perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes is a key solution in the manufacturing industry, specifically within Fabricated metal products and Punching mesh and perforated plate manufacturing. This article explores how AnPing Zhongtai Expanded Metal Mesh Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes Overview

- Benefits & Use Cases of perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes in Punching mesh and perforated plate manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes Overview

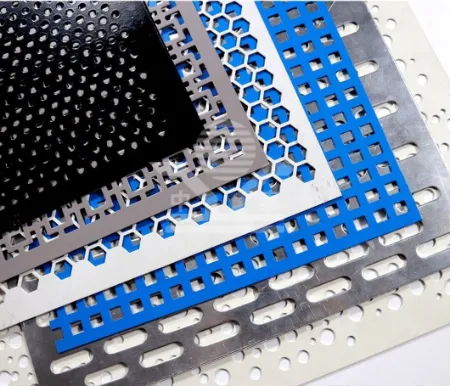

Perforated solutions—ranging from a perforated metal mesh sheet to heavy-duty perforated metal grating and safety-focused perforated metal anti slip tread plate—are essential components in the fabricated metal products ecosystem. In Punching mesh and perforated plate manufacturing, these engineered sheets precisely control airflow, drainage, filtration, light, grip, and weight-to-strength ratios. Typical specifications include mild steel, pre-galvanized steel, aluminum, and stainless steel (304/316) in thicknesses from 0.5–10 mm, hole diameters from 1–50 mm, pitches tailored to open area targets (10–60%+), and patterns such as round, square, slot, and decorative. Metric perforated sheet metal options align with European and global standards, while imperial sizing supports North American retrofits.

For OEMs and project specifiers seeking consistent tolerance and repeatable quality, AnPing Zhongtai Expanded Metal Mesh Co., Ltd delivers metal perforated mesh and mesh perforated sheet with stable flatness, clean sheared edges, and uniform hole geometry. Whether you require a metal sheet with small holes for acoustic panels and enclosures or a robust metal sheet with holes for industrial walkways, Zhongtai’s tooling library and custom punching capabilities shorten lead times, reduce scrap, and support just-in-time supply across diverse manufacturing programs.

Benefits & Use Cases of perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes in Punching mesh and perforated plate manufacturing

In plant environments, perforated mesh panels and grating enable safe platforms, catwalks, mezzanines, machine guards, and screening systems. Anti-slip patterns and raised perforations enhance traction, making perforated metal anti slip tread plate a proven choice for stairs and access ways. In process equipment, a perforated mesh sheet balances structural rigidity with open area for filtration, ventilation, and sound attenuation—crucial in HVAC plenums, compressor housings, and dust collection systems. Metric perforated sheet metal streamlines international builds and spare-part standardization, while tight-tolerance metal perforated mesh elevates visual uniformity for architectural cladding and OEM housings.

Competitive advantages from AnPing Zhongtai Expanded Metal Mesh Co., Ltd include engineered tooling for consistent hole quality, broad metal inventories for faster turnaround, and value-added services such as leveling, shearing, notching, bending, and surface treatments (e.g., powder coating, galvanizing). The result is a metal sheet with holes designed to your performance targets—strength-to-weight efficiency, corrosion resistance, acoustics, airflow, and slip resistance—without sacrificing cost control. From light-gauge mesh perforated sheet for speakers and enclosures to load-bearing perforated metal grating for industrial floors, Zhongtai’s expertise lowers project risk and simplifies installation.

Cost, Maintenance & User Experience

Total cost of ownership improves when the right geometry and material are matched to the duty cycle. A well-specified perforated metal mesh sheet can reduce mass, simplify frames, and cut transport costs. For high-traffic areas, perforated metal anti slip tread plate reduces accidents and downtime, lowering lifecycle costs versus coatings or add-on grit tapes. Stainless and galvanized options extend life in wet or corrosive environments, while paint or powder topcoats align with brand aesthetics and abrasion needs. Maintenance teams value easy-clean surfaces and consistent open areas that resist clogging, particularly in filtration and dust extraction lines.

B2B customers in the fabricated metal products sector report stable flatness and low rework with Zhongtai’s perforated mesh panels, improving assembly throughput. OEMs highlight predictable tolerances that accelerate jigging and welding, while EPC contractors note fewer field modifications thanks to accurate metric perforated sheet metal sizing. Over multi-year operations, the ROI stems from fewer replacements, faster installation, and safer access systems. Whether you need a metal sheet with small holes for precision airflow or heavy-duty perforated metal grating for load-bearing platforms, Zhongtai’s process control helps keep budgets and schedules on track.

Sustainability & Market Trends in manufacturing

Perforated solutions support sustainability by enabling lightweighting, energy-efficient ventilation, and acoustic control. A mesh perforated sheet can reduce fan loads through optimized open area, while a metal sheet with holes in façade systems improves daylighting and shading to reduce HVAC demand. With metals being highly recyclable, material circularity is enhanced at end of life. Growing demand in logistics, data centers, EV production, and food processing drives adoption of corrosion-resistant perforated mesh panels and hygienic stainless options that are easy to sanitize and maintain.

AnPing Zhongtai Expanded Metal Mesh Co., Ltd aligns with these market trends by offering specification-driven engineering support, recyclable material options, and finishing choices that extend service life. The company’s focus on process efficiency, waste reduction, and dimensional accuracy minimizes scrap and rework, supporting both ESG goals and cost competitiveness. As regulations emphasize worker safety and environmental performance, solutions like perforated metal anti slip tread plate and low-emission finishing options position Zhongtai as a forward-thinking, eco-conscious partner for global manufacturers.

Conclusion on perforated metal mesh sheet,perforated metal grating,perforated metal anti slip tread plate,perforated mesh sheet,perforated mesh panels,metal perforated mesh,mesh perforated sheet,metric perforated sheet metal,metal sheet with small holes,metal sheet with holes from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

From lightweight enclosures to heavy-duty platforms, perforated metal solutions deliver airflow, grip, strength, and aesthetics in one engineered package. AnPing Zhongtai Expanded Metal Mesh Co., Ltd combines material range, precision tooling, and value-added services to supply reliable perforated mesh panels, metric perforated sheet metal, and anti-slip tread options with strong ROI. Partner with a manufacturer that understands B2B timelines, quality, and performance.

Contact us: email: hht15531800319@outlook.com

Visit our website: https://www.ztwiremesh.com

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.