You probably see, use, or come into contact with expanded metal products daily without even realizing it. Raised, grated, or flattened expanded metal has found lots of uses in industrial settings and households across the world.

However, not all manufacturers of metal are quite the same. Considering that when you buy things like expanded metal sheets you expect them to last you for many years, it can be very disappointing to find yourself with some poor-quality products on your hands.

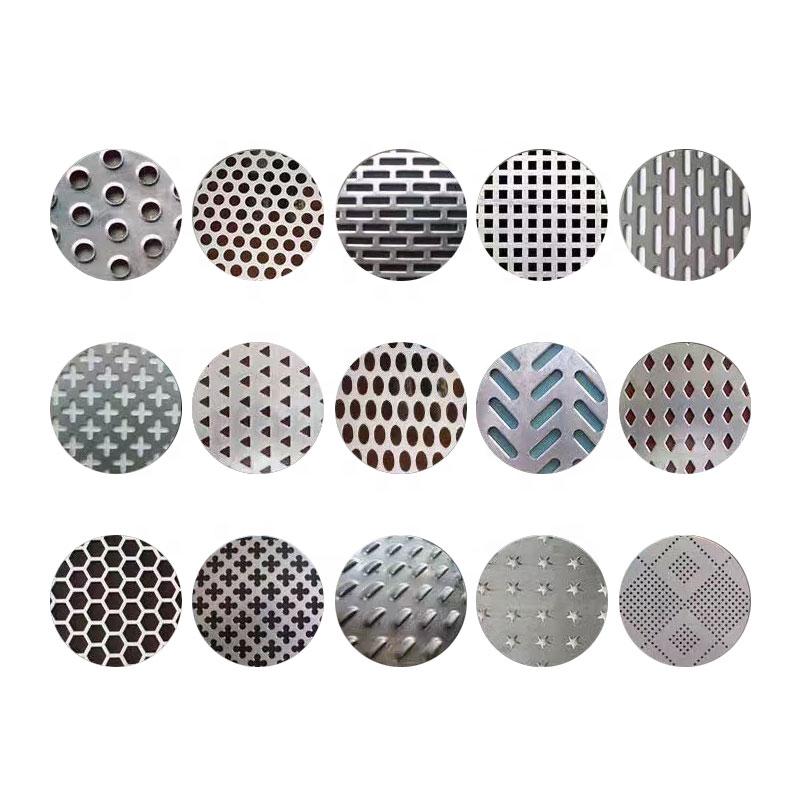

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

If you want a uniquely shaped expanded metal grating, you can take advantage of the customization option to create the perfect product for your needs.

What Is Expanded Metal?

If you have ever seen steel products with diamond-shaped openings usually used on cages, grates, or barriers, then you have a good idea of what expanded metal sheets look like.

Expanded metal is simply metal that has been cut and stretched with regular diamond-shaped openings. Mechanically opening up the sheet creates a larger surface area than the original sheet.

There are different types of expanded metal sheets, differentiated by gauge, size of the diamond-shaped openings, and type of materials used. These different types are made specifically for various industrial applications.

How Is Expanded Metal Made?

This type of metal is made from a flat sheet of what is normally steel. Using a specialized expansion process, the sheets can be expanded up to 10 times their original size, which is where the name expanded metal comes from.

By pulling the metal sheets in two different directions, they are stretched until the diamond-shaped openings are created on the smooth surface.

A powerful blade is then used to cut through the diamond shapes until the diamond-shaped mesh design you are familiar with is created.

Five Common Types of Expanded Metal

Depending on the type of steel expanded and the expansion process, you can end up with one of five common types of expanded metal sheets, which are:

Standard Expanded Metal

Although it is called standard expanded metal, this is actually the more expensive type of expanded metal product you can find. It is made by using a square grind in which the diamond patterns are cut out.

What makes standard expanded metal so expensive is the high strength-to-weight ratio it has while at the same time being quite corrosion resistant.

Flattened Expanded Metal

If you are looking for a cheaper option and do not mind compromising on the strength and durability of your products, you can try out the flattened expanded metal sheet.

The advantage of this type of sheet is that flattened expanded metal is much lighter and cheaper than most other types of steel in this category.

Expanded Metal Grating

Those looking for the most economic industrial solution for adding more traction to floor grating need look no further than expanded metal grating.

The design of this type of floor grating is much thicker and has bigger gaps in the diamond pattern to increase drainage and air circulation while maintaining a slip-resistant surface.

Ribbon Expanded Metal

The unique expansion process used to make ribbon expanded metal makes it a good option if you are looking for a product that is highly resistant to wear and tear.

Cutting the diamond pattern horizontally also gives the ribbon expanded metal a lot more stability than flattened expanded metal.

Raised Expanded Metal

Last, but not least, is raised expanded metal. With this type of steel, expanded metal sheets are slit and stretched in a longitudinal direction which not only gives the sheets a lot of strength but improves their stability as well.

Special Characteristics of Expanded Metal

There are many other types of steel that can be used for similar applications to that of expanded metal sheets but it is their special characteristics that give them the edge.

It is only with expanded metal that you get the high strength-to-weight ratio that you do not get with, for example, wire mesh products.

When you use flattened expanded metal, the material does not need to be welded together and can be used as one continuous piece, which is great for minimizing creases that reduce the strength and stability of similar products.

The most common shape for the openings on expanded metal sheets is diamond, which is favored for its strength and resistance to deformation.

However, the versatility of the expansion process is such that you can create a flattened expanded metal sheet with circular or square shapes just as easily.

It is also easy to combine an expanded metal sheet with a wide range of different materials, and as a result, aluminum, carbon steel expanded metal, and stainless steel expanded metal are all quite common.

Typical Uses of an Expanded Metal Sheet

There are so many possibilities when it comes to expanded metal that the only limit is your imagination. These products can easily be used for the following:

- Creating a mechanical barrier

- Machine guards

- Drainage covers

- Light diffusers

- MI/RFI Shielding

- Drive and sidewalk grates

- Security mesh a/c covers

- Concrete reinforcement

- Window, door, and skylight guards

- Cab/truck dividers

- Walkways, mezzanines, stairways, and ramps

- Expanded metal infill panels used in all industries

- Air intake screens

- Catwalk grating and anti-slip flooring

What Benefit Does Expanded Metal Provide vs. Plain Sheet Metal

The process of expanding metal actually increases its strength rather than weakens it and produces a much lighter product. This is the major advantage it has over plain sheet metal.

Also, if an anti-slip surface is what you are looking for, expanded metal is the far better option because it has knuckles that develop from the process of expansion and these add to the grip of the flattened expanded metal sheets.

Different Types of Expanded Metal Finishes and Treatments

Each particular application requires a specific type of finishing or treatment for your flattened expanded metal or another type of expanded metal sheet. Consider the following:

Mill Finish

There are two types of mill-finished expanded metal you could choose from namely:

Carbon steel expanded metal

If you have a carbon steel expanded metal sheet, you will want to clean it with a solvent bath or acid and finish off with water

Aluminum Steel expanded metal

The best way to clean aluminum steel expanded metal is to use a non-etching chemical or detergent before rinsing and drying.

Leveling

This is created by leveling the plane of the expanded metal sheet without flattening stands or bonds.

Deburring

This is created when burrs and sharp edges/exposed edges are removed using a wire brush.

Electro-galvanized Steel

Coating the expanded metal with zinc using an electric current. It is great if you are looking for a weather-resistant coating.

Hot-dip Galvanized Steel

This is a very protective zinc coating used when looks are not the biggest concern because the coating usually leaves a rough, uneven surface.

Anodized, Coated, Painted, or Plated expanded metal is also available if you are looking for a more specialized type of finish.

Consider Open Area Percentage on Diamond-Shaped Openings

The amount of space you leave in your diamond patterns is important for determining how well the air will circulate. Small openings tend to be very restrictive in terms of airflow so make sure you choose very carefully when determining which size to go for.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.