Jan . 14, 2025 10:15

Back to list

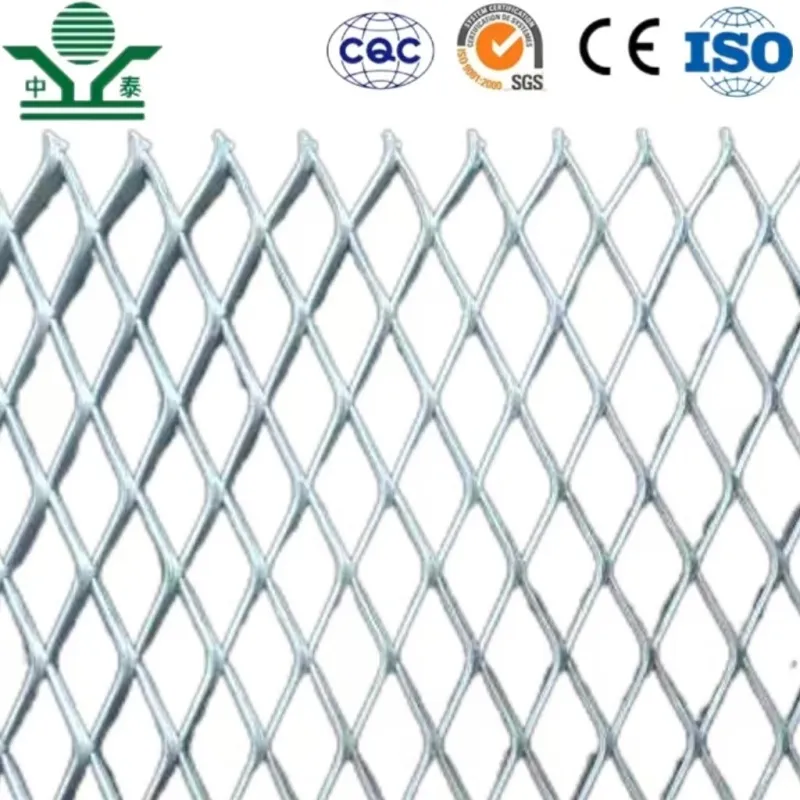

expanded mesh panels

Galvanized expanded mesh is a standout choice when considering robust and versatile materials for construction, industrial, and architectural purposes. Its unique properties and wide-ranging applications make it an invaluable asset for professionals seeking reliability and durability. With over a decade of experience in the metals industry, I've seen how galvanized expanded mesh has revolutionized the way we approach building and maintenance projects.

From an authoritative perspective, industry standards and certifications provide guidelines on the use of galvanized expanded mesh in various applications. Adherence to these standards not only ensures safety and reliability but also affirms the trustworthiness of the product. It's vital for designers and builders to stay informed about the latest advancements and regulatory changes to maintain compliance and achieve optimal results. For those new to galvanized expanded mesh, partnering with a reputable supplier is critical. The supplier should offer not only high-quality products but also the technical support necessary to tailor solutions to specific needs. A trustworthy supplier will have a proven track record, positive client testimonials, and a commitment to continuous improvement and innovation. In conclusion, galvanized expanded mesh represents a blend of technological advancement and practical application. Its role in modern construction and design is supported by experience-backed insights and expert understanding, while its resilience and adaptability underscore its authoritative position in the industry. As projects become increasingly complex and demanding, the reliability of materials like galvanized expanded mesh will continue to be a beacon of trust and excellence for professionals worldwide.

From an authoritative perspective, industry standards and certifications provide guidelines on the use of galvanized expanded mesh in various applications. Adherence to these standards not only ensures safety and reliability but also affirms the trustworthiness of the product. It's vital for designers and builders to stay informed about the latest advancements and regulatory changes to maintain compliance and achieve optimal results. For those new to galvanized expanded mesh, partnering with a reputable supplier is critical. The supplier should offer not only high-quality products but also the technical support necessary to tailor solutions to specific needs. A trustworthy supplier will have a proven track record, positive client testimonials, and a commitment to continuous improvement and innovation. In conclusion, galvanized expanded mesh represents a blend of technological advancement and practical application. Its role in modern construction and design is supported by experience-backed insights and expert understanding, while its resilience and adaptability underscore its authoritative position in the industry. As projects become increasingly complex and demanding, the reliability of materials like galvanized expanded mesh will continue to be a beacon of trust and excellence for professionals worldwide.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP