Jul . 02, 2024 03:20

Back to list

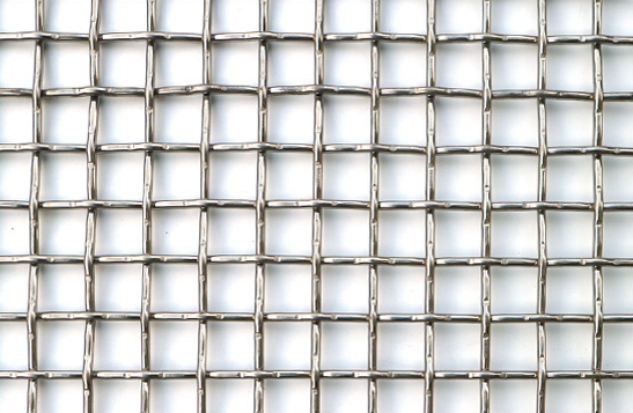

Galvanized Metal Grating Durable and Corrosion-Resistant Solutions for Industrial Applications

Galvanised metal grating, a term that might seem mundane to the uninitiated, is actually an integral part of modern infrastructure and construction. This process involves coating iron or steel with a thin layer of zinc through dipping in a bath of molten zinc or through a hot-dip process. The purpose of galvanisation is to protect the metal from corrosion, thereby extending its lifespan and reducing maintenance costs.

The use of galvanised metal grating spans a wide range of applications, from simple household items like furniture frames and garden trellises to more complex structures such as industrial platforms, walkways, and even bridges. In urban environments, it's not uncommon to see galvanised grating forming sturdy pedestrian pathways over sewage systems, providing both utility and aesthetic appeal.

One of the primary advantages of galvanised metal grating is its durability. The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rusting. When exposed to moisture and oxygen, the zinc reacts first, preserving the structural integrity of the metal beneath. This makes galvanised grating particularly suitable for outdoor uses where weathering is a concern.

Moreover, galvanised metal grating offers excellent value for money. While the initial cost may be slightly higher than that of untreated metal, the longevity and reduced need for replacements or repairs make it a cost-effective solution over the long run. Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste

Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste galvanised metal grating.

In terms of safety, galvanised metal grating also excels. Its open design allows water and other fluids to pass through easily, preventing accumulation that could lead to slipping hazards. This feature also makes it ideal for use in drainage systems and around machinery where spills are common.

From an aesthetic viewpoint, galvanised metal grating can be designed to suit various architectural styles. It can be manufactured in different patterns, sizes, and shapes to complement the surrounding environment. Whether it's used in a sleek, modern building or a traditional landscape, the versatility of galvanised grating ensures that it blends seamlessly into its setting.

In conclusion, galvanised metal grating is a testament to the ingenuity of engineering and the practical application of science. Its ability to withstand the elements, enhance safety, and provide lasting value is a significant contribution to the world of construction and beyond. As we continue to seek materials that balance economy and efficiency with sustainability, galvanised metal grating stands out as a prime example of how these goals can be achieved harmoniously.

galvanised metal grating.

In terms of safety, galvanised metal grating also excels. Its open design allows water and other fluids to pass through easily, preventing accumulation that could lead to slipping hazards. This feature also makes it ideal for use in drainage systems and around machinery where spills are common.

From an aesthetic viewpoint, galvanised metal grating can be designed to suit various architectural styles. It can be manufactured in different patterns, sizes, and shapes to complement the surrounding environment. Whether it's used in a sleek, modern building or a traditional landscape, the versatility of galvanised grating ensures that it blends seamlessly into its setting.

In conclusion, galvanised metal grating is a testament to the ingenuity of engineering and the practical application of science. Its ability to withstand the elements, enhance safety, and provide lasting value is a significant contribution to the world of construction and beyond. As we continue to seek materials that balance economy and efficiency with sustainability, galvanised metal grating stands out as a prime example of how these goals can be achieved harmoniously.

Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste

Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste Additionally, the process of galvanisation is environmentally friendly since it extends the life of the metal, reducing the need for new raw materials and minimising waste galvanised metal grating.

In terms of safety, galvanised metal grating also excels. Its open design allows water and other fluids to pass through easily, preventing accumulation that could lead to slipping hazards. This feature also makes it ideal for use in drainage systems and around machinery where spills are common.

From an aesthetic viewpoint, galvanised metal grating can be designed to suit various architectural styles. It can be manufactured in different patterns, sizes, and shapes to complement the surrounding environment. Whether it's used in a sleek, modern building or a traditional landscape, the versatility of galvanised grating ensures that it blends seamlessly into its setting.

In conclusion, galvanised metal grating is a testament to the ingenuity of engineering and the practical application of science. Its ability to withstand the elements, enhance safety, and provide lasting value is a significant contribution to the world of construction and beyond. As we continue to seek materials that balance economy and efficiency with sustainability, galvanised metal grating stands out as a prime example of how these goals can be achieved harmoniously.

galvanised metal grating.

In terms of safety, galvanised metal grating also excels. Its open design allows water and other fluids to pass through easily, preventing accumulation that could lead to slipping hazards. This feature also makes it ideal for use in drainage systems and around machinery where spills are common.

From an aesthetic viewpoint, galvanised metal grating can be designed to suit various architectural styles. It can be manufactured in different patterns, sizes, and shapes to complement the surrounding environment. Whether it's used in a sleek, modern building or a traditional landscape, the versatility of galvanised grating ensures that it blends seamlessly into its setting.

In conclusion, galvanised metal grating is a testament to the ingenuity of engineering and the practical application of science. Its ability to withstand the elements, enhance safety, and provide lasting value is a significant contribution to the world of construction and beyond. As we continue to seek materials that balance economy and efficiency with sustainability, galvanised metal grating stands out as a prime example of how these goals can be achieved harmoniously. Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP