Feb . 12, 2025 17:13

Back to list

Micro Perforated Metal Sheet China Factory Thick Plate 20mm Perforated Plate

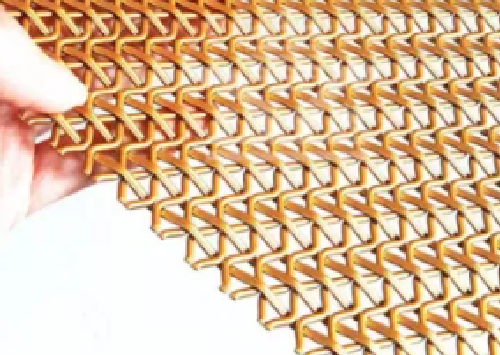

Perforated metal panels are not merely functional; they are a harmonious blend of aesthetics and utility that have found applications in myriad industries worldwide. These panels, characterized by a pattern of holes or perforations, offer multiple benefits ranging from architectural enhancements to industrial solutions.

Moreover, these panels are invaluable in industrial settings. They can be employed as filters or screens to separate particles, control airflow, and provide ventilation in various machinery and processing equipment. Given their strength-to-weight ratio, they offer an efficient and cost-effective solution that can withstand harsh operational conditions. The authoritative nature of perforated metal panels in environmental applications cannot be understated. They contribute to reducing the ecological footprint of buildings by fostering passive airflow and natural temperature regulation. This synergy between functionality and sustainability underscores the growing trend of using perforated panels in eco-friendly and green architecture designs. Trust in the usage of perforated metal panels is bolstered by their proven track record across several sectors. From transport to retail and hospitality to healthcare, stakeholders consistently vouch for their performance. Manufacturers also provide warranties and adherence to international standards, further validating their commitment to quality and reliability. In summary, the exploration of perforated metal panel patterns reveals a versatile, sustainable, and highly functional product category. Their capacity to address multifaceted challenges – from aesthetic design to acoustic and environmental management – renders them indispensable across industries. Whether you're an architect aiming to infuse modern aesthetics into a building or an engineer seeking efficient industrial solutions, perforated metal panels present a sophisticated answer to contemporary demands, backed by expertise, authority, and trustworthiness.

Moreover, these panels are invaluable in industrial settings. They can be employed as filters or screens to separate particles, control airflow, and provide ventilation in various machinery and processing equipment. Given their strength-to-weight ratio, they offer an efficient and cost-effective solution that can withstand harsh operational conditions. The authoritative nature of perforated metal panels in environmental applications cannot be understated. They contribute to reducing the ecological footprint of buildings by fostering passive airflow and natural temperature regulation. This synergy between functionality and sustainability underscores the growing trend of using perforated panels in eco-friendly and green architecture designs. Trust in the usage of perforated metal panels is bolstered by their proven track record across several sectors. From transport to retail and hospitality to healthcare, stakeholders consistently vouch for their performance. Manufacturers also provide warranties and adherence to international standards, further validating their commitment to quality and reliability. In summary, the exploration of perforated metal panel patterns reveals a versatile, sustainable, and highly functional product category. Their capacity to address multifaceted challenges – from aesthetic design to acoustic and environmental management – renders them indispensable across industries. Whether you're an architect aiming to infuse modern aesthetics into a building or an engineer seeking efficient industrial solutions, perforated metal panels present a sophisticated answer to contemporary demands, backed by expertise, authority, and trustworthiness.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP