Feb . 13, 2025 10:22

Back to list

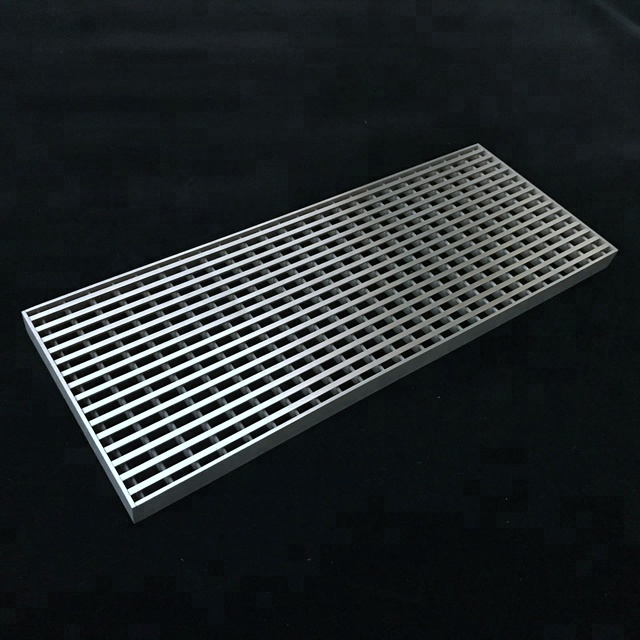

slotted screen mesh

Understanding the pivotal role of slotted screen mesh in a variety of industrial applications unveils how indispensable it has become for enhancing operational efficiencies. Utilized prevalently in industries such as mineral processing, wastewater treatment, and agricultural applications, the slotted screen mesh exemplifies a synergy of durability and precision. Its design caters primarily to sieving, filtering, and protecting processes, ensuring only the desired material passes through.

From an authoritative standpoint, ongoing advancements in manufacturing technology have propelled the production of slotted screen mesh to new heights. Incorporating cutting-edge techniques such as laser cutting and plasma welding enhances the precision in mesh creation, contributing to its customized design capabilities. These advancements have positioned slotted screen mesh as an innovative leader in efficiency improvement and cost reduction across industrial sectors. The systemic evolution of design and production processes continually enhances the mesh's adaptability to emerging industrial demands. Trustworthiness in choosing the right slotted screen mesh is fundamental, underscoring the need to collaborate with reputable suppliers and manufacturers. As operational success heavily relies on the integrity and performance of slotted mesh, investing in quality assurance and testing procedures ensures reliability. Certifications and compliance with international standards, such as ISO and ASTM, bolster credibility and affirm the mesh's suitability for specified applications. Engaging with suppliers who provide post-installation support and technical guidance plays a pivotal role in optimizing the mesh's integration into existing systems. In summary, the slotted screen mesh stands as a cornerstone of efficiency and reliability across a multitude of industries. Its innovative design, robust material composition, and evolving manufacturing processes underscore its indispensable role in optimizing industrial processes. The fusion of expertise, authority, and trustworthiness in its application not only enhances operational outcomes but also sets a benchmark in quality and performance standards. As industries continue to evolve, the slotted screen mesh remains a steadfast ally in navigating the challenges of modern processing demands.

From an authoritative standpoint, ongoing advancements in manufacturing technology have propelled the production of slotted screen mesh to new heights. Incorporating cutting-edge techniques such as laser cutting and plasma welding enhances the precision in mesh creation, contributing to its customized design capabilities. These advancements have positioned slotted screen mesh as an innovative leader in efficiency improvement and cost reduction across industrial sectors. The systemic evolution of design and production processes continually enhances the mesh's adaptability to emerging industrial demands. Trustworthiness in choosing the right slotted screen mesh is fundamental, underscoring the need to collaborate with reputable suppliers and manufacturers. As operational success heavily relies on the integrity and performance of slotted mesh, investing in quality assurance and testing procedures ensures reliability. Certifications and compliance with international standards, such as ISO and ASTM, bolster credibility and affirm the mesh's suitability for specified applications. Engaging with suppliers who provide post-installation support and technical guidance plays a pivotal role in optimizing the mesh's integration into existing systems. In summary, the slotted screen mesh stands as a cornerstone of efficiency and reliability across a multitude of industries. Its innovative design, robust material composition, and evolving manufacturing processes underscore its indispensable role in optimizing industrial processes. The fusion of expertise, authority, and trustworthiness in its application not only enhances operational outcomes but also sets a benchmark in quality and performance standards. As industries continue to evolve, the slotted screen mesh remains a steadfast ally in navigating the challenges of modern processing demands.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP