Jan . 14, 2025 10:18

Back to list

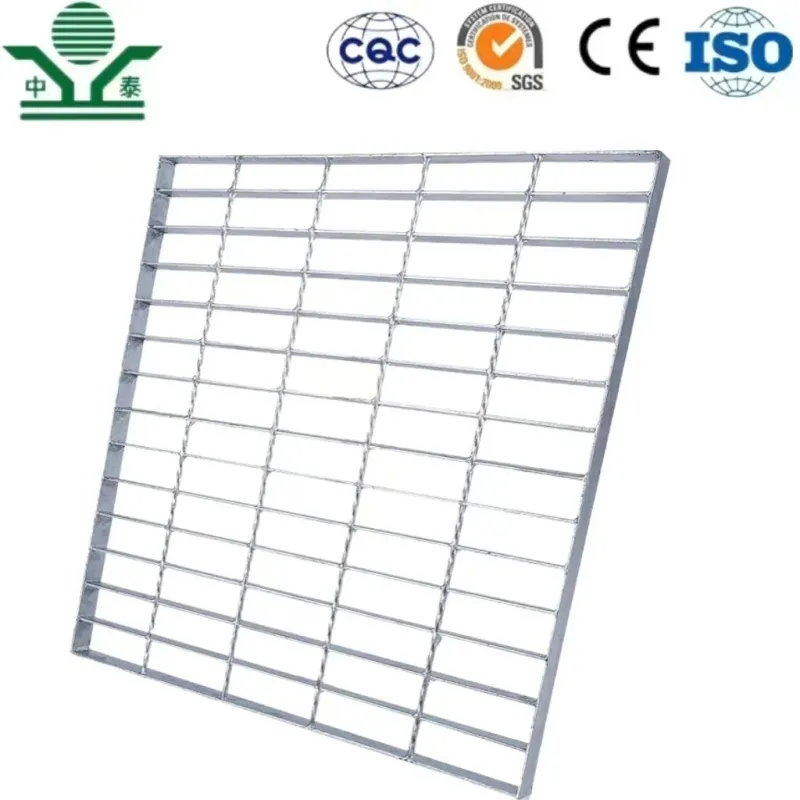

galvanised metal grating

Galvanised expanded mesh stands as a critical component in construction and industrial applications, revered for its versatility, durability, and cost-effectiveness. This article explores the unique properties of galvanised expanded mesh, offering insights drawn from extensive experience in the field to establish its credibility and reliability for both seasoned professionals and newcomers.

Authoritative industry leaders in engineering use galvanised expanded mesh not only for its physical attributes but also for its adaptability in design. Architectural forms often incorporate it to create visually intriguing structures that do not compromise on strength or safety. This mesh can be easily tailored and cut to custom specifications, allowing architects to explore innovative designs while still maintaining the structural soundness required in construction. As a trustworthy material, its application is bolstered by compliance with industry safety standards and building codes. Manufacturers and suppliers ensure the mesh meets stringent quality assurance checks, providing further reassurance to their clients regarding safety and performance. Furthermore, the demand for sustainable materials has seen a rise in the popularity of galvanised expanded mesh, as it is often made from recycled metals, aligning with the push towards eco-friendly construction practices. In conclusion, galvanised expanded mesh offers an unparalleled combination of durability, versatility, and economic value. With extensive industry experience backing its application, expert knowledge ensuring its strategic implementation, authoritative figures endorsing its use, and a trustworthy history of effective performance, galvanised expanded mesh continues to be a top choice for modern construction and industrial needs.

Authoritative industry leaders in engineering use galvanised expanded mesh not only for its physical attributes but also for its adaptability in design. Architectural forms often incorporate it to create visually intriguing structures that do not compromise on strength or safety. This mesh can be easily tailored and cut to custom specifications, allowing architects to explore innovative designs while still maintaining the structural soundness required in construction. As a trustworthy material, its application is bolstered by compliance with industry safety standards and building codes. Manufacturers and suppliers ensure the mesh meets stringent quality assurance checks, providing further reassurance to their clients regarding safety and performance. Furthermore, the demand for sustainable materials has seen a rise in the popularity of galvanised expanded mesh, as it is often made from recycled metals, aligning with the push towards eco-friendly construction practices. In conclusion, galvanised expanded mesh offers an unparalleled combination of durability, versatility, and economic value. With extensive industry experience backing its application, expert knowledge ensuring its strategic implementation, authoritative figures endorsing its use, and a trustworthy history of effective performance, galvanised expanded mesh continues to be a top choice for modern construction and industrial needs.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP