Jan . 13, 2025 17:01

Back to list

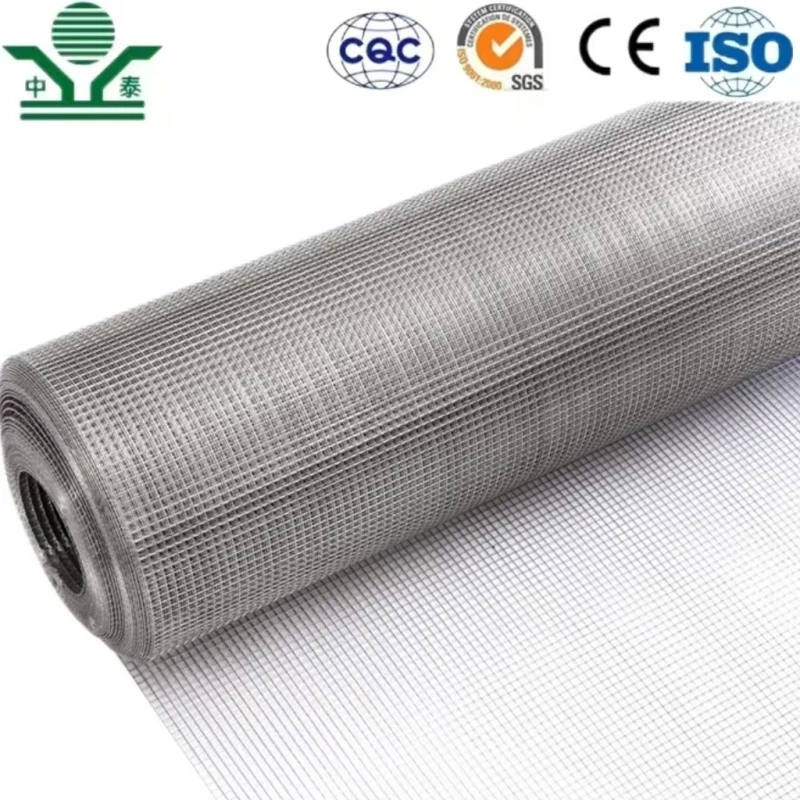

Heavy expanded metal mesh

Expanded steel mesh, an innovative material frequently employed in construction, manufacturing, and design, offers a myriad of advantages that make it a versatile choice for various projects. Its unique structure, created by simultaneously slitting and stretching a steel sheet, results in an interconnected pattern of uniform diamond-shaped openings. This distinctive formation not only enhances its strength-to-weight ratio but also provides an array of practical applications that cater to different industry needs.

Importantly, the application of expanded steel mesh is backed by a foundation of expertise and industry standards, ensuring its reliability and safety. Manufacturers typically adhere to rigorous quality controls, including compliance with ASTM standards, to guarantee the mesh's integrity and uniformity. Such standardization reinforces the material’s credibility in demanding applications, supporting its authoritative position in the industry. Moreover, the sustainability factor associated with expanded steel mesh cannot be overlooked. The production process, which involves the mechanical expansion of steel, typically results in minimal waste compared to other manufacturing methods. The material’s durability also means it has a long life cycle, reducing the need for frequent replacements and minimizing environmental impacts. For professionals in construction, manufacturing, and design, understanding and applying expanded steel mesh effectively can enhance the quality and innovation of their projects. By prioritizing experience, expertise, authoritativeness, and trustworthiness, stakeholders can ensure that they harness the full potential of this dynamic material. It stands as a testament to the progress and ingenuity within materials engineering, offering solutions that meet modern demands for strength, efficiency, and aesthetic appeal.

Importantly, the application of expanded steel mesh is backed by a foundation of expertise and industry standards, ensuring its reliability and safety. Manufacturers typically adhere to rigorous quality controls, including compliance with ASTM standards, to guarantee the mesh's integrity and uniformity. Such standardization reinforces the material’s credibility in demanding applications, supporting its authoritative position in the industry. Moreover, the sustainability factor associated with expanded steel mesh cannot be overlooked. The production process, which involves the mechanical expansion of steel, typically results in minimal waste compared to other manufacturing methods. The material’s durability also means it has a long life cycle, reducing the need for frequent replacements and minimizing environmental impacts. For professionals in construction, manufacturing, and design, understanding and applying expanded steel mesh effectively can enhance the quality and innovation of their projects. By prioritizing experience, expertise, authoritativeness, and trustworthiness, stakeholders can ensure that they harness the full potential of this dynamic material. It stands as a testament to the progress and ingenuity within materials engineering, offering solutions that meet modern demands for strength, efficiency, and aesthetic appeal.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP