Non-Slip Steel Grating Enhancing Safety and Durability

In various industrial and commercial applications, safety is paramount. One critical component that contributes to safety, particularly in walking surfaces, is non-slip steel grating. This specialized material serves not only as a functional flooring solution but also plays a crucial role in preventing accidents caused by slips and falls.

What is Non-Slip Steel Grating?

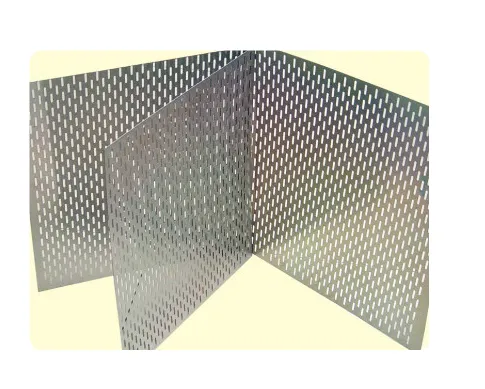

Non-slip steel grating is a type of flooring made from robust steel bars that are processed into a grid pattern. It is designed to maximize strength while minimizing weight. The surface of non-slip steel grating is often treated or designed to ensure a firm grip, thereby reducing the likelihood of slips under various conditions, such as wet or oily environments. The non-slip feature can be achieved through different methods, including serrated edges, raised patterns, or coatings that provide additional traction.

Applications in Various Industries

The applications of non-slip steel grating are vast and varied. It is widely used in industries such as construction, manufacturing, oil and gas, and wastewater treatment. For example, in factories where fluids might spill, non-slip steel grating provides a safe walking surface for workers. In the oil and gas sector, platforms outfitted with this grating ensure the safety of personnel by reducing slip hazards associated with harsh working environments. Additionally, in municipal applications, such as drainage covers and walkways, non-slip steel grating helps enhance pedestrian safety while allowing for efficient water drainage.

Benefits of Non-Slip Steel Grating

non slip steel grating

1. Enhanced Safety The primary benefit of non-slip steel grating is its ability to minimize slips and falls, thereby enhancing overall safety in workplaces. This is particularly important in environments where employees are moving around with heavy equipment or in areas prone to spills.

2. Durability Steel is an incredibly durable material, and when used in grating, it can withstand harsh conditions without degrading. This resilience reduces the need for frequent replacements, making it a cost-effective choice for long-term use.

3. Low Maintenance Unlike other flooring options, non-slip steel grating requires minimal maintenance. Regular cleaning is often sufficient to keep it in good condition, making it a practical option for busy industrial environments where time and maintenance resources may be limited.

4. Versatility Non-slip steel grating can be used in a multitude of applications, from industrial platforms to outdoor walkways. It is customizable in terms of size, shape, and finish, allowing for tailored solutions that meet specific safety needs.

5. Environmentally Friendly Steel is a recyclable material, which adds an environmentally friendly aspect to using steel grating. In a world increasingly focused on sustainability, choosing materials that can be recycled helps reduce the overall environmental impact.

Conclusion

Non-slip steel grating stands as a testament to the importance of safety in industrial and commercial settings. Its design and material properties make it an effective solution for minimizing slip hazards, boosting worker confidence, and enhancing overall operational safety. As industries continue to evolve, the demand for reliable and effective safety solutions like non-slip steel grating will undoubtedly grow. Investing in such solutions is not merely a regulatory requirement but a commitment to the well-being of all personnel involved.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.