Infrastructure Projects

NewsAug.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.