In the diverse realm of materials and design, the expanded metal sheet stands out as a marvel of versatility and ingenuity. Often overlooked in the shadow of its more prominent counterparts, this unique configuration offers a delicate balance of strength, flexibility, and aesthetics. Moreover, by widening its application from industrial environments to architectural spaces, expanded metal sheets are a testament to innovative engineering.

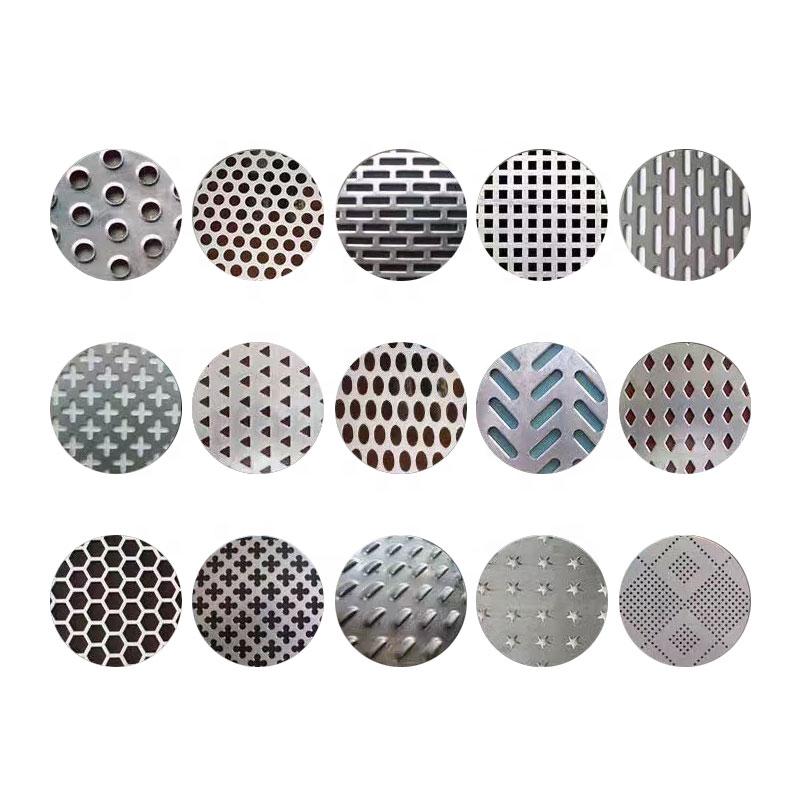

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

What Makes Expanded Metal Sheet an Industry Favorite?

Creating expanded metal sheets is an intricate procedure involving sheet metal stretching, slitting, and rolling. A specialized machine elongates the metal, then strategically slices it using upper and lower blades to yield diamond-shaped voids. Moreover, these voids offer inherent structural integrity without extra fortification and grant the metal its distinctive mesh appearance. After undergoing the die-cut, the sheet is smoothened using a rolling mill.

A salient feature of this method is its zero wastage of metal, resulting in a robust, adaptable metallic product. Furthermore, it can be tailored into specific sheet dimensions or rolled into coils, catering to diverse industry demands.

Applications of Expanded Metal Sheets

Expanded metal sheets are the unsung heroes in various industrial and artistic applications, combining durability and adaptability. With its customizable die-cutting process, the range of uses spans from intricate sculptures to modern architectural facades.

Machine and Window Guards

They protect against external hazards such as debris, accidental contact, or unauthorized access. Moreover, they are made from materials like metal, they are designed to be durable yet transparent, allowing for easy monitoring of machinery and visibility through windows. In this way, they balance operational needs and safety requirements.

Catwalks, Platforms, and Stair Treads

These provide grip and durability, serving as the cornerstone of safe industrial movement and accessibility. As a result, they reduce the likelihood of workplace accidents and facilitate smoother operations. Consequently, these structures are indispensable in optimizing safety and efficiency in industrial settings.

Screens and Flooring

Screens and flooring are employed in diverse settings, combining aesthetic allure with structural integrity. As a result, they not only elevate the visual aspects of a space but also ensure its functional stability. Consequently, these elements serve a dual purpose of enhancing form and function in various environments.

Railing Mesh

Railing mesh is featured in locations such as stairways, balconies, and construction sites, seamlessly merging aesthetic value with safety features. Doing so elevates the design elements and fortifies the structure against potential risks. Hence, railing mesh is a harmonious blend that fosters secure movement while enhancing visual appeal.

Conveyor Belts

Conveyor belts are ubiquitous in sectors where the transit of materials is key, offering a unique combination of strength and flexibility. Because of this, they can handle a wide range of objects while adapting to various industrial demands. Thus, conveyor belts are integral components that significantly bolster production lines’ effectiveness and adaptability.

Racks and Shelving

Racks and shelving are widely used in retail and storage environments, serving the dual purpose of maximizing space and supporting substantial weight. In this context, they enhance both the organization and the utility of the setting. Therefore, these structures are invaluable for efficient space management and inventory control.

Fire Pits and Grills

Fire pits and grills are engineered to withstand extreme heat, making them well-suited for cooking and heating tasks. As a result, they provide a reliable and effective solution for a range of culinary and warmth-generating needs. Consequently, these appliances are integral for enhancing the quality and versatility of outdoor or recreational spaces.

Soundproofing

Soundproofing materials are instrumental in mitigating noise in both residential and commercial settings. Due to this, they contribute to more comfortable and focused environments, free from the disruption of external sounds. Hence, these noise-dampening sheets are valuable resources for enhancing quality of life and workplace productivity.

Stereos and Microphones

Stereos and microphones serve to amplify and refine sound quality, becoming integral components in the design of audio equipment. Because of this, they are indispensable for ensuring clarity and richness in recording and playback scenarios. Therefore, these devices are key in elevating the overall audio experience in various applications, from entertainment to professional settings.

Outdoor Equipment

Outdoor equipment, ranging from park benches to playground installations, is designed to offer both durability and safety. As a result, these structures can withstand weather conditions and frequent use while minimizing risk. Consequently, such equipment plays a significant role in promoting public well-being and leisure activities.

Air and fluid filters/strainers

Air and fluid filters, along with strainers, are integral components of filtration systems designed to remove impurities and provide cleaner air and liquids. As a result, they play a pivotal role in maintaining environmental quality in both industrial and domestic settings. Therefore, these filtration elements are key to safeguarding health and optimizing the performance of various systems, from HVAC units to water treatment plants.

Shielding

Shielding is a barrier against electromagnetic and radio frequency interferences, a fundamental aspect of electronics design. As a result, it ensures that devices operate without disrupting or losing data integrity. Consequently, shielding is indispensable for the reliable and secure functioning of a wide array of electronic products.

Ventilation Systems

Ventilation systems are designed to manage airflow effectively while preventing debris ingress, making them a central element in HVAC configurations. Because of this dual functionality, they create comfortable and clean environments. Thus, ventilation systems are essential for optimal indoor air quality and thermal comfort.

Decorative Dividers and Partitions

Decorative dividers and partitions blend aesthetic qualities with practical utility, reshaping interior and exterior spaces. As a result, they organize and delineate areas while adding visual interest. Consequently, these design elements act as versatile tools for enhancing the ambiance and utility of various settings.

Security Walls, Ceilings, Floors, and Doors

Security walls, ceilings, floors, and doors are designed to fortify structures against unauthorized entry, enhancing overall security measures. In doing so, they offer a robust line of defense against intrusion attempts. Hence, these components are integral for maintaining a safe and secure environment in residential, commercial, or industrial settings.

Concrete Reinforcements

Concrete reinforcements are employed to fortify structures, adding rigidity to concrete-based constructs. As a result, they extend the lifespan and enhance the load-bearing capacity of various architectural forms. Therefore, these reinforcements are critical for ensuring concrete buildings and infrastructures’ long-term stability and safety.

Greenhouses

Greenhouses are designed to create an optimal plant growth environment while offering protection from pests and harsh weather. As a result, they facilitate a more controlled and productive cultivation process. Consequently, greenhouses are invaluable assets for hobbyist gardeners and commercial agricultural operations.

Understanding the Role of Expanded Metal Mesh

Originating from a solitary sheet of meticulously compressed and elongated material, the expanded metal mesh is a testament to innovation and functionality. Moreover, its unique fabrication process sets it apart from traditional metal or wire meshes, endowing it superior strength, especially when compared to finer metal meshes.

One of the striking advantages of expanded metal is its enhanced airflow and drainage capacities. This suits it, particularly for environments where ventilation and moisture management are paramount. Moreover, its robust nature and design versatility have cemented its status as the preferred choice for constructing wire baskets, among other applications.

Furthermore, beyond these uses, the resilience and adaptability of the expanded metal make it an invaluable asset across various industries, demonstrating its versatility and the ever-increasing demand for its incorporation into modern design and utility solutions.

Diverse Applications of Expanded Metal Mesh

Metal mesh is not just any ordinary material; its unique properties lend it to various demanding industrial tasks. Moreover, especially when crafted into baskets, they’re instrumental in high-stress operations like shot peening and shot blasting, offering the resilience to withstand the intense stresses these processes invoke persistently.

Beyond high-impact scenarios, these baskets crafted from expanded metal mesh are preferred for storage, organization, packaging, and transportation tasks. Furthermore, their superior surface quality ensures long-term durability, even when faced with the rigors of outdoor environments.

Moreover, the protective nature of expanded metal mesh is particularly evident in its fire-resistant capabilities. Furthermore, this makes it an essential component in devices that demand high heat tolerances and sufficient airflow, such as fire pits, grills, heaters, and other heat-intensive equipment.

Unveiling the Strengths of Expanded Metal

Efficiency and Conservation: Unlike other methods, such as perforation, which involves punching out material, the fabrication of expanded metal stretches and cuts ensures zero metal waste.

Featherlight Durability: Flattened or expanded metals boast a lightweight profile without compromising strength.

Hassle-free Upkeep: Often accompanied by a rust-resistant coating, maintaining metal grating is straightforward, minimizing long-term costs and labor.

Versatile Environments: Be it indoors or outdoors, expanded metal sheets effortlessly adapt, underscoring their all-rounded utility.

Robust Reinforcement: When combined with materials like glass or concrete, expanded metal mesh contributes significantly to enhanced structural integrity.

Superior Load-bearing Capacity: Expanded metals exhibit higher tensile strength, outperforming woven metals and jointed welds, making them capable of supporting greater weights and stresses.

Unhindered Flow: The expanded metal design allows for seamless air and light circulation. Moreover, this design also facilitates the easy passage of liquids, debris, and other substances.

Acoustic Excellence: As an integral component in audio equipment like microphones and speakers, the expanded metal mesh also shines in soundproofing spaces, enhancing acoustics and dampening unwanted noises.

Deciphering Expanded Metal Terminology

Navigating the world of expanded metal sheets requires familiarity with specific jargon. These terms are pivotal for grasping the nuances of expanded metal dimensions and the broader scope of related products. Moreover, the reference image portrays a standard expanded metal variant, with highlighted zones demonstrating the elevated, anti-skid edge feature.

Bond: The junction where two neighboring strands converge. Furthermore, it’s important to note that a bond’s width is always double that of the strand.

Strand: Refers to the individual metal strip that delineates the boundary of an opening.

Strand Width: Represents the quantity of metal advanced during the expansion process.

Strand Thickness: Specifies the depth of the original metal sheet from which the expanded version is derived.

Opening / Aperture Size: While most commonly diamond-shaped, the open space framed by the strands and bonds can differ based on distinct die-cutting methods.

SWO or SWA (Short Way of Opening/Aperture): This measures the distance across the sheet, paralleling the shorter side of the diamond, and only factors in the opening’s size.

LWO or LWA (Long Way of Opening/Aperture): Conversely, this gauges the distance parallel to the longer diamond side, considering solely the expanse of the opening.

Mesh: Indicated in inches, it’s the average distance from one bond’s center to the center of its neighboring bond, taken across the SWA.

Percent of Open Area: A crucial metric for professionals, this quantifies how much elements like light or air can traverse the expanded metal.

Pitch: Denotes the span from a specific point on one diamond to the identical point on its neighboring diamond. Furthermore, this measure might vary across the sheet in some ornamental patterns.

Style: For expanded metal, the style is denoted by the gauge number, indicating the metal’s thickness before expansion. Moreover, metal grating is expressed in weight per square foot terms.