Exploring the Benefits of 1% 204% Perforated Aluminum Sheets

Perforated aluminum sheets have become an essential material across various industries due to their lightweight nature, durability, and versatility. Among these, the 1% 204% perforated aluminum sheet stands out as a remarkable option, featuring a unique hole pattern that provides both aesthetic appeal and functional benefits. This article provides an overview of what 1% 204% perforated aluminum sheets are, their applications, and the advantages they offer.

What is 1% 204% Perforated Aluminum Sheet?

Perforated aluminum sheets are metal sheets that have been punched with holes in various patterns and sizes. The designation 1% 204% typically refers to the percentage of perforation and the dimensions or spacing of the holes. In this case, 1% indicates that 1% of the sheet's surface area is made up of the holes, while 204% could refer to the specific dimensions or the pattern used in the perforation process. As a result, the sheets provide a balanced combination of solid material and open space, which can be optimized for different uses.

Applications of 1% 204% Perforated Aluminum Sheets

1. Architecture and Design The unique appearance of perforated aluminum sheets allows architects to incorporate them into building facades, decorative panels, and sunshades. The permeability offered by the holes not only adds visual interest but also helps in managing light and airflow.

2. Industrial Use In manufacturing, these sheets are often used in machinery guards, safety screens, and ventilation grilles. Their strength and lightweight properties make them easy to install and effective in providing safety while maintaining visibility.

3. Automotive Industry The automotive sector utilizes perforated aluminum sheets for different applications, including grilles, heat exchangers, and decorative elements in vehicle interiors. The corrosion resistance of aluminum is another significant advantage in this industry, protecting components from environmental damage.

4. Furniture Design As interior design evolves toward more contemporary styles, perforated aluminum sheets are increasingly used in furniture design. This material adds a modern touch to pieces like partitions, coffee tables, and shelving units, allowing for light transmission while maintaining privacy.

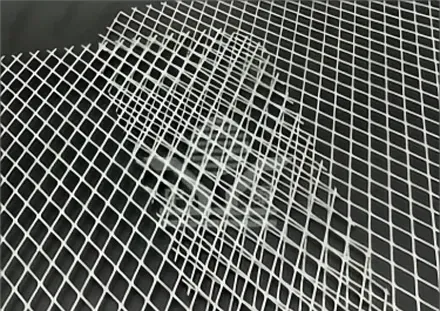

1 4 perforated aluminum sheet

5. Acoustic Applications With the ability to manipulate sound waves, perforated aluminum sheets can be used in acoustic panels to enhance the sound quality in various environments, such as concert halls, theaters, and offices. The strategic placement of the holes can help in sound absorption and diffusion, creating a better auditory experience.

Advantages of 1% 204% Perforated Aluminum Sheets

1. Lightweight and Durable One of the major advantages of aluminum is its light weight combined with high strength. This property not only makes it easy to handle and install but also reduces the load on supporting structures.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer, making it resistant to rust and corrosion. This characteristic is particularly beneficial for outdoor applications where exposure to the elements is inevitable.

3. Easy Maintenance Perforated aluminum sheets are easy to clean and maintain, an important factor for applications in industries such as food processing and healthcare. Regular cleaning with mild detergents can keep the sheets looking new and functional.

4. Customization Manufacturers can customize the hole patterns, sizes, and configurations to meet specific needs. This adaptability allows clients to achieve the desired aesthetics and functionalities for their projects.

5. Sustainable Option Aluminum is a recyclable material, making perforated aluminum sheets an environmentally friendly choice. Using sustainably sourced materials and promoting recycling can significantly reduce the carbon footprint of various industries.

In conclusion, the 1% 204% perforated aluminum sheet is a versatile and efficient material suited for a multitude of applications. Its unique properties not only enhance the functionality of products but also contribute to aesthetic and sustainable design practices. As industries continue to evolve, the demand for innovative materials like perforated aluminum sheets will likely increase, shaping the future of design and manufacturing.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.