When it comes to industrial applications, platform steel grating is a fundamental component that ensures safety and efficiency. This type of grating is commonly used in walkways, platforms, and various industrial settings where strength and durability are paramount. The design of platform steel grating involves careful consideration of bar thickness and spacing, which directly impact its load-bearing capacity, comfort for users, and overall cost-effectiveness.

The thickness of the bars in platform steel grating plays a crucial role in determining its strength. Thicker bars generally provide greater load-bearing capacity, making them suitable for heavy-duty applications. However, increasing the thickness can also lead to higher material costs, which is a significant consideration for businesses operating on tight budgets. Conversely, thinner bars may reduce costs but can compromise strength, especially in high-traffic areas or environments where heavy machinery operates. Thus, achieving the right balance between thickness and cost is essential for maximizing performance without overspending.

Additionally, the spacing between bars in industrial walkway grating affects both comfort and safety. Wider spacing can lead to discomfort for users, particularly in high-traffic areas where individuals may be walking for extended periods. On the other hand, closer spacing can enhance comfort but may increase material costs. Therefore, understanding the specific requirements of each application is vital for making informed decisions regarding bar thickness and spacing. By offering a range of platform steel grating options, our company ensures that clients can select products tailored to their unique needs, optimizing both performance and budget considerations.

The Role of Industrial Walkway Grating in Safety and Efficiency

Industrial walkway grating is essential for creating safe pathways in various environments, from manufacturing facilities to warehouses. This type of grating is designed to withstand heavy foot traffic and equipment loads while providing excellent drainage and ventilation. The bar thickness and spacing in industrial walkway grating significantly influence its overall effectiveness in these roles.

Thicker bars in industrial walkway grating enhance strength and durability, making them ideal for areas subjected to heavy loads. However, businesses must also consider the implications of increased weight and cost. A well-designed grating system balances these factors, ensuring safety without incurring unnecessary expenses. Moreover, the spacing between bars affects both the aesthetic appeal and functionality of the walkway. Wider spacing may allow for better drainage but can compromise user comfort, particularly if individuals are required to stand for extended periods.

Our company specializes in providing high-quality industrial walkway grating that meets diverse needs. By carefully selecting the appropriate bar thickness and spacing, clients can ensure that their walkways are not only safe but also comfortable for daily use. Additionally, our grating options are designed to resist corrosion and wear, further enhancing their longevity and reducing maintenance costs. Investing in the right industrial walkway grating is crucial for companies looking to optimize their operational efficiency while maintaining a safe environment for employees and visitors alike.

Exploring the Benefits of Metal Grate Platforms

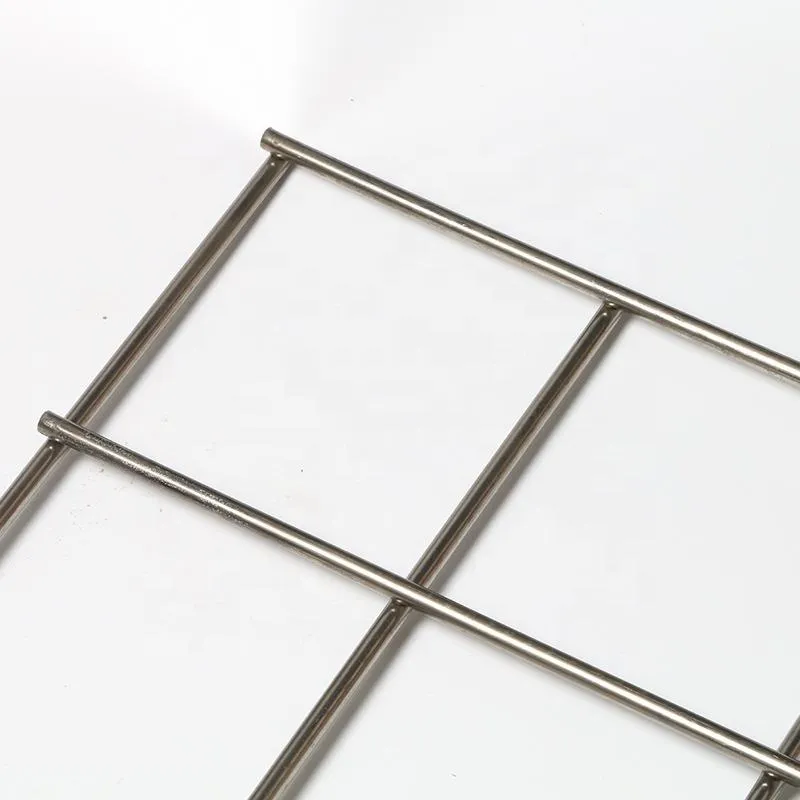

Metal grate platforms are increasingly popular in various industries due to their versatility and strength. These platforms are constructed using high-quality steel grating, which provides excellent support while allowing for efficient drainage and airflow. The choice of bar thickness and spacing in metal grate platforms is crucial to ensuring optimal performance in different applications.

Thicker bars in metal grate platforms offer enhanced load-bearing capabilities, making them suitable for heavy machinery and equipment. However, businesses must weigh the benefits of increased strength against the associated costs. Thicker bars can lead to higher production expenses, which may not be justifiable for all applications. Conversely, opting for thinner bars can reduce costs but may compromise the platform's ability to support heavy loads. Therefore, careful consideration of the specific requirements of each project is essential.

The spacing of the bars in metal grate platforms also plays a significant role in user experience. Wider spacing can facilitate drainage and airflow, which is particularly beneficial in environments where spills are common. However, this can lead to discomfort for individuals walking on the platform, especially if they are wearing inappropriate footwear. Our company offers a variety of metal grate platform options, allowing clients to select the ideal combination of bar thickness and spacing to meet their unique needs. By prioritizing both strength and comfort, businesses can enhance productivity while ensuring safety for their employees.

The Cost Implications of Bar Grating Platforms

When considering bar grating platforms, understanding the cost implications of bar thickness and spacing is essential for making informed purchasing decisions. The initial investment in grating systems can vary significantly based on the materials used and the design specifications. Thicker bars generally result in higher material costs, while wider spacing can lead to increased manufacturing expenses. Therefore, striking a balance between cost and performance is crucial for businesses aiming to optimize their budgets.

One important aspect to consider is the long-term value of investing in quality bar grating platforms. While cheaper alternatives may seem attractive initially, they often lead to increased maintenance costs and potential safety hazards. Thicker bars and closer spacing provide greater durability and safety, ultimately reducing the need for frequent replacements or repairs. Our company emphasizes the importance of selecting high-quality products that align with industry standards, ensuring that clients receive maximum value for their investment.

Additionally, the cost of bar grating platforms can be influenced by factors such as customization options and production timelines. Businesses looking to implement tailored solutions may incur additional costs, but the benefits of having grating systems that meet their specific requirements often outweigh these expenses. By providing a range of customizable options, our company allows clients to find the perfect balance between performance, comfort, and cost, ensuring that their projects are completed successfully and within budget.

FAQs: Understanding Bar Thickness and Spacing in Steel Grating

What is platform steel grating used for?

Platform steel grating is used in various industrial applications to create safe walkways and platforms, providing strength and durability while allowing for drainage and ventilation.

How does bar thickness affect industrial walkway grating?

Bar thickness impacts the load-bearing capacity of industrial walkway grating. Thicker bars provide more strength, making them suitable for heavy-duty applications.

What are the benefits of using metal grate platforms?

Metal grate platforms offer excellent support, drainage, and airflow, making them versatile for various applications while ensuring user safety and comfort.

How do I choose the right spacing for bar grating platforms?

Choosing the right spacing involves considering factors such as comfort, drainage needs, and the specific requirements of your application to ensure optimal performance.

Are thicker bars always better for steel grating?

Not necessarily. While thicker bars provide greater strength, they can also increase costs. It's essential to balance thickness with the specific needs of your project.

Explore Our Premium Steel Grating Products Today

Invest in high-quality platform steel grating, industrial walkway grating, metal grate platforms, and bar grating platforms from our company. Visit our website to browse our extensive range of products and place your order today. Ensure safety and efficiency in your projects with our superior steel grating solutions!

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.