Perforated metal and expanded metal are the results of superior processing and manufacturing of an ordinary sheet of metal. Their durability, strength and functionality play a vital role in many industrial and construction applications. In addition, infinite reveries of geometric patterns can be realized on them, which offers the possibility of creating an aesthetic structure for your project.

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

But while these two types of metal panels may look similar, there are actually many differences, and it is essential to understand the differences when making a choice for your project. This will avoid unnecessary hassles, may save you money, and may allow your project to be completed better.

Expanded Metal Mesh vs. Perforated Metal Sheet

So do you really know them? Yes, they are similar, they are made of a sheet of metal, they are made with holes, they are very durable, they can be “dyed” and have many overlapping uses. However, their specific capabilities are very different, and they all have their unique characteristics and the same characteristics that are inferior compared to the other side.

Sometimes they may be made of the same metal material, but show significant differences in performance and function due to completely different manufacturing methods. So you will have to choose one of them to make it better match your project.

In this article, we will explain the difference between expanded metal and perforated metal in detail with our experience. Hope this will be of help to you.

What is Expanded Metal?

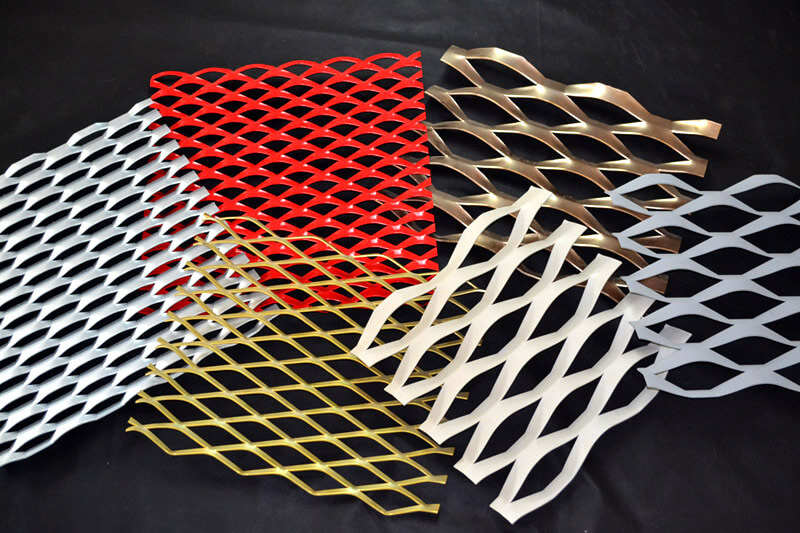

Expanded metal mesh is the result of a sheet metal process. A sheet of metal is mounted on an industrial die-cutting machine, cut and stretched to form a mesh-like sheet. The knives on the machine usually move back and forth in a uniform pattern, alternately cutting the sheet metal while it moves through the machine. After the stretching process, some strands may protrude slightly and can be flattened if a 2D flat surface is desired.

The manufacturing process of expanded metal mesh produces no scrap (which reduces production costs) and also maintains or increases the structural strength of the final product.

Opening Pattern

Stretching the sheet metal creates regular diamond-shaped openings. Although many different styles can be created, they always seem to be “diamond-shaped”. These diamond-shaped holes can be in a straight line with all rows and columns aligned, or they can be staggered (not aligned). And the size of the openings affects the performance of the expanded metal sheet, such as the amount of fluid, air or light that passes through.

Available Materials

Expanded metal mesh is usually made of aluminum, stainless steel, galvanized steel, etc. Copper, brass, nickel and titanium can also be used.

What is Perforated Metal?

Again, starting with a sheet of metal, the sheet is mounted on a punch or laser cutter and then punched with a pre-defined pattern (usually designed by software such as CAD). In order to reduce the impact on the stability of the structure, a certain distance is usually reserved on all sides of the metal plate will not be perforated.

The perforation process is due to stamping directly on the sheet metal, so scrap is bound to be generated. Although the scrap is recyclable, it does add some cost. In particular, the waste caused by manufacturing metal plates with larger hole diameters is also increased. And the overall structural strength will also be reduced.

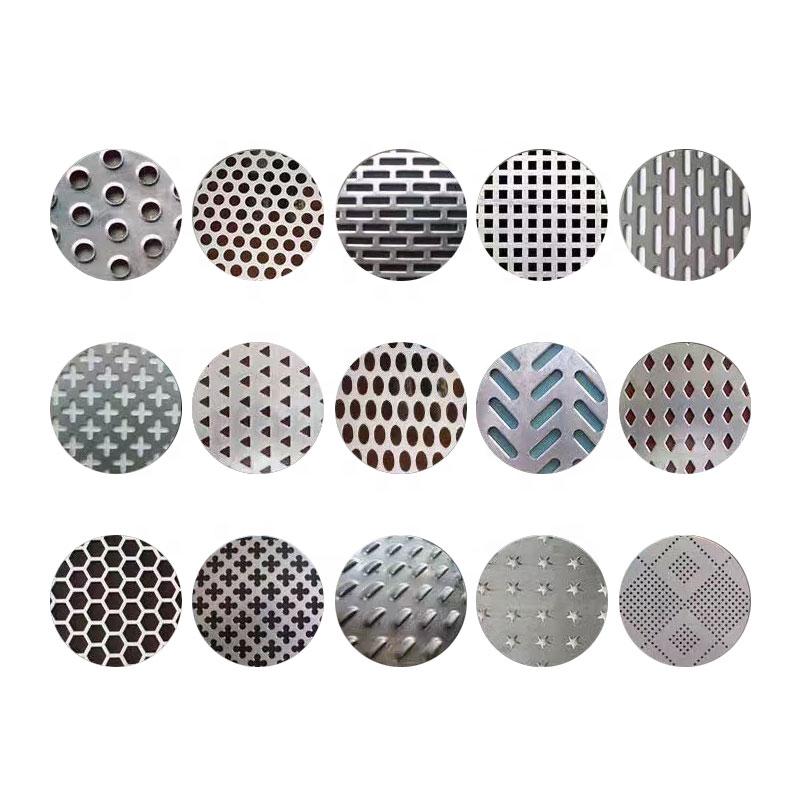

Opening Pattern

Perforated metal sheets are available in a wide variety of openings, the basic ones being round, square, slotted and hexagonal holes. Different arrangements, sizes and designs allow for a wider variety of combinations of hole shapes and patterns. These can also affect the performance and function of perforated metal sheets.

Available Materials

As with expanded metal mesh, almost any material can be perforated, the more popular ones are aluminum, stainless steel, galvanized steel, plain steel, etc. The less popular ones are copper, brass, titanium plate, etc. Even some non-metal sheets are perforatable.

Comparison of Key Features

After briefly understanding the two products, we can then delve into their differences.

Manufacturing Costs Comparison

In this respect, expanded metal mesh is undoubtedly superior to perforated metal sheets. As we mentioned above, perforated metal produces waste in the production process and the waste caused by the increase in the range of openings is also elevated. And expanded metal produces no scrap in the production process and almost zero waste.

It follows that if it is for a use where both are available, then expanded metal is more cost effective.

Structural Strength Comparison

Expanded metal has better structural strength than perforated metal because expanded metal only cuts and stretches the sheet metal without causing damage to the sheet metal as perforated metal does. So it creates building materials that provide greater structural strength, integrity and stability.

So if your project has a need for strong materials, then expanded metal is more appropriate.

Decoration Design Comparison

Both metals are available for aesthetic decorative purposes, which is their common advantage. The difference is that perforated metals have more design flexibility than expanded metals.

The holes in expanded metal mesh are usually diamond, elliptical or hexagonal holes. These holes can then be combined into different patterns by changing the size, arrangement and curvature of the sides. In addition, expanded metal is not just a 2-D flat sheet metal, it is also available in a 3-D form, which is a raised design. This feature is not available in perforated metal.

The advantage of perforated metal is its design flexibility. As mentioned above, the basic hole shapes of round, square, slotted and hexagonal holes can be designed individually and can be arranged and combined to create more patterns. Compared to expanded metal mesh, it can provide more decorative pattern designs.

But this is not enough, through the professional computer software, advanced turret punch and laser cutting machine, you can “draw” on the perforated metal plate. This means that almost any pattern, text or even a photo can be realized on perforated metal sheets. This is a key feature that is absolutely ahead of expanded metal.

Acoustic Optimization

Sound insulation and acoustic optimization are key features of perforated metal, which can muffle, block or soften sound in some structures in a way that expanded metal mesh does not. In the design process of concert halls, cinemas, multi-purpose halls and other places, perforated metal with sound absorption characteristics have gained very wide application as a technical means of sound quality design and noise control.

Application Comparison

Perforated and expanded metals differ not only in their manufacturing methods and properties. Correspondingly, they also have their own more suitable application industries, although some overlap.

They are both commonly used in industrial facilities, construction sites or some commercial building applications. The difference is that expanded metal is more common in stair treads, walkways, catwalks and floor grilles, which require better load-bearing capacity and structural strength. Perforated metal is more commonly used for building facades, backdrops, ceilings, fences and partitions. Some large office buildings or corporate structures can benefit from the decorative, functional and sound deadening properties of perforated metal.

In addition to architectural uses, they can also be manufactured as accessories for many household and industrial products such as protective covers, shelving, containers, speaker grilles, lighting equipment, filtration and sieving applications, and more.

So how should you choose?

If you are still not sure how to choose your project, then let’s summarize it together again, which may help you complete your decision more intuitively.

| Comparison | Expanded Metal Mesh | Perforated Metal Sheet |

|---|---|---|

| Available Materials | All can be made of aluminum, stainless steel, plain steel, galvanized steel, copper, brass, etc. | |

| Manufacturing Method | Cutting and stretching, or flattening for 2D plates | Stamping or laser cutting |

| Scrap | Few or none | Scrap will be generated, and more waste will be generated as the hole size increases |

| Cost | Lower | Middle or high |

| Hole Shape | Diamond-shaped hole, hexagonal hole, near-elliptical hole | Round hole, square hole, slotted hole, hexagonal hole, etc. Almost any hole shape can be made by designing the mold |

| Structural Strength and Stability | Excellent | General |

| Design Flexibility | Create 2D or 3D patterns by changing the style, size and arrangement of the holes | Create 2D patterns by changing the style, size and arrangement of the holes, and also allow for more complex pattern designs such as text and images |

| Durability | Durability is guaranteed by the use of corrosion-resistant materials, and this can be enhanced by surface treatment | |

| Sustainability | All environmentally friendly and recyclable materials | |

| Architectural Use | Building facades, fences, sunshades, room dividers, ceilings, infill panels, etc. More suitable for stair treads, walkways and floor grilles where load-bearing capacity is required | Building surface cladding, interior and exterior walls, sunshades, fences, ceilings, room dividers, screens, louvers, acoustic panels, stair treads, vents, etc. |

| Other Applications | Filtration, sieving, food processing, speaker grilles, storage cabinets, automotive components, furniture, shields, structural components, etc | |

Are they look the same but have many differences? That’s why we recommend that you best make your choice based on your specific needs and budget. Whether it is the low manufacturing costs and structural stability of expanded metal or the decorative and functional nature of perforated metal. They all have suitable areas of application. There is no perfect metal, only the most suitable choice.

What can we provide?

Perhaps you are still unsure of which metal product to choose for your project? Don’t worry, tell us your needs and we will recommend the most suitable solution for you with our years of experience. Whether it’s a large project like a building façade or manufacturing a small product like a filter cartridge, we have a dedicated sales and engineering team to help you with design and calculations.

We will make sure you get the right product for your application and requirements.

You may have doubts that perforated metals are introduced on this website. What about expanded metal? As this article says, they look just as much alike, so we also have the ability to manufacture expanded metal products, whether it’s material, design, or plate shape that can be customized for you.

You can contact us now to learn more about our products or us. Get advice on choosing a more suitable product for your project.