The Importance of Perforated Sheets A Comprehensive Overview

Perforated sheets have become an essential material in various industries due to their versatility, aesthetic appeal, and functional benefits. These sheets, characterized by a series of holes punched into them, are manufactured from a variety of materials, including metals, plastics, and composites. The demand for perforated sheets has led to a rise in suppliers specializing in this product, making it easier for businesses to access high-quality materials suited to their specific needs.

Understanding Perforated Sheets

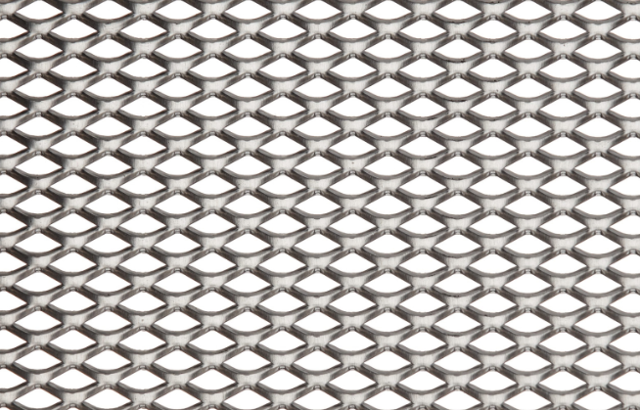

Perforated sheets are flat panels that contain a pattern of holes that can vary in size, shape, and arrangement. The perforation process involves punching holes into the material using specialized machinery, allowing for a wide range of customization. These sheets are available in different thicknesses and materials, making them suitable for a variety of applications, from architectural designs to industrial uses.

Applications of Perforated Sheets

The versatility of perforated sheets means they are used in countless applications across different sectors

1. Architectural Design In modern architecture, perforated sheets are often used for facades, ceilings, and wall partitions. Their ability to allow light and air to pass through while maintaining privacy and aesthetics makes them an attractive choice for designers.

2. Industrial Filtration In manufacturing and processing environments, perforated sheets are critical components in filtration systems. They help separate solids from liquids or gases, ensuring that products meet quality standards.

3. Sound Absorption Perforated sheets are also used in acoustic panels to enhance sound quality in theaters, auditoriums, and recording studios. The design of the holes allows sound waves to pass through, reducing noise levels and improving clarity.

4. Protection and Safety In various industrial settings, perforated sheets act as guards or barriers, protecting workers from harmful materials or preventing accidents. Their durable nature allows them to withstand harsh environments.

perforated sheets suppliers

5. Catering and Food Services In commercial kitchens, perforated trays and sheets are used for grilling, baking, and frying. The holes allow for even heat distribution and draining of excess oils, leading to improved cooking outcomes.

Choosing the Right Supplier

With the increasing demand for perforated sheets, selecting the right supplier is crucial for ensuring quality and reliability. When choosing a supplier, consider the following factors

- Quality Assurance Look for suppliers that adhere to stringent quality control processes. Certification and compliance with industry standards can indicate a commitment to providing high-quality products.

- Customization Options A reliable supplier will offer a range of customization options, such as different hole patterns, sizes, and material types. This flexibility allows businesses to obtain products tailored to their specific requirements.

- Lead Times and Delivery Timely delivery is crucial in maintaining operational efficiency. Ensure that the supplier has a track record of meeting deadlines and can accommodate urgent orders if necessary.

- Customer Support A good supplier will provide excellent customer service and technical support, helping clients through the selection process and addressing any concerns.

- Competitive Pricing While quality should be a priority, it’s also important to consider pricing. Comparing quotes from multiple suppliers can help you find the best deal without compromising on quality.

In conclusion, perforated sheets are invaluable in numerous industries, providing functional benefits that enhance efficiency and aesthetics. As businesses look to suppliers for these essential materials, focusing on quality, customization, and service can lead to successful partnerships that drive innovation and growth. Whether for architectural applications or industrial uses, the right perforated sheets can make all the difference in achieving optimal results.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.