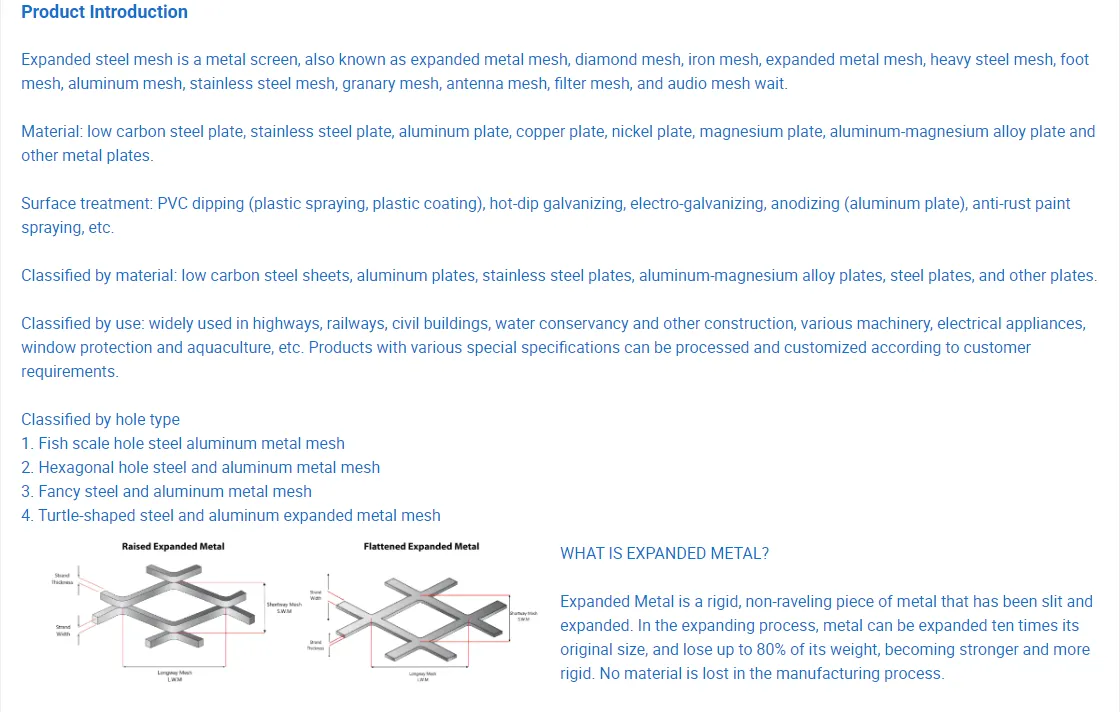

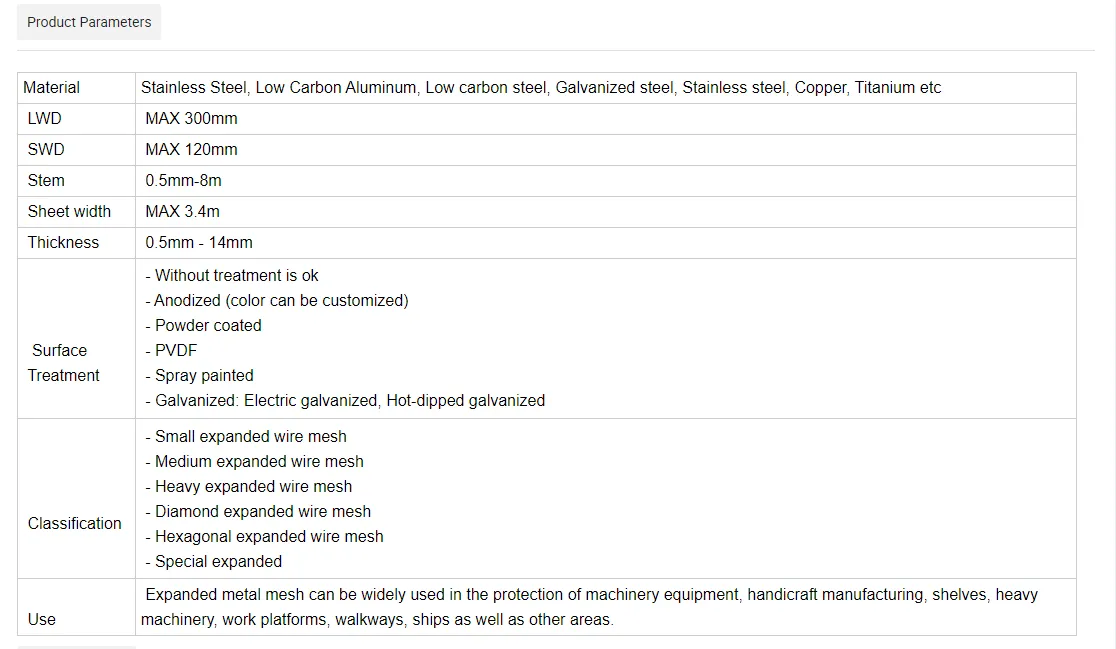

Product Description

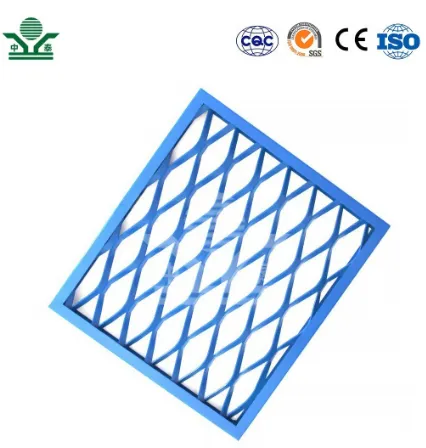

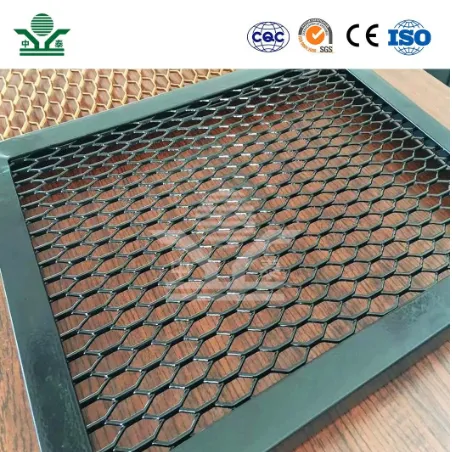

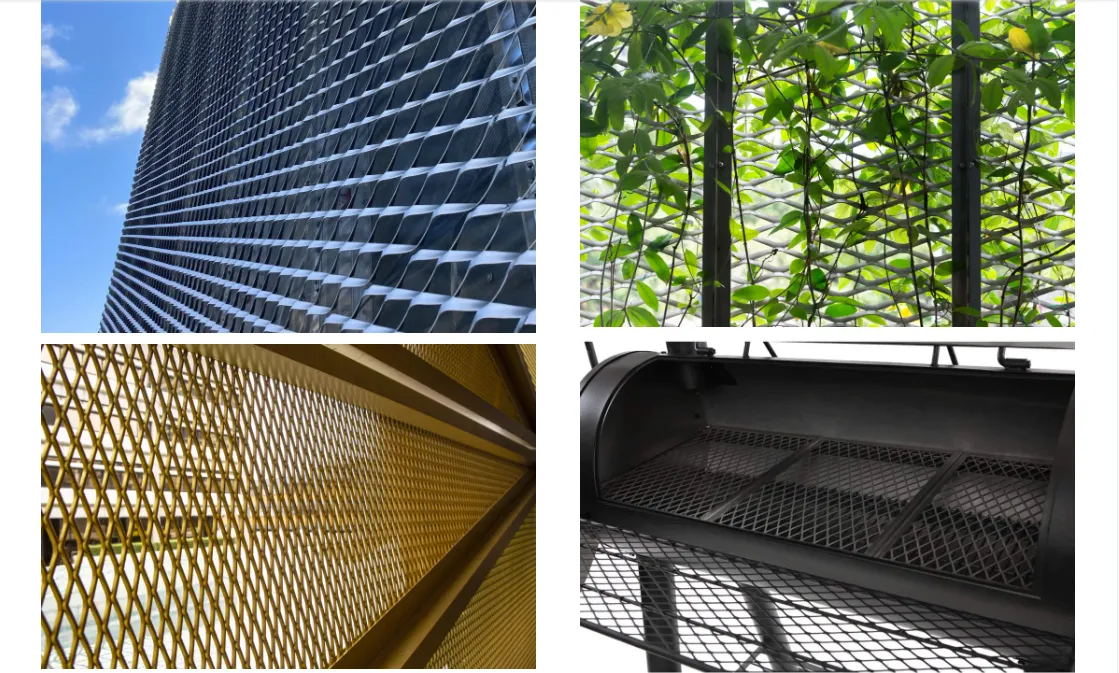

ZHONGTAI Pure Copper Sheet Plate Material Aluminium Diamond Mesh Sheet China Factory Diamond Hole Shape Expanded Metal Sheet Mesh

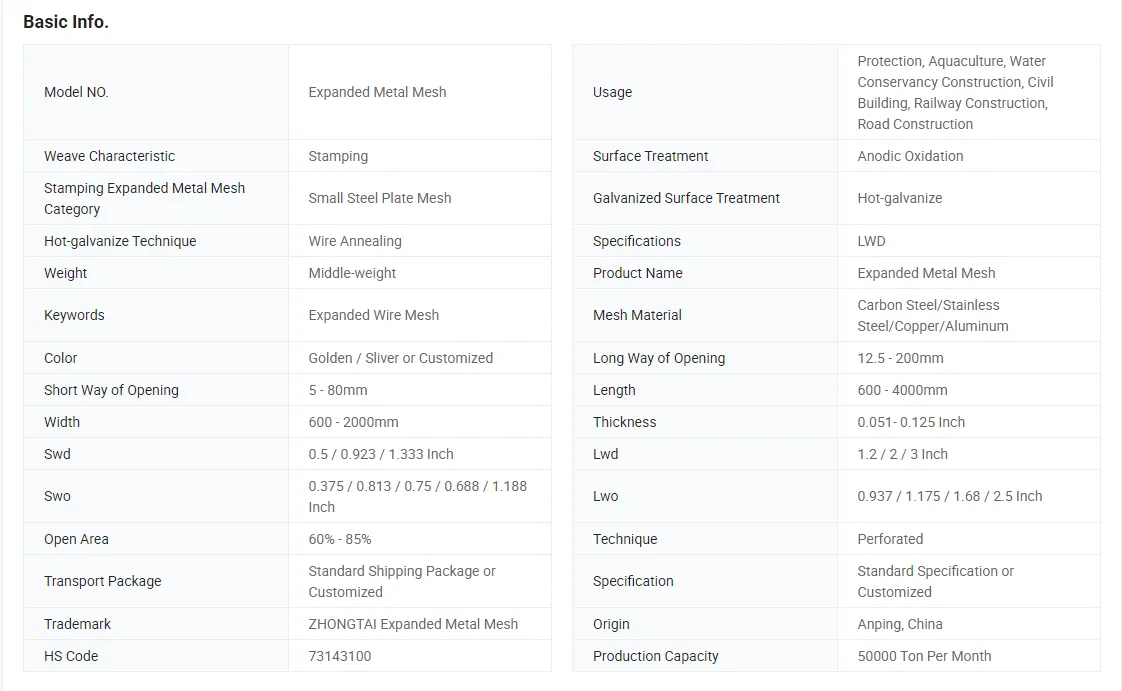

EXPANDED METAL CHARACTERISTICS

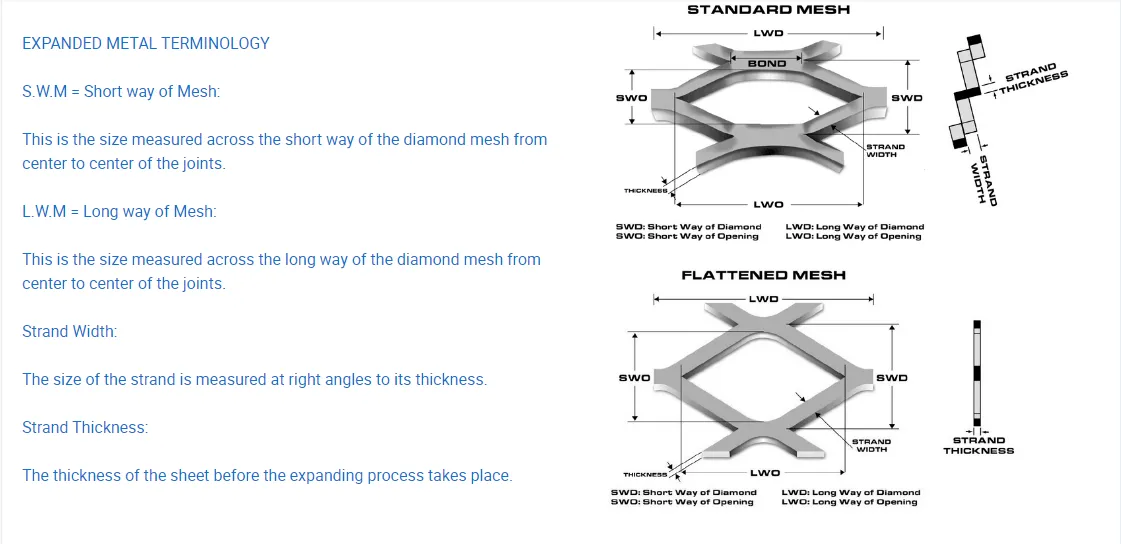

There are two types of expanded metal.

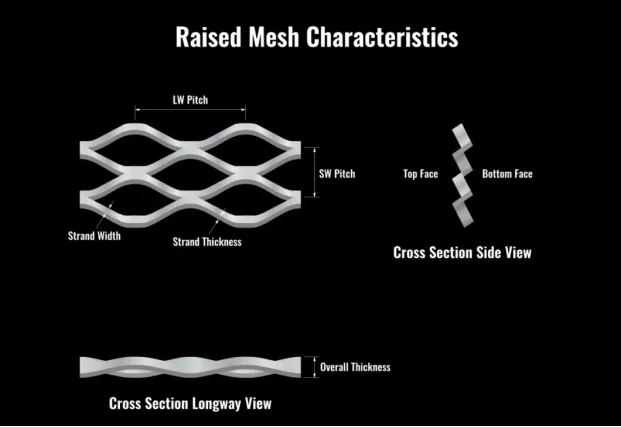

Raised mesh is unchanged from the expanding process where the individual strands are set at an angle to the plane of the sheet which results in a superior strength-to-weight ratio, enhanced sheet rigidity, good anti-slip properties, and an increase in overall thickness of the original raw material sheet due to the angled strands.

Raised mesh is measured from the center of one mesh to the center of the adjacent mesh, this is referred to as the LW and SW Pitch as shown below.

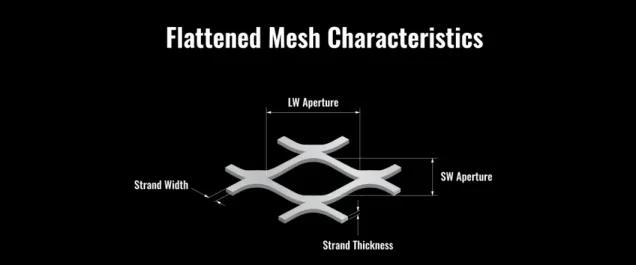

Flattened mesh is simply a raised mesh that is passed through heavy-duty pressurized metal rolls to create a mesh with a flat surface to the sheet. Flattened mesh is generally processed to the same thickness as the original raw material or just below that base thickness. Flattened mesh is desirable where a lower overall thickness is desirable or if a flat surface is required to have greater surface area for example, when welding into a frame.

Flattened mesh is measured from the internal opening of the diamond, this is referred to as the LW and SW Aperture as shown below.

Walkway mesh is described in the same manner as raised mesh.

Flattened mesh is simply a raised mesh that is passed through heavy-duty pressurized metal rolls to create a mesh with a flat surface to the sheet. Flattened mesh is generally processed to the same thickness as the original raw material or just below that base thickness. Flattened mesh is desirable where a lower overall thickness is desirable or if a flat surface is required to have greater surface area for example, when welding into a frame.

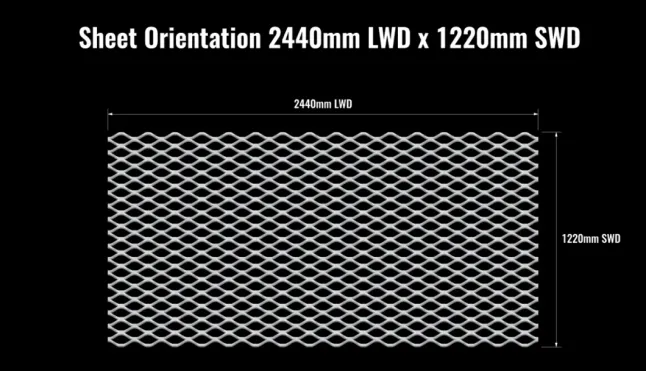

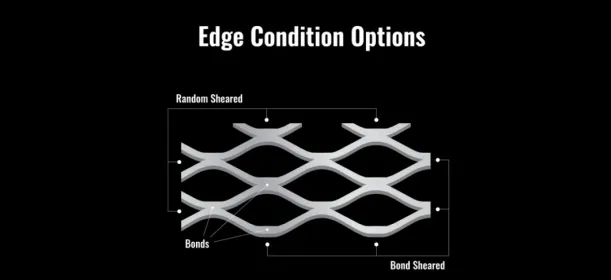

SHEET SIZE AND MESH ORIENTATION

Expanded metal is available in a wide variety of sheet sizes. The items shown on our website are a guide to the standard items we manufacture as standard stock items.

The sheet size is described as LWD and SWD (LW and SW Dimension). The standard sheet sizes are 2440mm LWD x 1220mm SWD and 1250mm LWD x 2500mm SWD as illustrated here.

Stock sheets are manufactured to a nominal plus tolerance and are likely to be delivered slightly oversized. If exact sizes are required we recommend this be discussed at the time of order.

It is possible to produce other sizes, please contact us for more details.

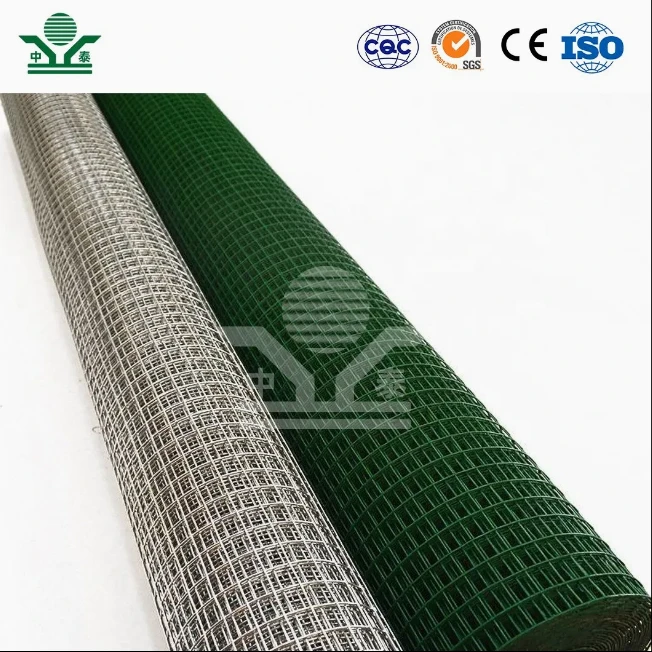

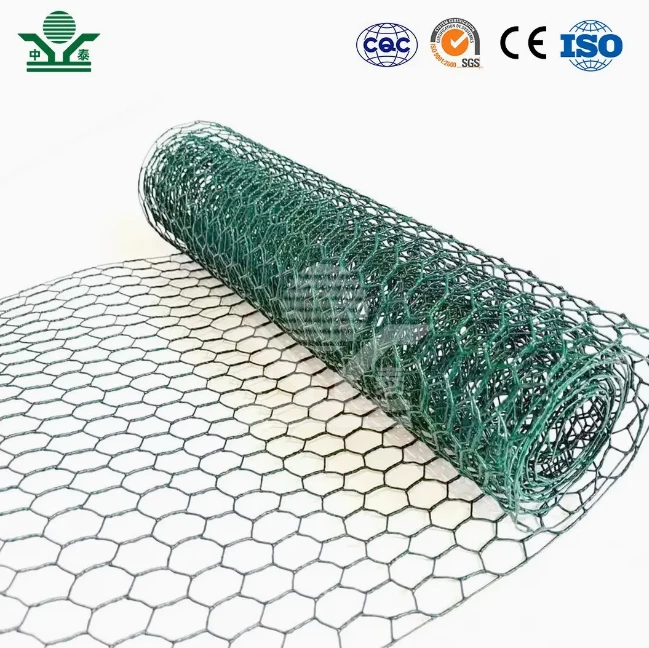

CUSTOM-MADE PRODUCTS & CUT TO-SIZE ITEMS

We offer a custom manufacturing service where bespoke specifications and sheet sizes can be made to suit your individual needs. This may be a variation to the mesh specification to enhance its performance or to ship the material to you in cut-to-size panels or large format sheets.

All our meshes are capable of being supplied in a cut-to-size finish, the majority being cut in-house on our guillotines. 6mm thick walkway mesh (12-99WR) and certain designer meshes cannot be cut on a conventional metal guillotine so would require cutting by a sub-contract water jet cutting service. Please ask for more details.

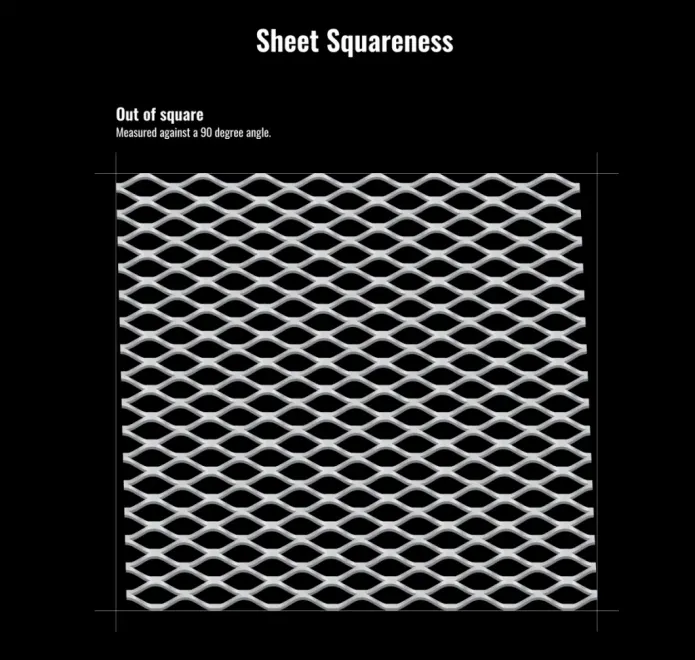

The benefit of sheared panels is not only dimensional accuracy and close tolerances but the shearing process ensures sheet squareness.

Expanded Metal which is machine run is not guaranteed to be perfectly square. The only way of creating sheets that are reliably square is to cut them after expanding. The illustration below shows how 'stock' mesh can be out of square, cutting to size is a reliable and quick way of overcoming this.

It is possible to introduce production controls for certain products at the planning stage to overcome the issue of squareness. Certain designer products can be machine-run with very tight squareness and dimensional tolerances so please talk to us to discuss the specific needs of your project.

Q1. What Are Your Terms Of Packing?

A: Generally, We Pack Our Goods In Neutral White Boxes And Brown Cartons. If You Have A Legally Registered Patent,

We Can Pack The Goods In Your Branded Boxes After Getting Your Authorization Letters.

Q2. How About Your Delivery Time?

A: Generally, It Will Take 15 To 30 Days After Receiving Your Advance Payment. The Specific Delivery Time Depends

On The Items And The Quantity Of Your Order.

Q3. Can You Produce According To The Samples?

A: Yes, We Can Produce Your Samples Or Technical Drawings. We Can Build The Molds And Fixtures.

Q4. What Is Your Sample Policy?

A: We Can Supply The Sample If We Have Ready Parts In Stock, But The Customers Have To Pay The Sample Cost And

The Courier Cost.

Q5. Do You Test All Your Goods Before Delivery?

A: Yes, We Have 100% Test Before Delivery

Q6: How Do You Make Our Business Long-Term And Good Relationship?

A:1. We Keep Good Quality And Competitive Prices To Ensure Our Customers Benefit ;

2. We Respect Every Customer As Our Friend And We Sincerely Do Business And Make Friends With Them,

No Matter Where They Come From.