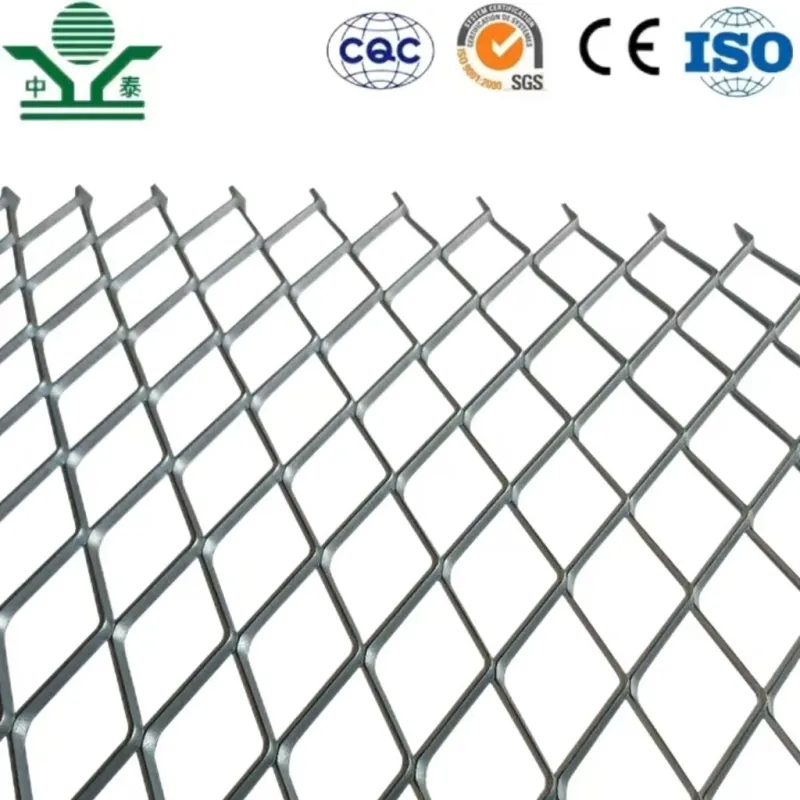

Good Quality Diamond Hole Galvanized Low Carbon Steel Expanded Metal Mesh: field notes from the factory floor

When specifiers ask me for a dependable, no-drama mesh for facades, walkways, and guards, I usually point them to Good Quality Diamond Hole Galvanized Low Carbon Steel Expanded Metal Mesh. It’s made in Anping—the historic wire-mesh hub in Hebei, China (No. 12, Jingwu Road, East District, Industrial Park). The short version: consistent openings, honest zinc, and better value than perforated plate in many jobs. The longer version is below.

What’s trending (and why it matters)

The market is drifting toward lighter yet tougher cladding and safety flooring. Expanded metal fits that curve: no scrap from punching, less weight than solid sheet, and—surprisingly—more rigidity than people expect because of the strand geometry. Architects are leaning into diamond and scale holes for light-play; plant managers, meanwhile, care about slip resistance and maintenance cycles. To be honest, both win.

Technical overview & process flow

Material options include low carbon steel (most common), stainless steel, aluminum, brass, titanium, nickel, and Al‑Mg alloy. The line slits and expands in one pass (no welding), then sheets are either left “raised” or flattened. Surface treatment: untreatment, pre‑galvanized, or hot‑dip galvanized after expanding. Galvanizing follows ISO 1461/ASTM A123 practices for after-fabrication; some batches use electro‑galvanizing for thinner deposits where budget or conductivity is key.

QC checkpoints: aperture (SWD/LWD) tolerance, strand width/thickness, flatness, zinc coating thickness via magnetic gauge, and adhesion. Typical service life is ≈10–25 years outdoors depending on local corrosion category (C2–C4); coastal or chemical sites may need thicker zinc or stainless. Testing references used in audits: ASTM E2016 (expanded metal), ASTM A123 or ISO 1461 (HDG), and salt spray per ASTM B117.

Indicative specifications (common picks)

| Parameter | Typical Value | Notes |

|---|---|---|

| Hole shape | Diamond (standard), Square, Scale | Diamond chosen for strength-to-weight |

| SWD × LWD | 25 × 50 mm, 30 × 60 mm, 45 × 100 mm | Other sizes on request (≈±0.5–1.5 mm) |

| Thickness / Strand | 1.5–4.0 mm / 1.8–5.0 mm | Raised or flattened finish |

| Sheet size | 1.0 × 2.0 m, 1.22 × 2.44 m, custom | Panels cut to fit frames |

| Coating (HDG) | ≈70–120 μm (Zinc) | ASTM A123/ISO 1461; real-world may vary |

Where it’s used (and why)

- Industrial walkways, platforms, and machine guards (great anti-slip).

- Architectural facades, sunscreens, room dividers—nice shadows, easy airflow.

- Fencing, security screens, ventilation grilles, filter pre-screens, acoustic wraps.

Many customers say maintenance is low; dust doesn’t cake like it does on perforated.

Two quick case notes

1) Coastal facade, Southeast Asia: Good Quality Diamond Hole Galvanized Low Carbon Steel Expanded Metal Mesh, HDG ≈90 μm, plus clear seal—salt spray lab test >480 h (ASTM B117). After 3 years, only minor patina. 2) Petrochemical walkway, Middle East: raised diamond, 3.0 mm thick; operators liked the grip and the lighter dead load on old frames. No weld failures—because, well, there are no welds.

Customization & options

Cut-to-size, framed panels, powder topcoat over galvanizing, radius bending, slotting for anchors, and bespoke SWD/LWD ratios for specific airflow or privacy. If you need stainless or aluminum for aggressive atmospheres, that’s doable. I guess it comes down to budget vs. lifespan.

Vendor snapshot (informal comparison)

| Criteria | ZT Wire Mesh (Anping) | Vendor B | Vendor C |

|---|---|---|---|

| Certifications | ISO 9001; SGS inspection | ISO 9001 | — |

| Galvanizing | HDG to ASTM A123/ISO 1461 | Electro‑galv (thin) | Mixed |

| MOQ & lead time | Low MOQ; ≈10–15 days | Medium; ≈20–30 days | Varies |

| Documentation | Mill certs, Zn thickness logs | Basic COA | Limited |

Advantages in the field

- Strength-to-weight is excellent; no welds to crack.

- Ventilation and light—without sacrificing guard strength.

- Economical vs. perforated in many gauges; less scrap.

- Galvanized life cycle costs are predictable, which finance teams appreciate.

If you need submittals, ask for coating thickness data, salt-spray results, and load tables for your chosen SWD/LWD. With Good Quality Diamond Hole Galvanized Low Carbon Steel Expanded Metal Mesh, the paperwork is usually as tidy as the product—rare, but it happens.

Authoritative references

- ASTM A123/A123M – Standard Specification for Zinc (Hot‑Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods.

- ASTM E2016 – Standard Specification for Industrial Wire Cloth and Screens (Expanded Metal section).

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

-

Comprehensive Guide to Trench Gratings: Design, Applications & Innovations

NewsNov.21,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.