Heavy Duty Mild Steel Grating A Comprehensive Overview

Heavy-duty mild steel grating is a versatile and robust material widely employed in various industrial applications due to its strength, resilience, and cost-effectiveness. Grating is primarily used for flooring, walkways, platforms, and drainage covers, providing safe and durable surfaces in high-traffic areas. This article delves into the characteristics, advantages, applications, and maintenance of heavy-duty mild steel grating.

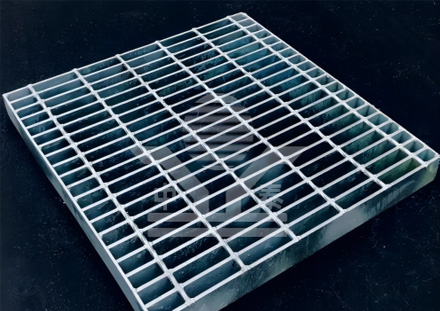

Characteristics of Heavy Duty Mild Steel Grating

Heavy-duty mild steel grating is characterized by its thick, strong bars that provide enhanced load-bearing capabilities. Typically produced from high-quality mild steel, it features a variety of patterns and designs, promoting safety and stability. Standard specifications include load capacities that can withstand heavy weights, making it suitable for industrial environments. The grating often features different treatments such as hot-dip galvanization or powder coating to enhance corrosion resistance and longevity.

Mild steel, an alloy of iron and carbon, has significant structural integrity and is relatively easy to fabricate. This material can be manufactured in various thicknesses and diameters, allowing for customization to meet specific project requirements. The open design of steel grating promotes air circulation, light penetration, and drainage, minimizing the risk of slip and preventing the accumulation of debris.

Advantages of Heavy Duty Mild Steel Grating

One of the primary advantages of heavy-duty mild steel grating is its strength and durability. It can bear considerable loads, making it ideal for heavy machinery and equipment applications. Additionally, mild steel is relatively cost-effective compared to other materials such as stainless steel or aluminum, providing a practical solution for budget-conscious projects.

The maintenance of steel grating is generally simple, requiring routine inspections to check for signs of wear or corrosion. When treated appropriately, heavy-duty mild steel grating can have a long lifespan, minimizing the need for frequent replacements.

heavy duty mild steel grating

Another significant advantage is the ease of installation. Steel grating can be quickly and efficiently installed, which is especially beneficial for large projects that need to adhere to tight deadlines. The lightweight nature of grating panels also contributes to more manageable handling and transport.

Applications of Heavy Duty Mild Steel Grating

Heavy-duty mild steel grating is utilized in numerous sectors, including manufacturing, construction, oil and gas, mining, and transportation. In industrial settings, it is often found in platforms, stairways, and walkways, where high foot or vehicle traffic is expected. It is also employed extensively in wastewater treatment facilities, chemical processing plants, and power generation stations, due to its ability to withstand harsh environmental conditions.

In construction, mild steel grating is used for safety covers over trenches, drains, and pits, ensuring worker safety while maintaining site accessibility. Additionally, it is commonly utilized in commercial settings, including shopping malls and public buildings, for creating aesthetically pleasing and functional walkways.

Maintenance and Care

Maintaining heavy-duty mild steel grating is integral to ensuring its longevity and effectiveness. Regular cleaning helps prevent the buildup of debris and can reduce the risk of corrosion. Any signs of damage, particularly in areas subjected to heavy loads, should be addressed promptly to prevent further deterioration. Reapplications of protective coatings can extend the life of steel grating significantly.

In conclusion, heavy-duty mild steel grating is an essential component in various applications due to its strength, durability, and cost-effectiveness. With the proper maintenance and care, this material can serve multiple purposes in industrial and commercial environments, making it a smart choice for those seeking reliable and robust flooring solutions.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.