Jun . 16, 2024 10:40

Back to list

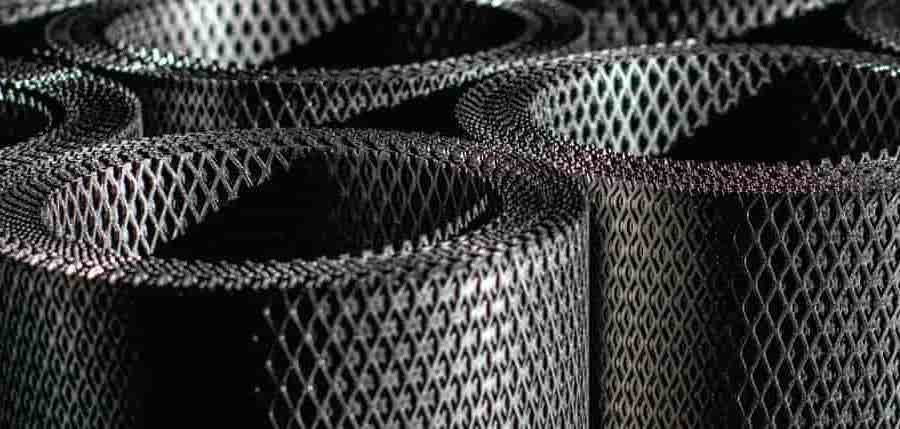

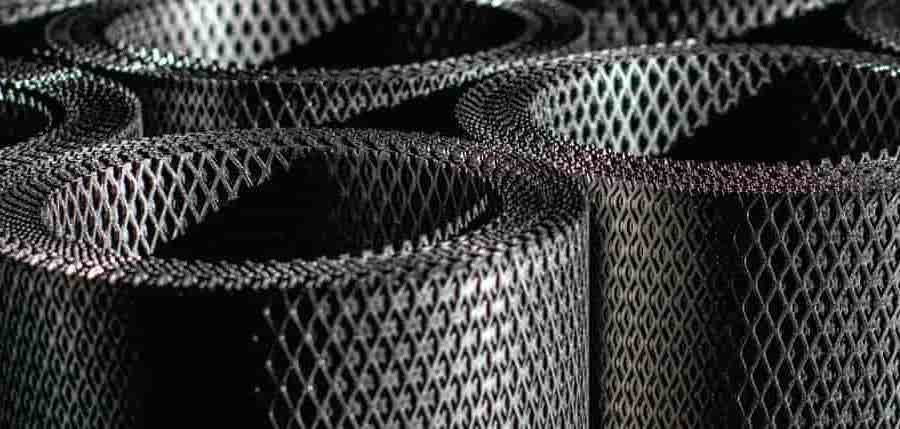

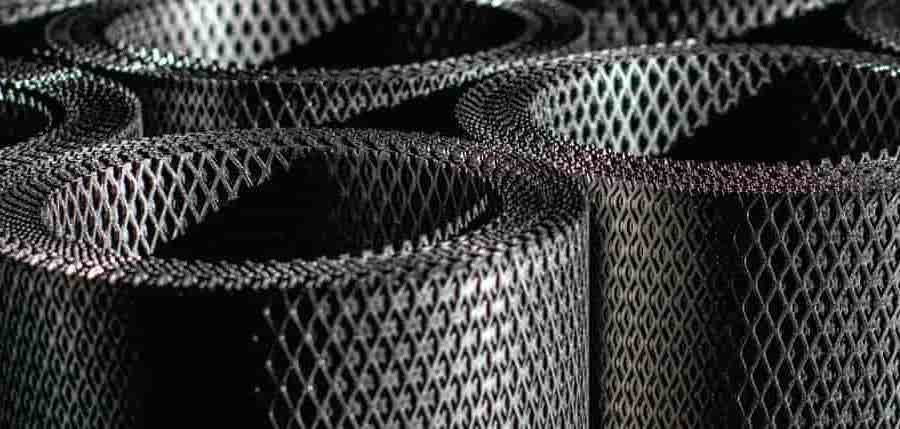

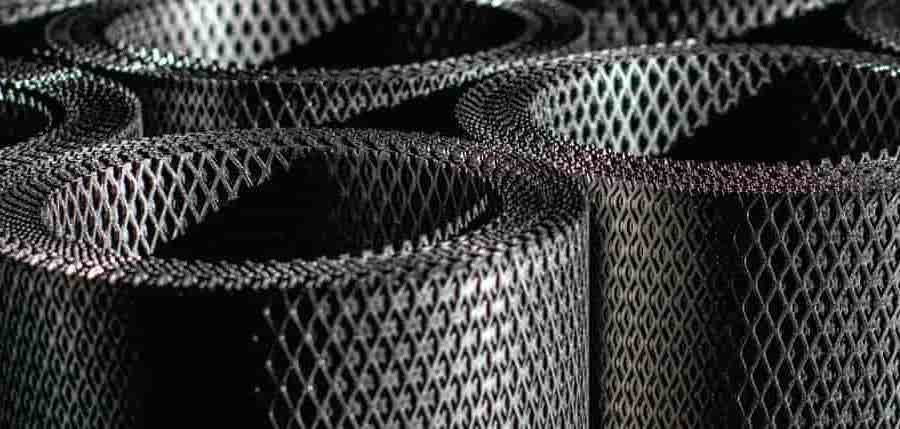

Perforated carbon steel sheet with high strength.

Carbon steel perforated sheets are an essential component in various industries due to their unique properties and versatility. These sheets are made from carbon steel, which is an alloy of iron and carbon, and are characterized by their durability, strength, and resistance to corrosion. The perforations in these sheets allow for the passage of air, liquids, or other materials, making them ideal for a wide range of applications.

One of the most common uses of carbon steel perforated sheets is in the construction industry. They are often used as filters or grates in drainage systems, allowing water to flow through while preventing debris from entering the system. Additionally, they can be used as ventilation grilles in buildings, providing adequate airflow without compromising security.

In the automotive industry, carbon steel perforated sheets are used in the manufacturing of car engines. The perforations allow for the circulation of coolant and oil, ensuring that the engine remains at an optimal temperature during operation. They are also used in the production of exhaust systems, where they help to reduce noise levels by absorbing sound waves.

Another application of carbon steel perforated sheets is in the agricultural sector. They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators

They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators carbon steel perforated sheet. Furthermore, they can be used as crop protection screens, protecting crops from pests and adverse weather conditions.

The manufacturing process of carbon steel perforated sheets involves several steps. Firstly, the raw material is cut into sheets of the desired size and shape. Then, holes are punched into the sheet using specialized machinery. Finally, the sheet is cleaned and treated to improve its resistance to corrosion and extend its lifespan.

In conclusion, carbon steel perforated sheets are a versatile and durable material with numerous applications across various industries. Their unique properties make them ideal for use in construction, automotive, agriculture, and many other sectors. As technology continues to advance, it is likely that we will see even more innovative uses for this remarkable material.

carbon steel perforated sheet. Furthermore, they can be used as crop protection screens, protecting crops from pests and adverse weather conditions.

The manufacturing process of carbon steel perforated sheets involves several steps. Firstly, the raw material is cut into sheets of the desired size and shape. Then, holes are punched into the sheet using specialized machinery. Finally, the sheet is cleaned and treated to improve its resistance to corrosion and extend its lifespan.

In conclusion, carbon steel perforated sheets are a versatile and durable material with numerous applications across various industries. Their unique properties make them ideal for use in construction, automotive, agriculture, and many other sectors. As technology continues to advance, it is likely that we will see even more innovative uses for this remarkable material.

They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators

They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators They are commonly used as animal cages or enclosures, providing sufficient ventilation while keeping animals safe from predators carbon steel perforated sheet. Furthermore, they can be used as crop protection screens, protecting crops from pests and adverse weather conditions.

The manufacturing process of carbon steel perforated sheets involves several steps. Firstly, the raw material is cut into sheets of the desired size and shape. Then, holes are punched into the sheet using specialized machinery. Finally, the sheet is cleaned and treated to improve its resistance to corrosion and extend its lifespan.

In conclusion, carbon steel perforated sheets are a versatile and durable material with numerous applications across various industries. Their unique properties make them ideal for use in construction, automotive, agriculture, and many other sectors. As technology continues to advance, it is likely that we will see even more innovative uses for this remarkable material.

carbon steel perforated sheet. Furthermore, they can be used as crop protection screens, protecting crops from pests and adverse weather conditions.

The manufacturing process of carbon steel perforated sheets involves several steps. Firstly, the raw material is cut into sheets of the desired size and shape. Then, holes are punched into the sheet using specialized machinery. Finally, the sheet is cleaned and treated to improve its resistance to corrosion and extend its lifespan.

In conclusion, carbon steel perforated sheets are a versatile and durable material with numerous applications across various industries. Their unique properties make them ideal for use in construction, automotive, agriculture, and many other sectors. As technology continues to advance, it is likely that we will see even more innovative uses for this remarkable material. Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP