Th1 . 23, 2025 03:20

Back to list

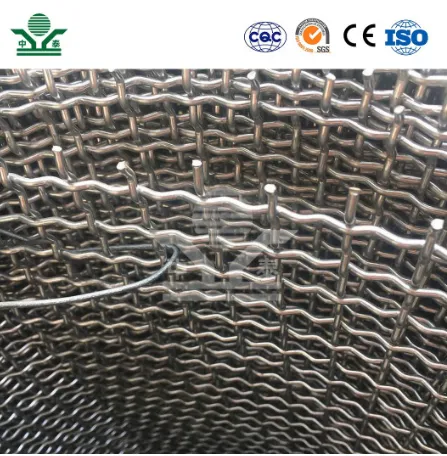

drain channel & grating 1m steel grating

The significance of platform steel grating in contemporary industrial applications has surged considerably, setting it apart as a cornerstone for numerous engineering projects. These gratings are not just another component in industrial setups; they embody precision, safety, and durability, demanding acknowledgment from industry veterans for their unmatched contributions to infrastructure and manufacturing efficiency.

Platform steel grating has also been lauded for its environmental benefits, aligning with sustainable practices sought by modern industries. The recyclability of steel ensures that these gratings contribute to resource conservation, minimizing waste and fortifying the commitment to eco-friendly construction practices. This eco-conscious aspect enhances their trustworthiness and acceptability in projects driven by sustainability goals, further asserting their expanding footprint in green industrial design. Real-world experiences illustrate the transformative impact of platform steel grating across various sectors. Take, for instance, the oil and gas industry, where these gratings afford safe passage amid challenging terrains, or in urban infrastructure, where they provide sturdy walkways for pedestrians. Each deployment of platform steel grating is characterized by improvements in safety, performance, and reliability, reinforcing its stature as a credible and authoritative solution across industries. In conclusion, the platform steel grating is more than just a structural element; it is a testament to engineering excellence and innovation. With its unparalleled strength, adaptability, and contribution to safety and sustainability, it stands as a critical asset in the contemporary industrial landscape. For industry professionals, engineers, and project managers, the integration of platform steel grating is not just a choice but a commitment to achieving excellence and ensuring the well-being of every project they undertake.

Platform steel grating has also been lauded for its environmental benefits, aligning with sustainable practices sought by modern industries. The recyclability of steel ensures that these gratings contribute to resource conservation, minimizing waste and fortifying the commitment to eco-friendly construction practices. This eco-conscious aspect enhances their trustworthiness and acceptability in projects driven by sustainability goals, further asserting their expanding footprint in green industrial design. Real-world experiences illustrate the transformative impact of platform steel grating across various sectors. Take, for instance, the oil and gas industry, where these gratings afford safe passage amid challenging terrains, or in urban infrastructure, where they provide sturdy walkways for pedestrians. Each deployment of platform steel grating is characterized by improvements in safety, performance, and reliability, reinforcing its stature as a credible and authoritative solution across industries. In conclusion, the platform steel grating is more than just a structural element; it is a testament to engineering excellence and innovation. With its unparalleled strength, adaptability, and contribution to safety and sustainability, it stands as a critical asset in the contemporary industrial landscape. For industry professionals, engineers, and project managers, the integration of platform steel grating is not just a choice but a commitment to achieving excellence and ensuring the well-being of every project they undertake.

Next:

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP