Feb . 12, 2025 16:43

Back to list

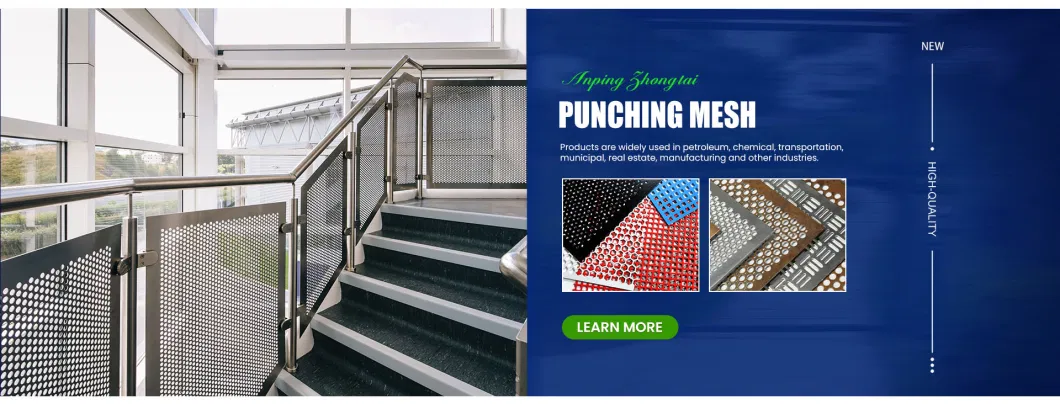

Aluminum Plate Material Expanded Metal Sheet

In the vast realm of construction and design, perforated sheet metal stands apart as a versatile and essential material, embraced across numerous industries for a plethora of applications. Understanding the varied sizes of these sheets can significantly impact their functionality and usability in your projects. Diving into the nuances of perforated sheet sizes isn't just an academic exercise; it's an exploration into optimizing material utility, enhancing aesthetic appeal, and ensuring structural integrity.

Further expanding on the versatility of perforated sheets, custom manufacturing offers bespoke solutions tailored exactly to your project requirements. Advances in CNC machining and laser cutting allow for the precision crafting of perforations and patterns, aligning with the exact specifications of architects, engineers, and designers. This bespoke capability fundamentally transforms how spaces are utilized—from acoustics in concert halls to filtration systems in cleanrooms. Trust in perforated sheet metal stems from its proven track record across diverse industries. Its application in the automotive sector, for example, underlines its practicality in terms of weight reduction and performance improvement, while its presence in the agricultural industry, particularly in grain drying and separation, showcases its utility in enhancing productivity and efficiency. It's essential to source perforated sheets from reputable manufacturers who offer comprehensive support, from material selection to technical guidance on applications. A credible supplier brings to the table not just products but also expertise—vital in optimizing the impact of perforated sheets in your project. In conclusion, understanding perforated sheet sizes extends beyond mere dimensions. It's about tapping into a strategic resource that offers unparalleled flexibility and functionality. The successful application of perforated sheet metal can transform projects, offering solutions that combine aesthetics with efficiency, and practicality with innovation. Choosing the right size for the task at hand is a testament to one's expertise, reflecting a nuanced understanding of both the material and its transformative potential in the right hands.

Further expanding on the versatility of perforated sheets, custom manufacturing offers bespoke solutions tailored exactly to your project requirements. Advances in CNC machining and laser cutting allow for the precision crafting of perforations and patterns, aligning with the exact specifications of architects, engineers, and designers. This bespoke capability fundamentally transforms how spaces are utilized—from acoustics in concert halls to filtration systems in cleanrooms. Trust in perforated sheet metal stems from its proven track record across diverse industries. Its application in the automotive sector, for example, underlines its practicality in terms of weight reduction and performance improvement, while its presence in the agricultural industry, particularly in grain drying and separation, showcases its utility in enhancing productivity and efficiency. It's essential to source perforated sheets from reputable manufacturers who offer comprehensive support, from material selection to technical guidance on applications. A credible supplier brings to the table not just products but also expertise—vital in optimizing the impact of perforated sheets in your project. In conclusion, understanding perforated sheet sizes extends beyond mere dimensions. It's about tapping into a strategic resource that offers unparalleled flexibility and functionality. The successful application of perforated sheet metal can transform projects, offering solutions that combine aesthetics with efficiency, and practicality with innovation. Choosing the right size for the task at hand is a testament to one's expertise, reflecting a nuanced understanding of both the material and its transformative potential in the right hands.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP