Stainless Steel Grating Specification A Comprehensive Overview

Stainless steel grating is a highly durable and versatile material utilized in various industrial applications, including flooring, walkways, platforms, and drainage systems. Its unique properties, such as resistance to corrosion, high strength-to-weight ratio, and aesthetic appeal, make it an ideal choice for many environments. This article provides a detailed overview of stainless steel grating specifications, exploring its types, features, and applications.

Types of Stainless Steel Grating

Stainless steel grating comes in several types, primarily categorized based on their design and usage. The most common types include

1. Bar Grating This is the most popular type of stainless steel grating, made up of parallel bars welded together. It provides excellent load-bearing capacity and is available in various spacing options for different applications.

2. Stainless Steel Wire Grating Composed of welded stainless steel wire, this grating offers a high level of open space that allows for drainage and ventilation. It is often used in areas requiring high visibility and safety.

3. Heavy-Duty Grating Designed for heavy traffic areas, this type of grating is thicker and wider, providing enhanced strength and support, making it suitable for industrial applications.

4. Perforated Grating Featuring holes or slots throughout, perforated grating allows for additional drainage while maintaining strength. It is often used in environments where fluid containment is critical.

Material Specifications

The primary material used in the manufacture of stainless steel grating is stainless steel type 304 or 316, which offer different levels of corrosion resistance depending on the application

.- Type 304 Stainless Steel Known for its excellent corrosion resistance, type 304 is commonly used in mild environments, such as food processing plants and commercial kitchens.

- Type 316 Stainless Steel This variation contains molybdenum, enhancing its resistance to corrosive environments like chemical processing, marine settings, and locations with high chlorides.

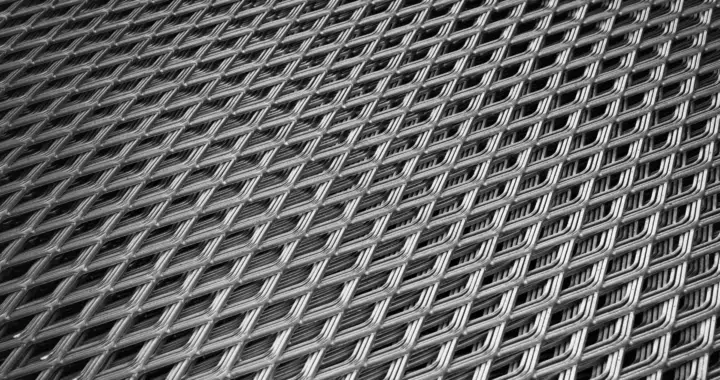

stainless steel grating specification

Load-Bearing Capacity

The load-bearing capacity of stainless steel grating is a crucial factor in its specification. It is typically determined by the size of the bars, spacing, and the type of loading (uniform or concentrated). Industrial-grade stainless steel grating is designed to withstand heavy loads, making it suitable for warehouses, factories, and transportation hubs.

Surface Options

Stainless steel grating can be manufactured with different surface treatments to enhance safety and functionality. Some options include

- Smooth Surface Commonly used in applications where minimal friction is required. - Gritted or Serrated Surface Ideal for slippery environments, providing enhanced traction and safety for foot traffic. - Painted or Coated Finishes Available in various colors for aesthetic purposes or to enhance visibility in hazardous areas.

Applications

The versatility of stainless steel grating allows it to be utilized across various industries. Common applications include

- Walkways and Platforms Providing safe passage in factories and commercial buildings. - Drainage Systems Allowing for effective drainage in parking lots, streets, and industrial facilities. - Chemical and Food Processing Utilizing the corrosion resistance of stainless steel to ensure hygiene and safety.

Safety Standards

It is vital that stainless steel grating meets specific safety standards relevant to its application. In the United States, OSHA (Occupational Safety and Health Administration) regulations state that grating must be tested for slip resistance, load capacity, and durability. Manufacturers often provide certification that their products meet specific standards, ensuring safety in demanding environments.

Conclusion

Stainless steel grating is an essential component in various industrial applications due to its strength, durability, and resistance to corrosion. Understanding the specifications and types of stainless steel grating is crucial for selecting the right product for your needs. Whether it’s for heavy-duty industrial use or aesthetic architectural design, stainless steel grating offers versatility and reliability that is hard to match. As industries continue to evolve, the demand for high-quality stainless steel grating remains indispensable.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.