The Importance of Galvanized Steel Treads in Industrial Applications

Galvanized steel treads are an essential component in various industrial and commercial applications, providing safety, durability, and cost-effectiveness. These treads are typically made from steel that has undergone a galvanization process, which involves coating the steel with a layer of zinc to protect it from corrosion. As industries increasingly prioritize safety and longevity in their structures and equipment, galvanized steel treads have become a popular choice across the globe.

Advantages of Galvanized Steel Treads

1. Corrosion Resistance One of the primary benefits of galvanized steel treads is their resistance to corrosion. The zinc coating acts as a barrier, preventing moisture and oxygen from reaching the steel beneath. This is especially crucial in environments that are prone to moisture, such as manufacturing facilities, outdoor landscapes, and areas exposed to certain chemicals. The extended lifespan of galvanized treads due to this protective coating makes them a cost-effective option in the long run.

2. Enhanced Safety Safety is always a top priority in any industrial environment. Galvanized steel treads often feature non-slip surfaces, providing better traction for workers, which reduces the risk of slips and falls. This feature is particularly beneficial in high-traffic areas where safety hazards are more prevalent. Companies that prioritize the safety of their employees not only protect their workforce but also mitigate the risk of accidents that could lead to costly legal issues.

3. Durability and Strength Galvanized steel is known for its strength and durability. Steel is a robust material capable of bearing heavy loads, and when galvanized, it receives an additional layer of protection against wear and tear. This makes galvanized steel treads suitable for applications involving heavy machinery or high foot traffic. Their durability helps in maintaining structural integrity over time, thereby reducing the need for frequent replacements.

galvanized steel treads

4. Versatility Galvanized steel treads can be used in a variety of applications, from staircases and platforms to walkways and industrial ramps. Their versatility makes them a preferred choice for construction projects in warehouses, factories, and commercial buildings. Furthermore, they can be easily customized to meet specific design and functional requirements, making them adaptable to different environments.

5. Environmental Considerations Increasingly, companies are becoming aware of their environmental impact. Galvanized steel can be recycled, which makes it a sustainable choice for construction materials. Utilizing recycled materials and products can lead to reduced carbon footprints and support green building practices.

Installation and Maintenance

Installing galvanized steel treads is a straightforward process, often involving standard tools and techniques familiar to construction professionals. Once installed, minimal maintenance is required. Regular inspections should be conducted to identify any wear or potential damage, but the corrosion-resistant properties of galvanized steel significantly reduce maintenance concerns.

Conclusion

In conclusion, galvanized steel treads are a vital component in industrial and commercial applications, providing a combination of safety, durability, and versatility. As industries continue to focus on enhancing workplace safety and reducing long-term costs, the demand for galvanized steel treads is likely to grow. By investing in these reliable and resilient treads, companies can not only ensure the safety of their employees but also contribute to a more sustainable future. Whether in manufacturing, warehousing, or construction, galvanized steel treads offer an effective solution that meets the diverse needs of today's industrial environments.

-

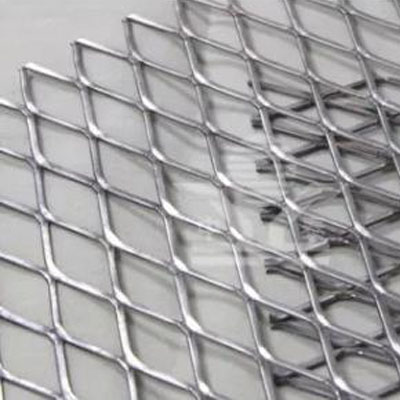

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.