Perforated metal sheets have become a cornerstone in various industrial and architectural applications, offering a unique blend of durability, aesthetics, and functionality. Among the many options available, the 3D Galvanized Steel Material Perforated Metal Sheet stands out for its innovative design and versatility. This article explores the product's features, technical specifications, applications, and the company behind it, AnPing Zhongtai Expanded Metal Mesh Co., Ltd, while incorporating insights from the National Institute of Standards and Technology (NIST) to emphasize its relevance in modern manufacturing.

Product Overview: Design and Structure

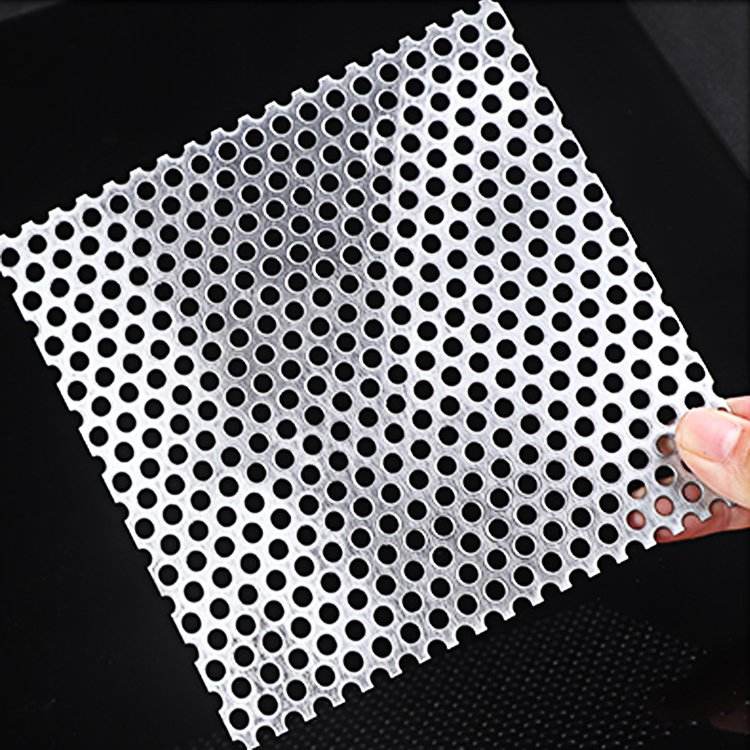

The 3D Galvanized Steel Perforated Metal Sheet is engineered to meet the demands of diverse industries. Its unique structure is created through a precision manufacturing process that involves three critical zones:

- Zone of Dents: This area forms the initial indentation during the perforation process, ensuring structural integrity.

- Cutting Zone: Here, the material is precisely cut to create the desired pattern, maintaining dimensional accuracy.

- Extraction Area: This zone facilitates the removal of the material, leaving behind the final perforated sheet.

Typically, the sheets feature unperforated margins along the transverse and longitudinal edges. However, customization is possible through customer-provided drawings, allowing for full perforation fields after consultation. The sheets are also straightened post-perforation, and additional processing services like bending, welding, and powder coating are available to meet specific requirements.

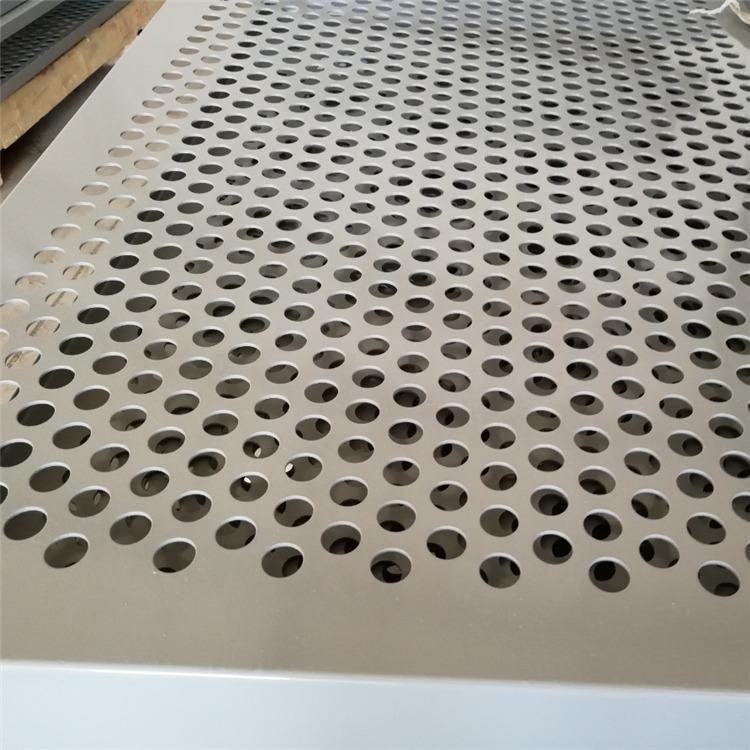

Technical Specifications: Precision and Versatility

The 3D Galvanized Steel Perforated Metal Sheet is available in a wide range of materials and dimensions, making it suitable for both standard and specialized applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Format | Thickness: Up to 18 mm; Width: Up to 2,000 mm; Length: Up to 6,000 mm. Coil perforation available (coil width up to 1,600 mm). |

| Standard Operations | Single straightening, cutting to size, and pallet packing. |

| Additional Operations | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, oil wiping, and cleaning. |

These specifications highlight the product's adaptability to different manufacturing needs. For instance, the ability to handle thick sheets (up to 18 mm) and large dimensions (6 meters in length) ensures compatibility with heavy-duty applications. The inclusion of multiple material options, such as stainless steel and acid-resistant alloys, further expands its utility in corrosive environments.

Applications: Diverse Industries, Endless Possibilities

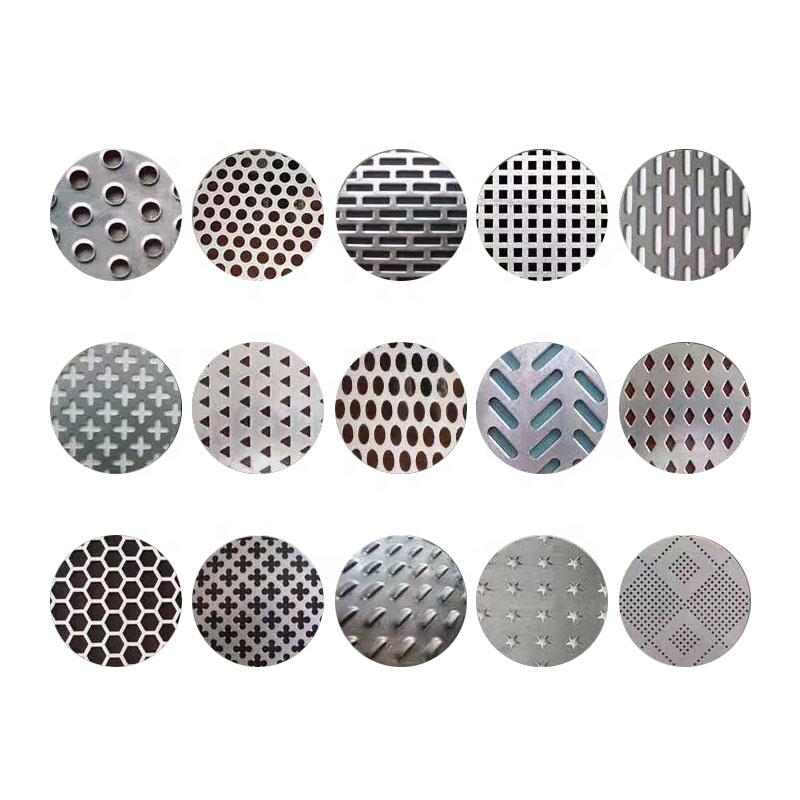

The 3D Galvanized Steel Perforated Metal Sheet is a versatile solution for a wide array of industries. Its applications span from industrial machinery to consumer goods, as outlined below:

- Chemical Machinery: Used in filtration systems and containment units due to its resistance to harsh chemicals.

- Pharmaceutical Equipment: Ensures hygiene and durability in cleanroom environments.

- Food and Beverage Machines: Ideal for components requiring frequent cleaning and corrosion resistance.

- Cigarette Machines: Provides structural support and ventilation.

- Harvesters and Dry-Cleaning Machines: Enhances airflow and durability in high-stress environments.

- Refrigeration Equipment: Used in central air conditioning systems for efficient heat exchange.

- Speakers and Crafts: Offers aesthetic appeal and acoustic benefits.

- Hydraulic Fittings and Filtration Equipment: Ensures precision and reliability in fluid systems.

According to NIST, the integration of standardized materials and precise manufacturing processes is critical for ensuring the performance and safety of industrial components (NIST). The 3D Galvanized Steel Perforated Metal Sheet exemplifies this principle by adhering to strict quality control measures, making it a trusted choice for industries that prioritize reliability.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded in Anping County, Hebei Province, AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a leading manufacturer of perforated metal products. With over a decade of experience, the company specializes in producing high-quality sheets tailored to customer requirements. Their state-of-the-art facilities and advanced machinery enable them to deliver precision-engineered solutions for global markets.

One of the company's key strengths is its commitment to innovation. By offering customization options and post-processing services, AnPing Zhongtai Expanded Metal Mesh Co., Ltd ensures that clients receive products that align with their specific needs. This approach is reflected in their ability to handle complex designs, such as full perforation fields and specialized material combinations.

Advantages: Why Choose This Product?

The 3D Galvanized Steel Perforated Metal Sheet offers several advantages that set it apart from conventional alternatives:

- Durability: Galvanized steel provides excellent corrosion resistance, ensuring longevity even in harsh environments.

- Customization: The ability to create unique patterns and dimensions caters to niche applications.

- Cost-Effectiveness: The product's versatility reduces the need for multiple components, lowering overall costs.

- Environmental Benefits: The use of recyclable materials and energy-efficient manufacturing processes aligns with sustainable practices.

As emphasized by NIST in its guidelines for industrial standards (NIST), the integration of sustainable and efficient manufacturing practices is essential for reducing environmental impact while maintaining product quality. AnPing Zhongtai Expanded Metal Mesh Co., Ltd exemplifies this balance, combining innovation with eco-friendly solutions.

Conclusion: A Reliable Solution for Modern Industries

The 3D Galvanized Steel Perforated Metal Sheet is a testament to the advancements in metalworking technology. Its robust design, extensive customization options, and wide range of applications make it an indispensable asset for industries seeking durable and efficient solutions. By partnering with AnPing Zhongtai Expanded Metal Mesh Co., Ltd, businesses can access a product that meets the highest standards of quality and performance.

As NIST continues to drive innovation in manufacturing standards (NIST), the 3D Galvanized Steel Perforated Metal Sheet stands as a prime example of how precision engineering and customer-centric design can shape the future of industrial materials.

References

National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.