Feb . 13, 2025 10:40

Back to list

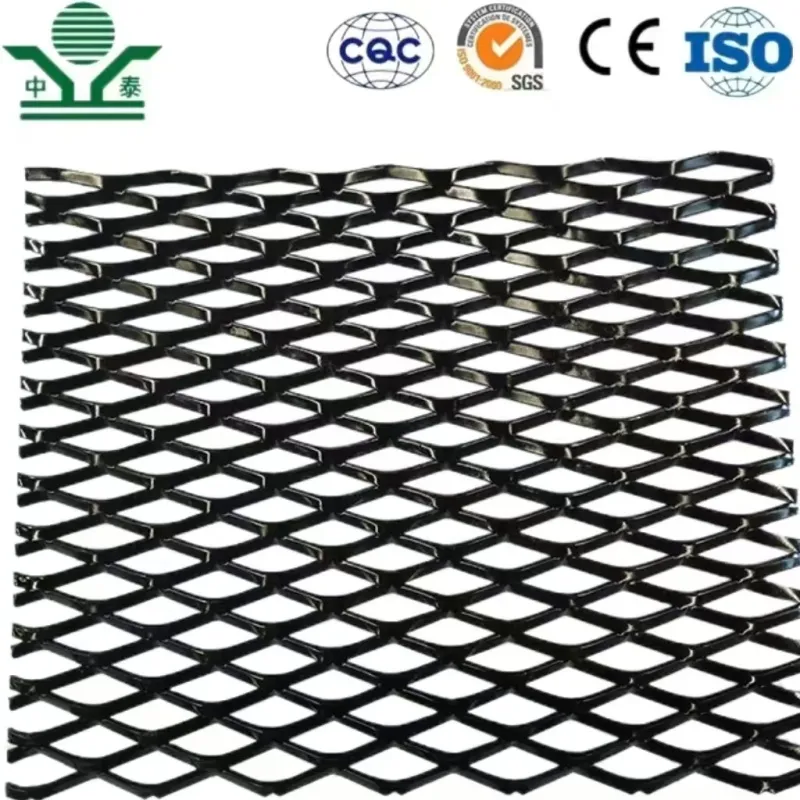

square mesh screen

Square mesh screens are essential components in various industries, providing versatile solutions for filtration, separation, and securing areas. Their unique design combines durability with functionality, making them an invaluable tool across multiple applications. When selecting a square mesh screen, it's crucial to understand its features and benefits to make an informed decision.

Safety considerations are another critical factor when implementing square mesh screens. The choice of material and mesh size plays a significant role in ensuring that the screen meets safety standards for a given application. For instance, when used in construction, selecting a mesh that prevents debris from falling while allowing airflow is crucial to ensuring the safety of workers and the public. Innovation in the production of square mesh screens has led to advancements in customization options. Today, manufacturers offer bespoke solutions tailored to specific industry needs, optimizing screen performance across various applications. This customization ranges from adjustments in mesh size and wire diameter to the use of specialized coatings that enhance the screen's properties for particular environments. Environmental considerations have also affected the design and use of square mesh screens. With increasing emphasis on sustainability, manufacturers are adopting eco-friendly practices in the production of these screens. Utilizing recyclable materials and implementing energy-efficient processes not only aligns with global environmental goals but also provides businesses with a more sustainable choice that aligns with their corporate responsibility initiatives. In conclusion, the versatility and resilience of square mesh screens make them indispensable. Their application across different sectors confirms their adaptability and reliability. By opting for high-quality materials and understanding the specific needs of their use, businesses can leverage the full benefits these screens offer. As industries continue to evolve, the demand for effective and efficient solutions like square mesh screens will undoubtedly rise, reaffirming their critical role in modern industrial and architectural applications.

Safety considerations are another critical factor when implementing square mesh screens. The choice of material and mesh size plays a significant role in ensuring that the screen meets safety standards for a given application. For instance, when used in construction, selecting a mesh that prevents debris from falling while allowing airflow is crucial to ensuring the safety of workers and the public. Innovation in the production of square mesh screens has led to advancements in customization options. Today, manufacturers offer bespoke solutions tailored to specific industry needs, optimizing screen performance across various applications. This customization ranges from adjustments in mesh size and wire diameter to the use of specialized coatings that enhance the screen's properties for particular environments. Environmental considerations have also affected the design and use of square mesh screens. With increasing emphasis on sustainability, manufacturers are adopting eco-friendly practices in the production of these screens. Utilizing recyclable materials and implementing energy-efficient processes not only aligns with global environmental goals but also provides businesses with a more sustainable choice that aligns with their corporate responsibility initiatives. In conclusion, the versatility and resilience of square mesh screens make them indispensable. Their application across different sectors confirms their adaptability and reliability. By opting for high-quality materials and understanding the specific needs of their use, businesses can leverage the full benefits these screens offer. As industries continue to evolve, the demand for effective and efficient solutions like square mesh screens will undoubtedly rise, reaffirming their critical role in modern industrial and architectural applications.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP