Jan . 14, 2025 10:07

Back to list

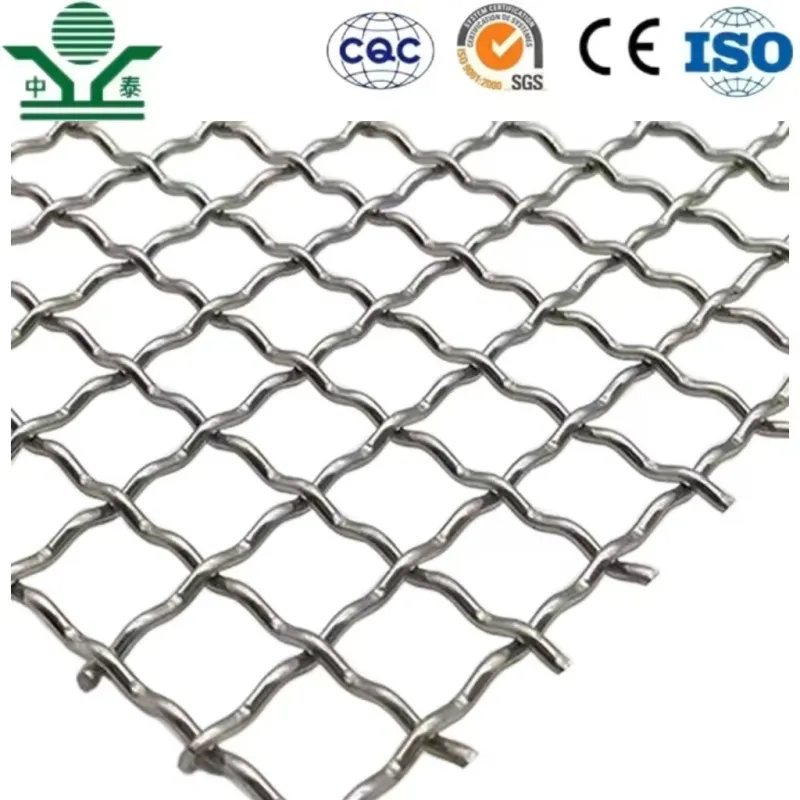

heavy duty expanded steel mesh

Heavy duty expanded steel mesh stands as a pillar of innovation in the construction and industrial sectors. Boasting an impressive blend of strength, durability, and versatility, this material has carved out a niche for itself across various applications. It is crucial to explore the aspects that contribute to its reputation, as its adoption continues to increase in projects worldwide.

Experts in materials engineering recognize expanded steel mesh's unique characteristics which enable it to adapt to various customizations. Its flexibility in terms of thickness, strand width, and aperture sizes allow it to meet the specific requirements of diverse projects. Hence, professionals selecting this material are not only leveraging its inherent strengths but also tailoring it to optimize performance for their particular applications. Despite its advantages, selecting the appropriate type and grade of expanded steel mesh requires a nuanced understanding of one’s project needs. Working closely with certified suppliers or consulting with engineers specializing in material sciences can ensure the selection meets project specifications without compromising on quality. Trust in expanded steel mesh is strengthened by rigorous testing and adherence to standards set by industry authorities. Professional bodies and manufacturers provide certifications to confirm the material's conformance to safety and quality benchmarks, thereby enhancing its credibility and fostering trust among users and stakeholders. In conclusion, heavy duty expanded steel mesh stands out due to its unparalleled combination of strength, adaptability, and eco-friendly production. It has proven itself indispensable in both construction and industrial applications, where dependability and efficiency are paramount. Consulting with experts and relying on certified suppliers ensures that projects not only benefit from the mesh’s myriad advantages but also align with the highest standards of safety and performance.

Experts in materials engineering recognize expanded steel mesh's unique characteristics which enable it to adapt to various customizations. Its flexibility in terms of thickness, strand width, and aperture sizes allow it to meet the specific requirements of diverse projects. Hence, professionals selecting this material are not only leveraging its inherent strengths but also tailoring it to optimize performance for their particular applications. Despite its advantages, selecting the appropriate type and grade of expanded steel mesh requires a nuanced understanding of one’s project needs. Working closely with certified suppliers or consulting with engineers specializing in material sciences can ensure the selection meets project specifications without compromising on quality. Trust in expanded steel mesh is strengthened by rigorous testing and adherence to standards set by industry authorities. Professional bodies and manufacturers provide certifications to confirm the material's conformance to safety and quality benchmarks, thereby enhancing its credibility and fostering trust among users and stakeholders. In conclusion, heavy duty expanded steel mesh stands out due to its unparalleled combination of strength, adaptability, and eco-friendly production. It has proven itself indispensable in both construction and industrial applications, where dependability and efficiency are paramount. Consulting with experts and relying on certified suppliers ensures that projects not only benefit from the mesh’s myriad advantages but also align with the highest standards of safety and performance.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP