The Versatility of Thin Perforated Metal Sheets

Thin perforated metal sheets have emerged as an essential material across various industries, owing to their unique properties and aesthetic appeal. These sheets, characterized by their patterns of holes, slots, or other geometrical shapes, combine the strengths of metal with the functionality of perforation. As we delve into the world of thin perforated metal sheets, we will explore their manufacturing process, applications, benefits, and trends shaping their future.

Manufacturing Process

The production of thin perforated metal sheets begins with selecting the appropriate metal, typically aluminum, stainless steel, or mild steel. The choice of material depends on various factors, including the intended application, desired aesthetic, and environmental considerations. Once the metal is chosen, it is fed into a perforating machine that applies pressure through a die, creating precise holes in the desired pattern. After perforation, the sheets undergo finishing processes such as cleaning, coating, or punching edge treatments to enhance durability and appearance. This process allows for a vast range of hole shapes and sizes, providing designers with the flexibility needed for both functional and decorative uses.

Applications

Thin perforated metal sheets find their place in numerous applications. In architecture and design, they are used for facades, sunshades, and interior panels, allowing light while providing privacy and ventilation. In industrial settings, they serve as filters and separators, facilitating airflow and noise reduction in machinery and equipment. Additionally, the automotive industry employs perforated sheets in grilles, bumpers, and sound-dampening components, enhancing both function and style.

Another notable application is in the construction of furniture and fixtures. Perforated metal sheets can create visually striking tables, chairs, and shelves while ensuring structural integrity. Moreover, many artists and designers appreciate the aesthetic qualities of these sheets, incorporating them into innovative art installations and contemporary designs.

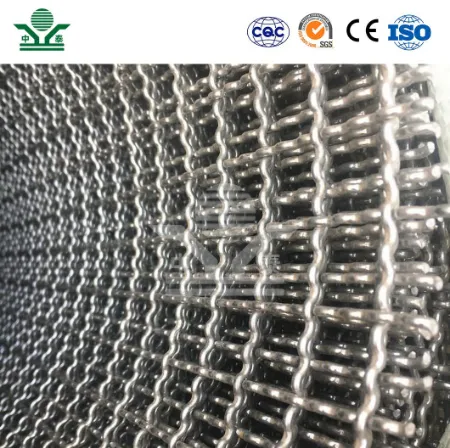

thin perforated metal sheet

Benefits

The advantages of using thin perforated metal sheets are manifold. First and foremost, their lightweight nature makes them easier to handle and install compared to solid metal sheets, reducing transportation and labor costs. Their durability ensures a long lifespan, even in harsh environments, while their versatility allows for combinations of perforation patterns and materials tailored to specific needs.

Furthermore, thin perforated metal sheets contribute to energy efficiency as they often allow for natural light and airflow, reducing reliance on artificial lighting and ventilation systems. This capability not only enhances comfort but also aligns with sustainable building practices, which are increasingly prioritized in architecture and construction.

Trends and Future Directions

As industries evolve, so do the applications and technologies associated with thin perforated metal sheets. The rise of digital fabrication techniques has opened new avenues for customization, enabling designers to create intricate patterns that were previously challenging to achieve. Moreover, advancements in coatings and finishes, such as anti-corrosion treatments and eco-friendly options, are helping to enhance the performance and sustainability of these sheets.

Another trend is the growing demand for sustainable and recycled materials in construction and manufacturing. Thin perforated metal sheets, often produced from recyclable metals, align well with this shift, making them a preferred choice in green building initiatives.

In conclusion, thin perforated metal sheets are not just functional materials but also a canvas for creativity and innovation. Their diverse applications, coupled with the numerous benefits they offer, position them as a vital component in various industries. As technology continues to advance and sustainability becomes increasingly important, the future of thin perforated metal sheets looks promising, ensuring that they remain a staple in both practical applications and artistic endeavors alike.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.