Jun . 14, 2024 13:38

Back to list

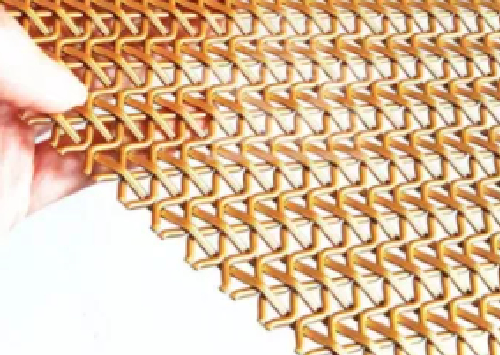

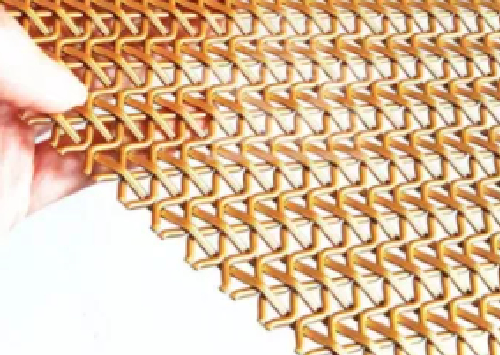

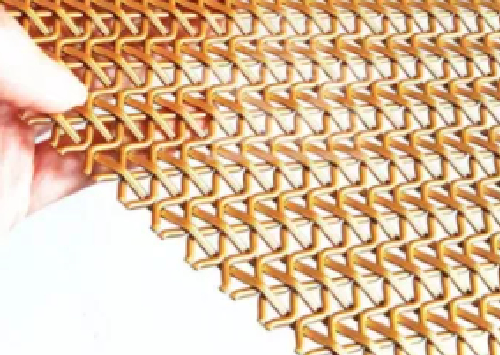

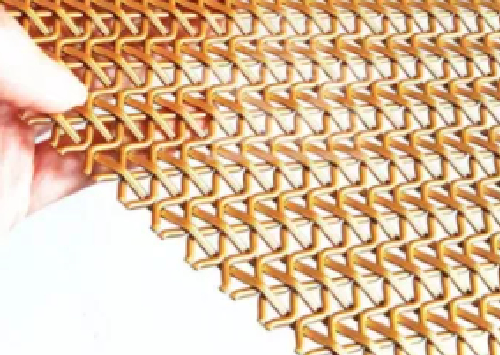

Perforated corrugated iron sheets.

The Versatile Applications of Perforated Corrugated Iron

In the world of modern construction and design, perforated corrugated iron has emerged as a versatile material that combines durability with aesthetic appeal. This innovative take on traditional corrugated iron involves the addition of small, strategically placed holes that not only reduce weight but also allow for various functional uses.

Perforated corrugated iron is manufactured through a process where small holes are punched into the metal sheets. These holes can vary in size and pattern, depending on the intended use of the material. This unique feature makes it an ideal choice for numerous applications, ranging from architectural design to industrial usage.

One of the primary advantages of perforated corrugated iron is its excellent ventilation properties. The perforations allow air to flow through freely, making it suitable for roofing in buildings that require good air circulation, such as greenhouses, livestock shelters, and storage facilities for perishable goods. Furthermore, the inclusion of these holes can significantly reduce wind uplift, enhancing the structural stability of the roof in areas prone to severe weather conditions.

Aside from its functional benefits, perforated corrugated iron also offers a distinctive visual appeal. When used in architectural designs, the patterns formed by the perforations can create interesting shadow effects and light plays, transforming a simple structure into a visually striking piece of art. This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics

This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics perforated corrugated iron.

In industrial settings, perforated corrugated iron is often used in machinery and equipment that requires ventilation or the passage of materials. For example, it can be found in conveyor systems where products need to be cooled or dried during processing. Its heat-resistant properties also make it a preferred material for ovens and furnaces, where ventilation plays a crucial role.

Despite being less robust than its non-perforated counterpart, perforated corrugated iron still maintains considerable strength and durability. It is rust-resistant and can withstand exposure to harsh environments, ensuring longevity even in challenging conditions. Moreover, the reduced weight resulting from the perforations makes it easier to handle during installation and transportation.

Perforated corrugated iron is a testament to the innovation and adaptability within construction and industrial materials. By combining functionality with aesthetics and improving upon traditional corrugated iron, this material has carved out a niche for itself across various industries. As technology continues to advance, it is likely that we will see even more creative uses for perforated corrugated iron, further expanding its applications and benefits.

perforated corrugated iron.

In industrial settings, perforated corrugated iron is often used in machinery and equipment that requires ventilation or the passage of materials. For example, it can be found in conveyor systems where products need to be cooled or dried during processing. Its heat-resistant properties also make it a preferred material for ovens and furnaces, where ventilation plays a crucial role.

Despite being less robust than its non-perforated counterpart, perforated corrugated iron still maintains considerable strength and durability. It is rust-resistant and can withstand exposure to harsh environments, ensuring longevity even in challenging conditions. Moreover, the reduced weight resulting from the perforations makes it easier to handle during installation and transportation.

Perforated corrugated iron is a testament to the innovation and adaptability within construction and industrial materials. By combining functionality with aesthetics and improving upon traditional corrugated iron, this material has carved out a niche for itself across various industries. As technology continues to advance, it is likely that we will see even more creative uses for perforated corrugated iron, further expanding its applications and benefits.

This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics

This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics This has led to its increasing popularity in contemporary designs, where engineers and architects seek to balance utility with aesthetics perforated corrugated iron.

In industrial settings, perforated corrugated iron is often used in machinery and equipment that requires ventilation or the passage of materials. For example, it can be found in conveyor systems where products need to be cooled or dried during processing. Its heat-resistant properties also make it a preferred material for ovens and furnaces, where ventilation plays a crucial role.

Despite being less robust than its non-perforated counterpart, perforated corrugated iron still maintains considerable strength and durability. It is rust-resistant and can withstand exposure to harsh environments, ensuring longevity even in challenging conditions. Moreover, the reduced weight resulting from the perforations makes it easier to handle during installation and transportation.

Perforated corrugated iron is a testament to the innovation and adaptability within construction and industrial materials. By combining functionality with aesthetics and improving upon traditional corrugated iron, this material has carved out a niche for itself across various industries. As technology continues to advance, it is likely that we will see even more creative uses for perforated corrugated iron, further expanding its applications and benefits.

perforated corrugated iron.

In industrial settings, perforated corrugated iron is often used in machinery and equipment that requires ventilation or the passage of materials. For example, it can be found in conveyor systems where products need to be cooled or dried during processing. Its heat-resistant properties also make it a preferred material for ovens and furnaces, where ventilation plays a crucial role.

Despite being less robust than its non-perforated counterpart, perforated corrugated iron still maintains considerable strength and durability. It is rust-resistant and can withstand exposure to harsh environments, ensuring longevity even in challenging conditions. Moreover, the reduced weight resulting from the perforations makes it easier to handle during installation and transportation.

Perforated corrugated iron is a testament to the innovation and adaptability within construction and industrial materials. By combining functionality with aesthetics and improving upon traditional corrugated iron, this material has carved out a niche for itself across various industries. As technology continues to advance, it is likely that we will see even more creative uses for perforated corrugated iron, further expanding its applications and benefits. Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP