I. Preparation for Weaving

Before the production of stainless steel woven wire mesh, certain preparatory steps are necessary. Firstly, it is essential to inspect the machinery and equipment for functionality, determine the specifications and dimensions of the stainless steel mesh to be woven, and gather the necessary materials and tools.

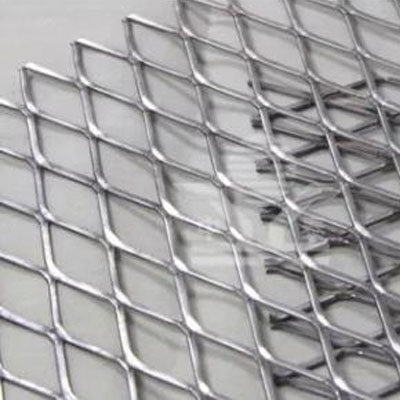

Stainless Steel Plate Material Galvanized Expanded Metal Mesh

II. Mesh Design

According to the requirements, proceed with the design of the stainless steel mesh. During the design phase, factors such as mesh density, size, shape, and others need to be considered to meet various usage demands. Simultaneously, it is essential to determine the mesh design scheme based on the specifications and dimensions of the Stainless steel woven mesh.

III. Material Selection

Stainless steel wire is the primary material used in weaving stainless steel wire mesh, while common materials for producing woven wire mesh include low carbon steel wire, nickel wire, copper wire, aluminum wire, and others. When selecting materials, it is crucial to consider factors such as material composition, specifications, and performance to ensure that the woven stainless steel mesh exhibits excellent performance and appearance quality.

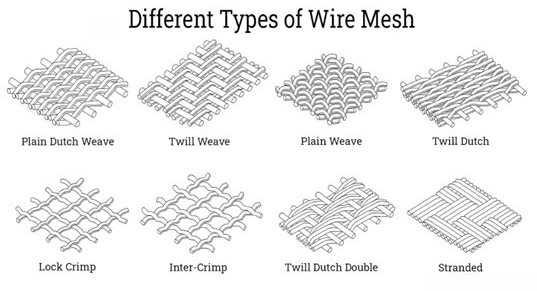

IV. Weaving Techniques

The weaving techniques for Stainless steel wire cloth primarily include plain weave, twill weave, bamboo weave, and contrast weave. When selecting the weaving technique, it is essential to determine the appropriate method based on factors such as the specifications and dimensions of the stainless steel mesh, mesh design, among other considerations.

V. Heat Treatment

After the weaving process, it is necessary to undergo heat treatment to enhance the strength and durability of the SS wire mesh. Heat treatment methods include oil quenching, water quenching, tempering, among others. The selection of the appropriate heat treatment method depends on the specific material and specifications used.

VI. Surface Treatment

To enhance the corrosion resistance and aesthetic appeal of the stainless steel wire mesh, surface treatment is necessary. Surface treatment methods include polishing, galvanizing, powder coating, among others. The selection of the appropriate surface treatment method depends on different usage environments and requirements.

VII. Inspection and Packaging

Following the completion of surface treatment, inspection and packaging are required. Inspection mainly includes dimension checks, visual inspection, performance testing, among others, to ensure that the stainless steel mesh meets the specified requirements. Packaging methods encompass carton packaging, wooden crate packaging, and others, tailored to meet the specific requirements of the customers.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.