Jun . 16, 2024 10:40

Back to list

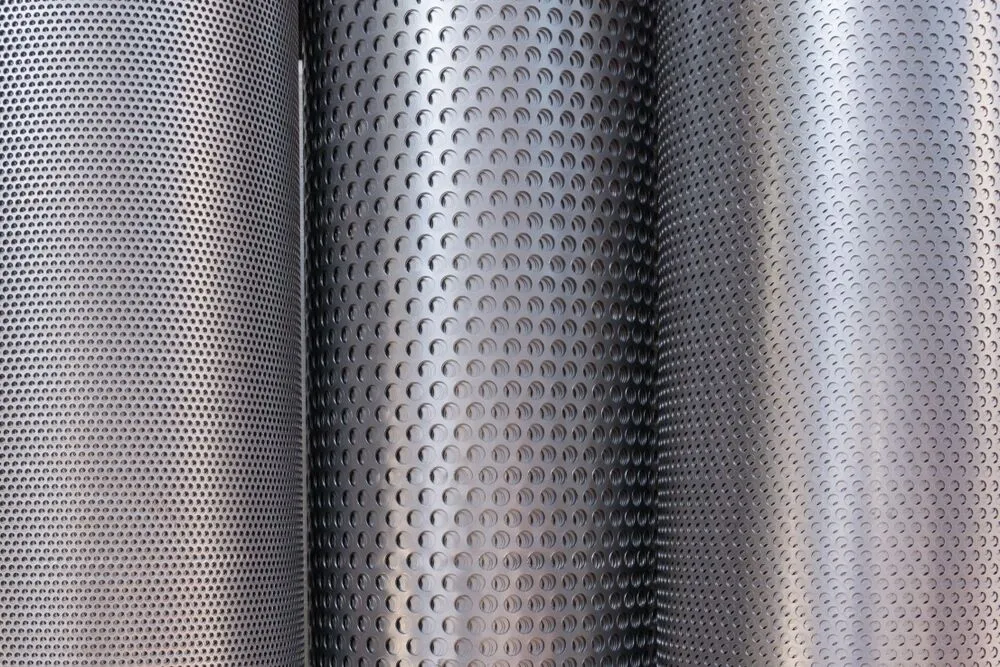

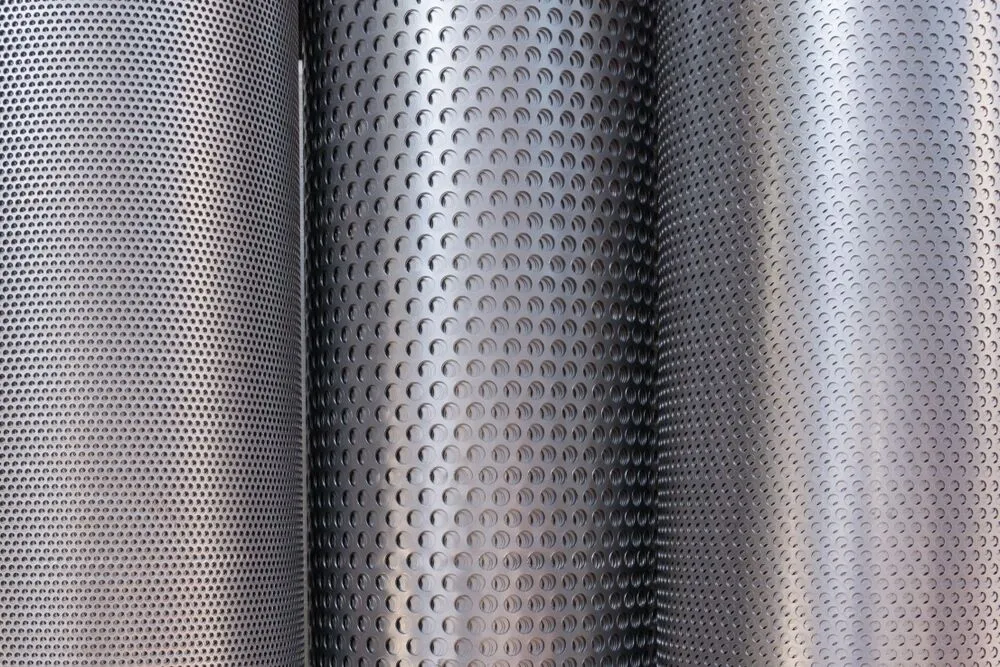

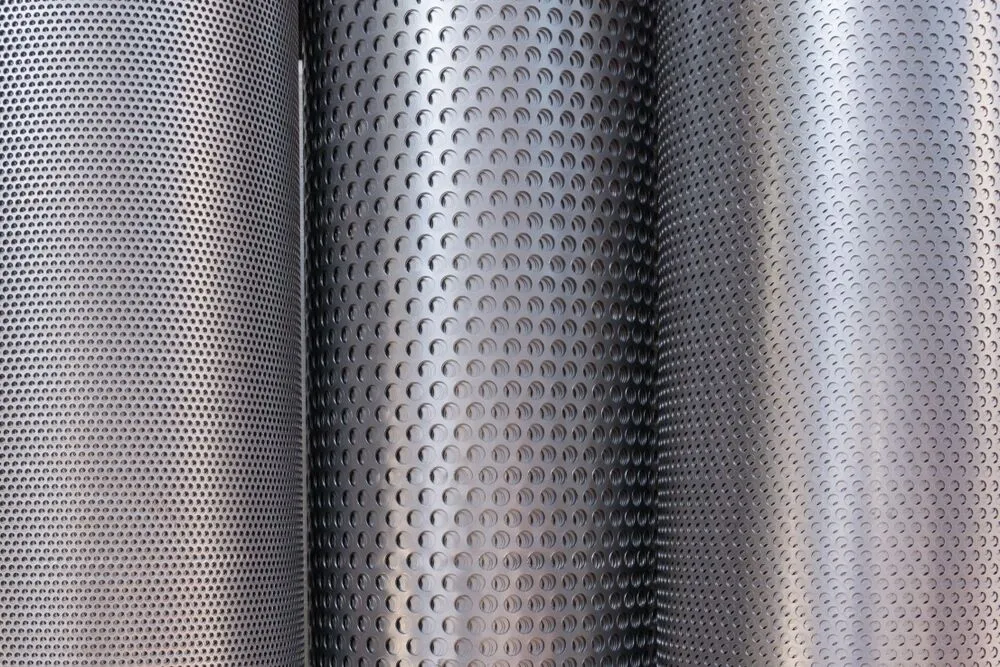

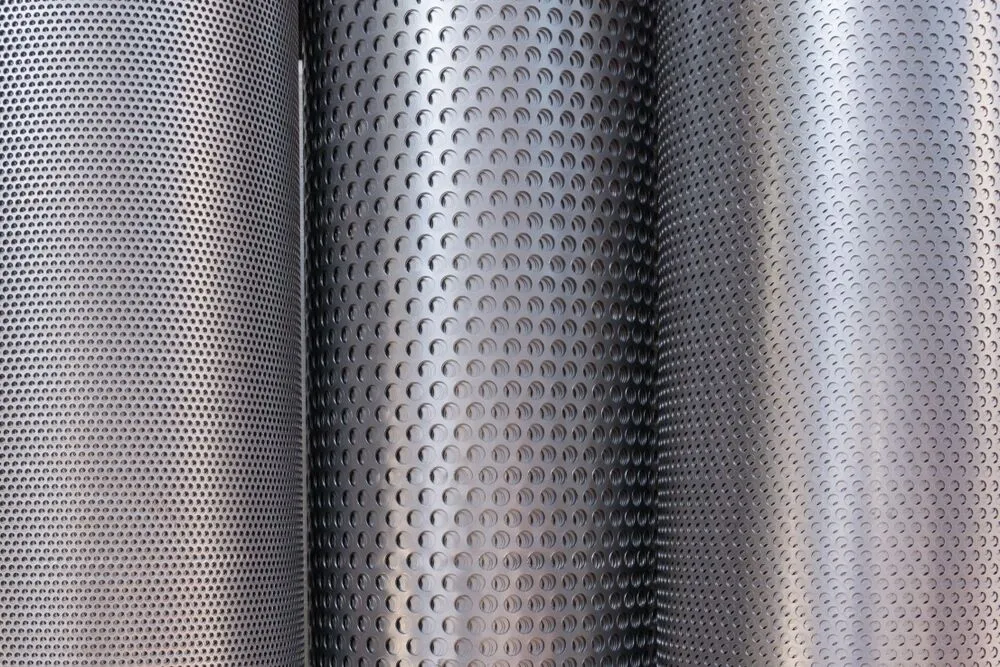

Hexagonal mesh with perforations

Hexagonal Perforated Mesh A Revolution in Industrial Filtration

In the world of industrial filtration, hexagonal perforated mesh has emerged as a game-changer. This innovative design combines the strength of metal with the efficiency of hexagonal patterns, creating a material that is both robust and precise in its filtering capabilities. The unique structure of these meshes offers unparalleled advantages over traditional square or rectangular grid patterns, making them an essential component in various industries ranging from chemical processing to food production.

The hexagonal shape itself is a masterpiece of geometric efficiency. Each cell within the mesh is a perfect hexagon, tightly packed together to form a honeycomb-like structure. This configuration allows for maximum open area relative to the amount of material used, which translates to greater flow rates and reduced pressure drops across the filter. Moreover, the consistent and repeating pattern ensures that particles of specific sizes are consistently filtered out, ensuring high-quality end products.

Perforations in the hexagonal mesh are precisely engineered to meet diverse filtration needs. Whether tiny apertures are required for intricate chemical separations or larger holes for coarser screenings in food processing, these meshes can be tailored to exact specifications. The manufacturing process ensures that each hole maintains its shape and size under stress and corrosive environments, guaranteeing longevity and reliable performance.

One of the notable benefits of hexagonal perforated mesh is its enhanced strength-to-weight ratio. The hexagon's inherent structural stability means that less material can be used to achieve the same level of durability as compared to other shapes. This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes

This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes hexagonal perforated mesh.

In applications where cleanliness is paramount, such as in the pharmaceutical industry, hexagonal perforated mesh stands out due to its smooth surface and lack of crevices where contaminants could hide. Cleaning becomes far more manageable, and sterilization processes are more effective, ensuring compliance with stringent sanitation standards.

The adaptability of hexagonal perforated mesh is further highlighted by its compatibility with automated systems. In modern facilities, integration with machines that require precise control over filtration can be seamlessly achieved thanks to the uniformity and predictability of the mesh's design. This feature enables consistent output and reduces the possibility of errors that could compromise product quality or production efficiency.

Manufacturers are continuously exploring new materials and coatings to enhance the properties of hexagonal perforated mesh. Corrosion-resistant alloys, polymer coatings, and specialized fibers are being utilized to expand the mesh's applicability in harsher environments. As research progresses, we can expect these meshes to play an even greater role in advanced filtration technologies, pushing the boundaries of what is possible in separating and refining substances across various sectors.

In conclusion, the advent of hexagonal perforated mesh represents a significant advancement in industrial filtration technology. Its optimal geometry, customizable features, and structural efficiency make it an indispensable tool for maintaining product purity and process efficiency. As industry demands continue to evolve, so too will the development of this remarkable filtering solution, ensuring that it remains at the forefront of filtration innovation.

hexagonal perforated mesh.

In applications where cleanliness is paramount, such as in the pharmaceutical industry, hexagonal perforated mesh stands out due to its smooth surface and lack of crevices where contaminants could hide. Cleaning becomes far more manageable, and sterilization processes are more effective, ensuring compliance with stringent sanitation standards.

The adaptability of hexagonal perforated mesh is further highlighted by its compatibility with automated systems. In modern facilities, integration with machines that require precise control over filtration can be seamlessly achieved thanks to the uniformity and predictability of the mesh's design. This feature enables consistent output and reduces the possibility of errors that could compromise product quality or production efficiency.

Manufacturers are continuously exploring new materials and coatings to enhance the properties of hexagonal perforated mesh. Corrosion-resistant alloys, polymer coatings, and specialized fibers are being utilized to expand the mesh's applicability in harsher environments. As research progresses, we can expect these meshes to play an even greater role in advanced filtration technologies, pushing the boundaries of what is possible in separating and refining substances across various sectors.

In conclusion, the advent of hexagonal perforated mesh represents a significant advancement in industrial filtration technology. Its optimal geometry, customizable features, and structural efficiency make it an indispensable tool for maintaining product purity and process efficiency. As industry demands continue to evolve, so too will the development of this remarkable filtering solution, ensuring that it remains at the forefront of filtration innovation.

This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes

This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes This characteristic not only reduces material costs but also makes the mesh easier to handle during installation and replacement processes hexagonal perforated mesh.

In applications where cleanliness is paramount, such as in the pharmaceutical industry, hexagonal perforated mesh stands out due to its smooth surface and lack of crevices where contaminants could hide. Cleaning becomes far more manageable, and sterilization processes are more effective, ensuring compliance with stringent sanitation standards.

The adaptability of hexagonal perforated mesh is further highlighted by its compatibility with automated systems. In modern facilities, integration with machines that require precise control over filtration can be seamlessly achieved thanks to the uniformity and predictability of the mesh's design. This feature enables consistent output and reduces the possibility of errors that could compromise product quality or production efficiency.

Manufacturers are continuously exploring new materials and coatings to enhance the properties of hexagonal perforated mesh. Corrosion-resistant alloys, polymer coatings, and specialized fibers are being utilized to expand the mesh's applicability in harsher environments. As research progresses, we can expect these meshes to play an even greater role in advanced filtration technologies, pushing the boundaries of what is possible in separating and refining substances across various sectors.

In conclusion, the advent of hexagonal perforated mesh represents a significant advancement in industrial filtration technology. Its optimal geometry, customizable features, and structural efficiency make it an indispensable tool for maintaining product purity and process efficiency. As industry demands continue to evolve, so too will the development of this remarkable filtering solution, ensuring that it remains at the forefront of filtration innovation.

hexagonal perforated mesh.

In applications where cleanliness is paramount, such as in the pharmaceutical industry, hexagonal perforated mesh stands out due to its smooth surface and lack of crevices where contaminants could hide. Cleaning becomes far more manageable, and sterilization processes are more effective, ensuring compliance with stringent sanitation standards.

The adaptability of hexagonal perforated mesh is further highlighted by its compatibility with automated systems. In modern facilities, integration with machines that require precise control over filtration can be seamlessly achieved thanks to the uniformity and predictability of the mesh's design. This feature enables consistent output and reduces the possibility of errors that could compromise product quality or production efficiency.

Manufacturers are continuously exploring new materials and coatings to enhance the properties of hexagonal perforated mesh. Corrosion-resistant alloys, polymer coatings, and specialized fibers are being utilized to expand the mesh's applicability in harsher environments. As research progresses, we can expect these meshes to play an even greater role in advanced filtration technologies, pushing the boundaries of what is possible in separating and refining substances across various sectors.

In conclusion, the advent of hexagonal perforated mesh represents a significant advancement in industrial filtration technology. Its optimal geometry, customizable features, and structural efficiency make it an indispensable tool for maintaining product purity and process efficiency. As industry demands continue to evolve, so too will the development of this remarkable filtering solution, ensuring that it remains at the forefront of filtration innovation. Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP