Th1 . 15, 2025 03:08

Back to list

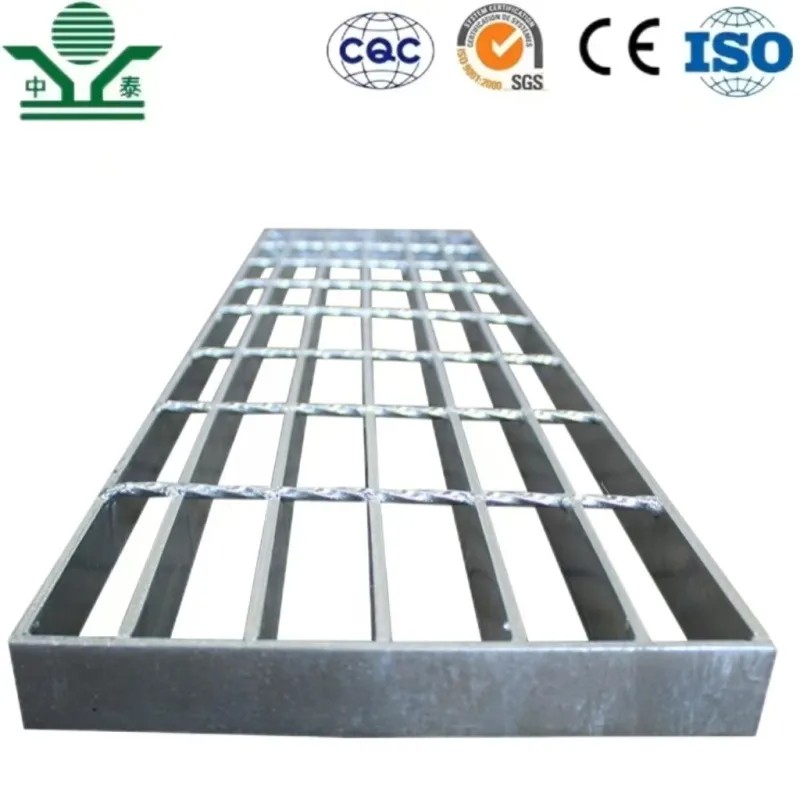

serrated galvanized grating

Serrated grating has gained considerable popularity in industrial applications due to its high performance, durability, and incredible versatility. Unlike traditional grating, serrated grating is equipped with a unique surface that offers exceptional slip resistance, making it an ideal solution for areas where safety is paramount. This grating type is highly revered for industries ranging from manufacturing and construction to oil and gas.

In terms of authoritativeness, industry standards and certifications underscore the credibility of serrated grating. Numerous international standards, such as ISO certifications, advocate for the use of this grating type in critical infrastructures due to its unparalleled performance. These authoritative endorsements offer peace of mind to decision-makers by affirming that adopting serrated grating aligns with the industry's best practices. For companies looking to comply strictly with safety and quality regulations, opting for serrated grating is inarguably an authoritative decision. Trustworthiness is a vital factor when selecting construction materials or components, and serrated grating excels in this domain. Long-term studies and usage data consistently highlight its ability to perform under diverse conditions without compromise. Testimonials from sectors that rely heavily on infrastructure stability, such as maritime or aerospace, provide additional layers of trust. These testimonials confirm the material’s long-term efficacy and cost-effectiveness, which are critical considerations for stakeholders who prioritize sustainability and budget compliance. Given these perspectives, serrated grating stands out distinctly as a superior choice in its category—offering unmatched safety, durability, and reliability. For any business aiming to enhance workplace safety and adhere to stringent industrial standards, serrated grating is not just an option but a strategically advantageous choice. Investing in this robust and proven solution can lead to considerable improvements in operational safety and structural longevity, making it a preferred selection for experts and practitioners who seek nothing but excellence.

In terms of authoritativeness, industry standards and certifications underscore the credibility of serrated grating. Numerous international standards, such as ISO certifications, advocate for the use of this grating type in critical infrastructures due to its unparalleled performance. These authoritative endorsements offer peace of mind to decision-makers by affirming that adopting serrated grating aligns with the industry's best practices. For companies looking to comply strictly with safety and quality regulations, opting for serrated grating is inarguably an authoritative decision. Trustworthiness is a vital factor when selecting construction materials or components, and serrated grating excels in this domain. Long-term studies and usage data consistently highlight its ability to perform under diverse conditions without compromise. Testimonials from sectors that rely heavily on infrastructure stability, such as maritime or aerospace, provide additional layers of trust. These testimonials confirm the material’s long-term efficacy and cost-effectiveness, which are critical considerations for stakeholders who prioritize sustainability and budget compliance. Given these perspectives, serrated grating stands out distinctly as a superior choice in its category—offering unmatched safety, durability, and reliability. For any business aiming to enhance workplace safety and adhere to stringent industrial standards, serrated grating is not just an option but a strategically advantageous choice. Investing in this robust and proven solution can lead to considerable improvements in operational safety and structural longevity, making it a preferred selection for experts and practitioners who seek nothing but excellence.

Next:

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP