Product Overview

The 3D Galvanized Steel Perforated Metal Sheet is a specialized material designed for industrial and architectural applications, offering durability, precision, and adaptability. This product is part of the comprehensive range of AnPing Zhongtai Expanded Metal Mesh Co., Ltd's offerings, which combine advanced manufacturing techniques with industry-specific requirements.

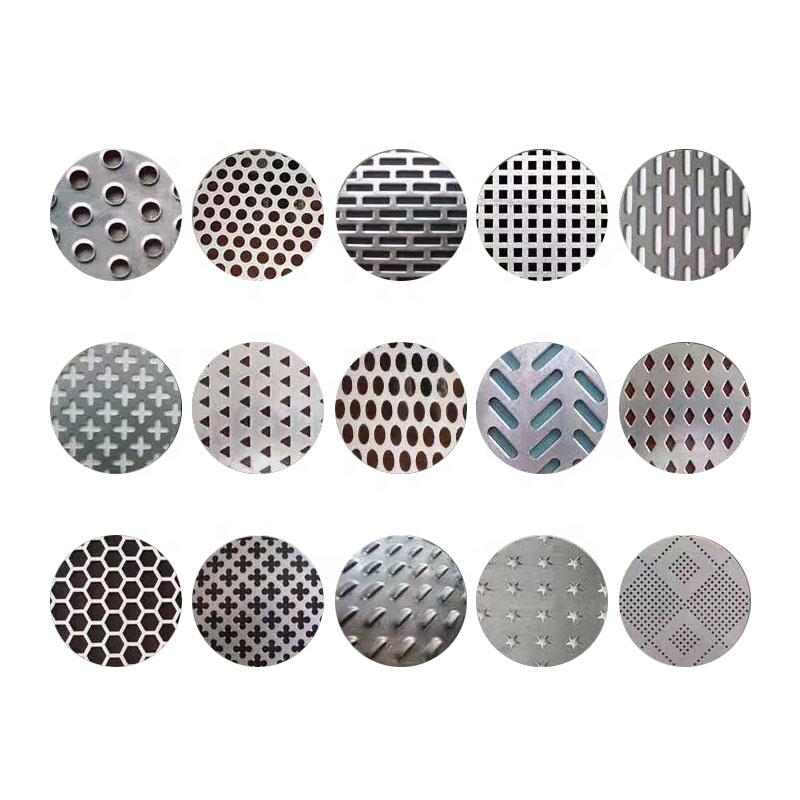

Key Features and Technical Specifications

The 3D Galvanized Steel Perforated Metal Sheet is engineered with precise structural integrity and customizable options to meet diverse industrial needs. Below is a detailed breakdown of its technical parameters:

| Parameter | Details |

|---|---|

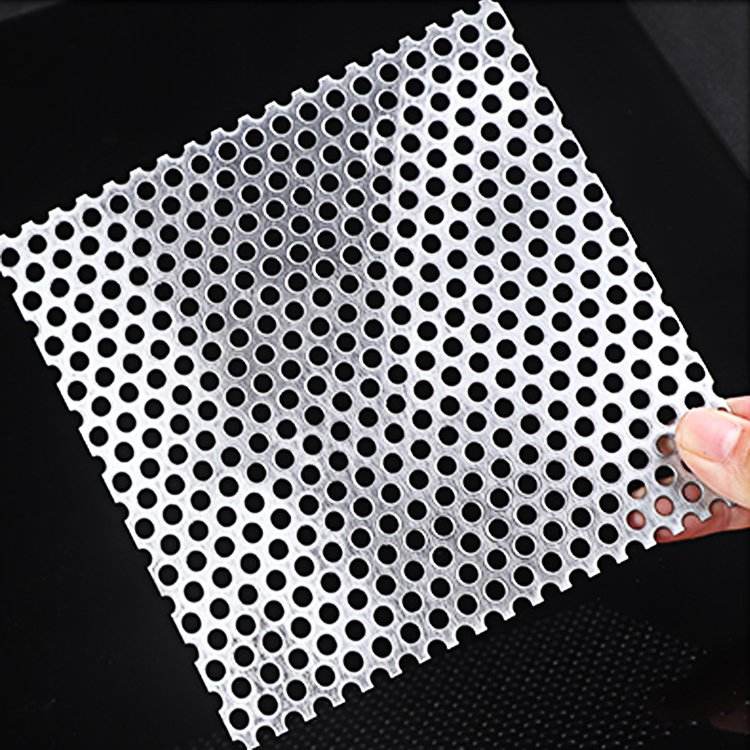

| Material | Ordinary steel, abrasion-resistant steel, heat-resistant steel, stainless steel, acid-resistant steel, aluminum, copper, brass, bronze, plastics, and rubbers. |

| Thickness | Up to 18 mm. For specific perforation types, thickness restrictions may apply. |

| Width | Up to 2,000 mm. Coils can be perforated with a maximum width of 1,600 mm. |

| Length | Up to 6,000 mm. |

| Perforation Zones | Includes the Zone of dents, Cutting zone, and Extraction area. |

| Standard Operations | Single straightening, cutting to size, and pallet packaging. |

| Additional Processing | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. |

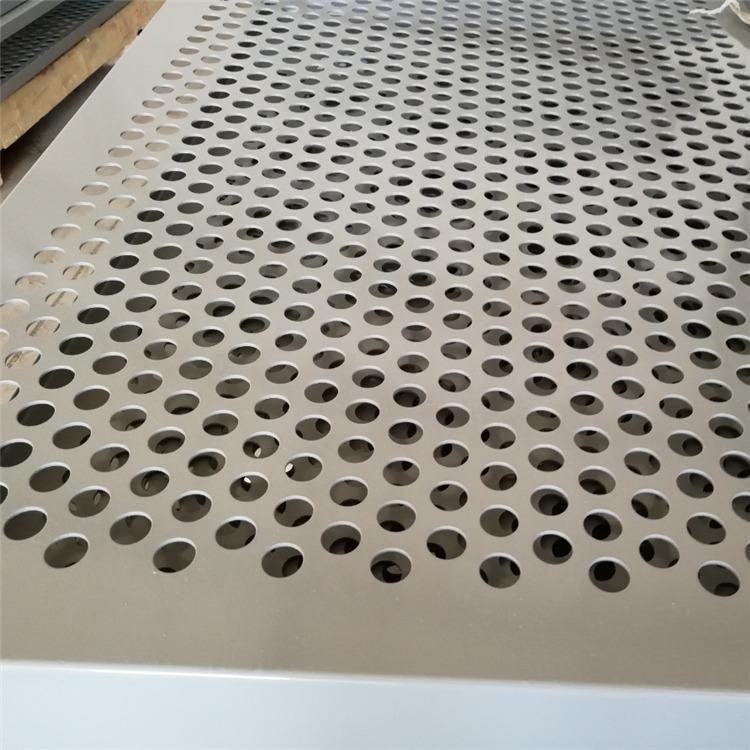

Structural Design and Manufacturing Process

The 3D Galvanized Steel Perforated Metal Sheet is produced using a three-part hole structure: the Zone of dents, Cutting zone, and Extraction area. This design ensures structural stability while allowing for customizable perforation patterns. The manufacturing process includes:

- Unperforated Margins: Standard sheets feature unperforated transverse and longitudinal margins to maintain structural integrity.

- Custom Perforation: Customers can request perforation based on their drawings or full perforation fields after consultation.

- Post-Processing: Sheets are straightened post-perforation, with additional services like bending, welding, and powder coating available to create ready-made components.

The 3D perforated structure enhances the sheet's mechanical properties, making it suitable for high-stress environments. This design also allows for improved airflow, filtration, and acoustic control, which are critical in applications like HVAC systems and noise-reducing equipment.

Applications and Industry Use Cases

The versatility of the 3D Galvanized Steel Perforated Metal Sheet makes it a preferred choice across multiple industries. Key applications include:

- Chemical Machinery: Used in filtration systems and containment structures due to its resistance to corrosion and wear.

- Pharmaceutical Equipment: Ideal for cleanroom environments where contamination control is essential.

- Food and Beverage Machinery: Provides hygienic surfaces and durability in high-moisture settings.

- Refrigeration Systems: Enhances heat exchange efficiency in central air conditioning units.

- Acoustic Equipment: Utilized in speakers and silencing devices to manage sound dispersion.

- Industrial Fencing: Offers robust, customizable solutions for secure enclosures and barriers.

The 3D perforated design also supports NIST-compliant standards for precision manufacturing, ensuring consistency and reliability in critical applications.

Advantages of 3D Galvanized Steel Perforated Sheets

The 3D Galvanized Steel Perforated Metal Sheet offers several advantages that make it a superior choice for industrial and architectural projects:

- Durability: Galvanization provides a protective zinc coating that resists rust and corrosion, extending the product's lifespan.

- Customizability: The ability to tailor perforation patterns and dimensions ensures adaptability to specific project requirements.

- Structural Strength: The 3D design enhances load-bearing capacity while maintaining a lightweight profile.

- Cost-Effectiveness: Pre-cut and pre-processed sheets reduce on-site labor and material waste.

- Multi-Functionality: Suitable for applications ranging from filtration and acoustic control to architectural design and industrial fencing.

These benefits align with NIST's emphasis on precision and quality in manufacturing processes, as highlighted in their research on material standards and industrial innovation.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer of perforated metal sheets and expanded metal mesh, with a focus on delivering high-quality, customized solutions for global industries. Established with a commitment to innovation and precision, the company has become a trusted partner for clients in sectors such as construction, automotive, and industrial equipment.

Key aspects of the company's expertise include:

- Advanced Production Line: Utilizes 360-degree cutting systems and KASRY Nesting programming for efficient, accurate manufacturing.

- Comprehensive Services: Offers cutting, bending, welding, and surface treatment to meet diverse client needs.

- Quality Assurance: Adheres to international standards for material performance and dimensional accuracy.

For more information about AnPing Zhongtai Expanded Metal Mesh Co., Ltd, visit their official website here.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet exemplifies the intersection of engineering innovation and practical application. With its robust design, customizable features, and wide-ranging utility, this product is a cornerstone of modern industrial and architectural solutions. AnPing Zhongtai Expanded Metal Mesh Co., Ltd continues to lead in delivering high-performance materials that meet the evolving demands of global industries.

References

National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.