The Versatility and Applications of Punched Copper Sheets

Punched copper sheets are an indispensable material in various industries, renowned for their unique combination of durability, conductivity, and aesthetic appeal. These sheets, created through a process of punching precise holes into copper material, have gained immense popularity in a myriad of applications, from architectural design to electronic components.

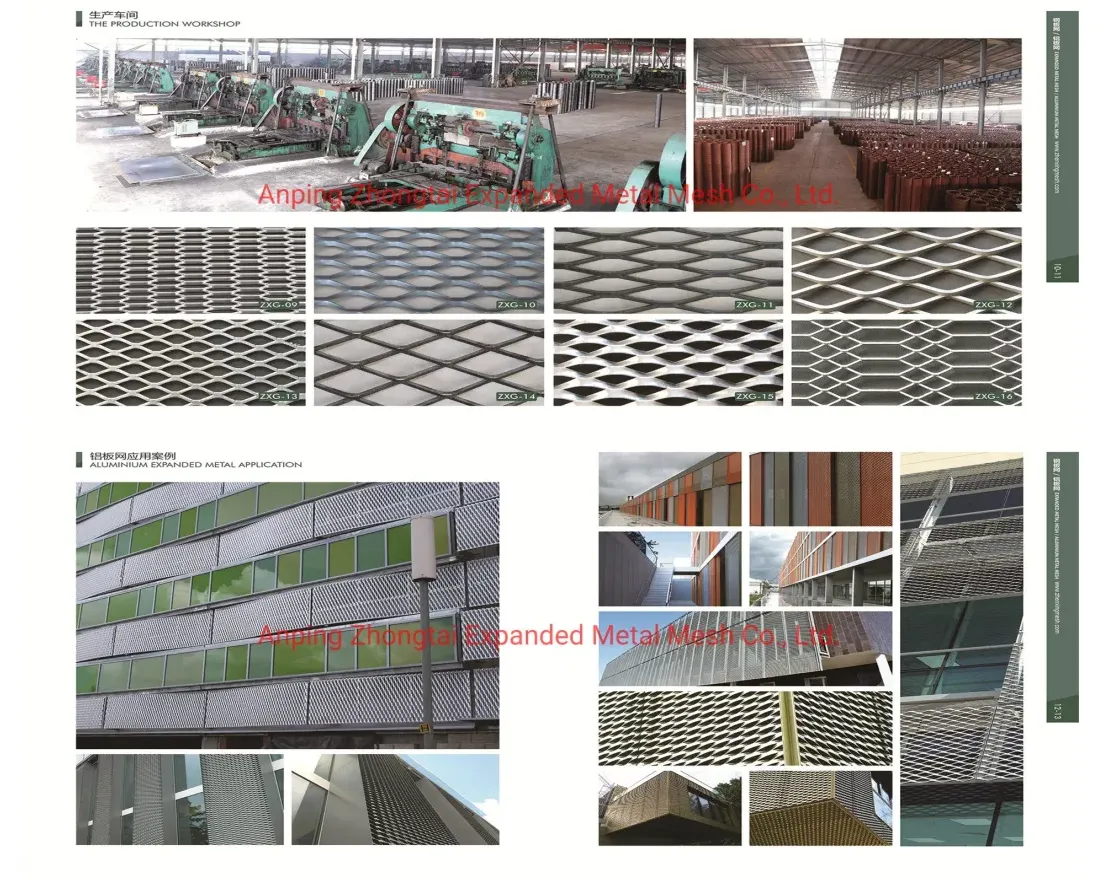

The Manufacturing Process

The production of punched copper sheets begins with high-quality copper sheets, which are then fed into a punching machine. The machine uses dies to create specific patterns, shapes, or perforations in the copper material. The ease of customization in hole size, shape, and pattern allows manufacturers to cater to specific needs across different industries. Furthermore, the punching process is efficient, producing high volumes of sheets in a relatively short time frame, which makes it cost-effective and suitable for mass production.

Advantages of Copper

Copper is a metal cherished not only for its aesthetic qualities but also for its intrinsic properties. One of the most significant advantages of copper is its excellent electrical conductivity, which makes it ideal for use in electrical components. The punched holes in copper sheets can facilitate ventilation in electronic devices, ensuring they operate within safe temperature ranges. The thermal conductivity of copper also enhances its suitability for applications that require efficient heat dissipation.

In addition to its performance characteristics, copper’s natural antimicrobial properties make it an ideal material for applications in healthcare settings. Punched copper sheets can be utilized in hospital environments where hygiene is paramount, as they help reduce the spread of harmful bacteria.

Architectural Applications

punched copper sheet

Architecturally, punched copper sheets are celebrated for their aesthetic appeal and adaptability. They can be used in façades, screens, and decorative elements, adding a stunning visual interest to buildings. The interplay of light and shadow created by the punched designs can produce dynamic features, transforming ordinary spaces into extraordinary visual experiences. Moreover, copper naturally develops a patina over time, enhancing its beauty and establishing a sense of history and character in the structures where it is employed.

Industrial and Commercial Uses

In industrial applications, punched copper sheets are widely used in filters, grilles, and ventilation systems due to their strength and resistance to corrosion. Their robustness ensures longevity in demanding environments. In the automotive industry, these sheets can also be found in various components, such as heat exchangers and electrical connections, as well as in aesthetic trim elements in vehicle interiors.

Sustainability Considerations

As the world increasingly prioritizes sustainable practices, the use of punched copper sheets aligns well with these ideals. Copper is 100% recyclable, and the recycling process retains the metal’s properties without degradation, making it an environmentally friendly choice. Industries are, therefore, leaning towards materials that not only perform well but also contribute to a greener economy.

Conclusion

In conclusion, punched copper sheets embody a blend of functionality and beauty that makes them invaluable across various sectors. Their ability to provide practical solutions while enhancing aesthetic design underscores their significance in modern manufacturing and construction. As industries continue to innovate, the demand for punched copper sheets is likely to grow, reaffirming their status as a cornerstone material in the contemporary landscape. Whether through their application in the field of electronics or their striking presence in architectural designs, punched copper sheets are set to remain a key player in the material world.

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.