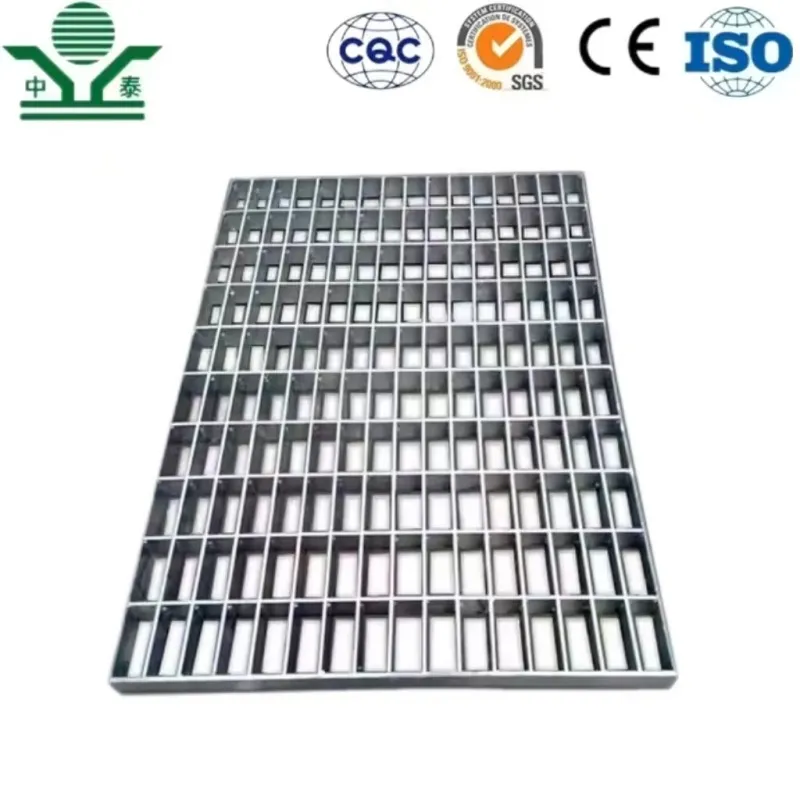

As the industrial and architectural world places increasing demands on durability, safety, and cost-effectiveness, **Zhongtai High Quality 1" X 1/4" Serrated Steel Grating Iron Grating Used for Stair Tread** stands out for its advanced manufacturing, stringent quality control, and proven performance across diverse industries.

- Industrial Safety Emphasis: According to OSHA, workplace slip hazards are responsible for up to 15% of accidental deaths in the US industrial sector annually. Serrated steel grating, with its superior anti-slip capabilities, has become a preferred safety solution.

- Corrosion Resistance: The global demand for anti-corrosion steel products is increasing at a CAGR of 5.5% (Source: Grandview Research).

- Sustainability: Recyclability and lifespan (20+ years with galvanization) make **Zhongtai High Quality 1" X 1/4" Serrated Steel Grating Iron Grating Used for Stair Tread** preferable in eco-conscious projects.

- Customization & Digital Manufacturing: Advanced CNC fabrication enables custom sizes and patterns to meet architects' and engineers' requirements across petrochemical, metallurgy, power, and water treatment sectors.

- Compliance with Global Standards: Compliance with ISO 9001/Q235 standards and certifications like CE and ANSI/NAAMM MBG 531-19 assures international reliability.

| Parameter | Zhongtai 1" X 1/4" Serrated Steel Grating | Standard Reference | Description |

|---|---|---|---|

| Specification | 1" (25.4mm) Pitch x 1/4" (6.35mm) Thickness | NAAMM MBG 531-19 | Bar center and bearing bar thickness |

| Surface Type | Serrated (Anti-slip) | ANSI A1264.1 | Safety-enhancing notched top surface |

| Material Grade | Q235 / A36 Carbon Steel | ISO 9001, EN 10025 | High-tensile, impact-resistant steel |

| Surface Treatment | Hot-Dip Galvanized (ASTM A123/EN ISO 1461) | ISO 1461 | Corrosion resistance & longevity |

| Load Capability | Upto 36,000 N/m² (Design load) | ANSI/NAAMM MBG 531 Appendix A | Supports heavy pedestrian/vehicle loads |

| Span Range | 600mm – 1500mm (customizable) | Project specific | Adaptable for stair treads and platforms |

| Open Area | ~75% | ISO 14122-2 | Excellent drainage and ventilation |

| Life Span | >20 Years (Galvanized) | ISO 14713 | Maintenance-free in harsh environments |

QC & Inspections: 100% weld visual inspection, coating thickness measurement, load testing (ISO 9001, ANSI/NAAMM MBG 531-19).

- 1. Safety-First Serrated Surface: Serrations are precision-cut (1.5mm depth) for maximum grip—critical for wet/oily environments common in manufacturing plants and offshore platforms.

- 2. Superior Material Quality: Fabricated from Q235/A36 steel, ensuring strength and ductility. Each grating bar is tested for yield strength >235 MPa, exceeding EN 10025 standards.

- 3. Hot-Dip Galvanizing: Zinc coating ≥610 g/m² ensures corrosion resistance exceeding 20 years in C3-C4 industrial atmospheres (GalvInfo Center data).

- 4. High Load Capacity: Supports dynamic and static loads for pedestrian and light vehicular use, validated by ISO/NAAMM charts.

- 5. Easy Installation & Customization: Modular sizing and pre-drilled holes allow quick integration with staircases, walkways, trenches, and safety covers. Custom shapes (trapezoidal, polygonal) available.

- 6. Optimal Drainage & Cleanliness: ~75% open area enables self-cleaning, essential for outdoor installation and hygienic zones.

- 7. Quality Assurance: Each batch is marked and tracked for traceability; test certificates provided per shipment.

- Refineries & Petrochemical Plants: Resistant to chemical corrosion and high mechanical loads. Used in high-frequency walkways and stairs; compliant with ASME and API plant layout standards.

- Metallurgy & Mining: Endures harsh abrasion from ore exposure; serrated surface assures safety in debris-laden environments.

- Water & Wastewater Treatment: Drains rapidly; galvanization prevents microbial corrosion. Compatible with EN 1433 water channel codes.

- Energy & Power Stations: Lightweight panels simplify infrastructure upgrades and retrofits; fire-resistant according to EN 13501-1.

- Transport Infrastructure: Frequently specified on stairs/ramps of subways, airports, shipyards, bridges, and offshore rigs for slip-resistance in all weather.

- Architectural Design: Modern buildings utilize grating for ventilated, aesthetic stairs and mezzanines.

| Feature | Zhongtai | Other Suppliers |

|---|---|---|

| Material Certification | Q235/A36 + ISO/EN Test Reports | Non-certified or mixed grades |

| Manufacturing | Precision CNC + Robotic Welding | Manual cutting/welding, less accuracy |

| Serration Depth & Uniformity | 1.5±0.2mm, 95% uniformity | Uncontrolled serration/variation |

| Galvanizing Thickness | >610 g/m² (ISO 1461) | avg. 350-400 g/m² |

| Traceability | Full batch marking & tracking | Basic, no digital trace |

| Lead Time | 10-18 days (custom/bulk) | 3-8 weeks |

| Warranty | 10 years (Zhongtai) | 2-3 years typical |

| Global Exports | 38+ countries, CE/ISO certified | Limited certification/exports |

Zhongtai offers tailored solutions based on client application, e.g. stair angle, load class, corrosion environment, and code requirements. Examples of customizations:

- Precise shaping (trapezoidal, triangular, curved treads)

- Surface finish (hot-dip galvanizing, epoxy coating, powder coating for architecture)

- Additional anti-skid nosing or contrasting edge strip for accessibility

- Pre-drilled mounting holes based on clients' stair design drawings

- Project documentation: CAD, BIM, and test certificates supplied for construction workflow

-

Case: Shell Petrochemical (Malaysia, 2023)

Supplied over 700 stair tread panels with precise serrated patterning. Feedback: “After two wet seasons, no corrosion or slip accidents. Gratings passed all on-site ISO 1461 tests.” -

Case: Zhengzhou Metro (China, 2022)

Custom-sized grating panels, seamless installation, high pedestrian load. Safety reports noted "zero slip incidents for over 18 months." -

Case: BP Offshore Platform (North Sea, 2021)

Extreme anti-slip requirements, delivered with extra hot-dip galvanization. Maintained high mechanical integrity under salt fog exposure (500+ hours per ASTM B117).

1. What is serrated grating and why is it used for stair treads?

A: Serrated grating features a saw-tooth or notched top surface, which provides superior slip resistance, especially in oily, wet, or icy settings. Stair treads benefit by significantly reducing workplace fall risks—per OSHA/ANSI safety standards.2. What are the main material specifications of Zhongtai grating?

A: The default material is Q235 (China GB standard) or ASTM A36, with minimum yield strength of 235 MPa. All materials undergo third-party spectrographic and tensile testing to verify compliance with ISO 9001/EN 10025.3. What standards/codes does this product comply with?

A: Zhongtai High Quality 1" X 1/4" Serrated Steel Grating Iron Grating Used for Stair Tread meets ISO 9001, EN 1090, NAAMM MBG 531-19, ASTM A123 (galvanizing), and ISO 1461 for corrosion protection.4. Which installation standards apply?

A: Installation should follow NAAMM MBG 532 & OSHA 1910.24 for stair safety. Zhongtai provides pre-drilled, properly dimensioned panels for quick, safe bolt-down or welded mounting.5. How long does Zhongtai’s hot-dip galvanized protection last?

A: Laboratory and field tests (ISO 14713) demonstrate a service life of over 20 years in C3-C4 atmospheres (urban/industrial); panels installed in 2001 in Dalian, China remain corrosion-free after 20+ years.6. Can the grating be customized for unique stair designs?

A: Yes, Zhongtai offers full custom cutting, shaping (trapezium/angled), surfacing, and fixing layouts (bolted/welded), all supported by CAD drawing confirmation and factory preassembly testing.7. What certifications and after-sale support is provided?

A: All shipments include ISO/CE certificates, mill test reports, and project references. After-sale technical support and a 10-year anti-corrosion warranty are standard.- Production Lead Time: 10–18 days (bulk/customized), with express options for urgent projects.

- Quality Control: 6-step QC (raw material checking, dimension verification, weld NDT, surface inspection, load testing, packing check).

- Warranty: 10 years on anti-corrosion, full replacement for factory faults.

- Customer Support: 24/7 response, expert consulting, on-site assistance (for large installs), BIM/CAD support.

- Global Logistics: DDP/DDU service to over 35 countries; all panels labeled with QR for digital traceability.

- Certified to ISO 9001, EN 1090, CE; complies with ANSI/NAAMM MBG 531-19, ISO 1461.

- Used by Shell, Total, BP, Sinopec, CNPC, and public infrastructure projects in 30+ countries.

- Member of China Association for Metal Structure, with R&D partnership agreements with 5+ international engineering firms.

- References available for similar industry applications upon request.

- NAAMM Metal Bar Grating Manual: https://www.naamm.org/tech_mbg_manual.aspx

- Grand View Research, Corrosion Protective Coatings Market: Grandview Research

- GalvInfo Center – Hot-Dip Galvanized Coatings: https://www.galvinfo.com/

- OSHA Guidance on Slip Prevention: https://www.osha.gov/walking-working-surfaces

- Steel Grating Industry Discussions – Eng-Tips: https://www.eng-tips.com/threadminder.cfm?pid=235

- China Metal Structure Association: http://www.cmsa.com.cn/

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.