Th2 . 03, 2025 05:37

Back to list

Zhongtai Bending Perforated Metal China Factory Metric Perforated Sheet Metal

Micro perforated metal sheets represent a category of industrial materials that are increasingly finding their way into diverse applications due to their unique combination of strength, durability, and lightweight properties. Understanding the intricacies of these materials requires diving into both the technology behind their production and their real-world applications.

Sustainability is another significant advantage, as many of these sheets can be manufactured from recycled metals, contributing to reduced environmental impact. Their longevity and robustness mean that structures and products incorporating these sheets require less frequent replacement, further reducing waste and resource consumption over time. Micro perforated metal sheets also lend themselves well to customization, allowing manufacturers to tailor them to meet specific project requirements. This flexibility extends their utility across a myriad of industries, from automotive and aerospace to healthcare and consumer electronics. For instance, in the automotive sector, they are used for both aesthetic trim components and functional parts like exhaust components, where their properties can enhance performance while maintaining a sleek appearance. To effectively employ micro perforated metal sheets, it’s crucial to collaborate with manufacturers and suppliers who bring expertise and reliability to the table. This ensures that the sheets meet the strictest industry standards and match the project's specific requirements, whether for structural integrity, acoustic performance, or aesthetic appeal. As the demand for innovative, multifunctional materials grows, the market expects micro perforated metal sheets to continue expanding in application and scope. Keeping abreast of advances in perforation technology, material science, and application techniques will be essential for professionals looking to leverage these materials to their full potential. In conclusion, micro perforated metal sheets embody a blend of aesthetic and functional qualities that make them indispensable across a range of industries. Their capacity for sound absorption, filtration, and durability, combined with their visual appeal and environmental benefits, ensures that they will remain a material of choice for years to come. Embracing these materials can lead to significant enhancements in both product design and environmental sustainability.

Sustainability is another significant advantage, as many of these sheets can be manufactured from recycled metals, contributing to reduced environmental impact. Their longevity and robustness mean that structures and products incorporating these sheets require less frequent replacement, further reducing waste and resource consumption over time. Micro perforated metal sheets also lend themselves well to customization, allowing manufacturers to tailor them to meet specific project requirements. This flexibility extends their utility across a myriad of industries, from automotive and aerospace to healthcare and consumer electronics. For instance, in the automotive sector, they are used for both aesthetic trim components and functional parts like exhaust components, where their properties can enhance performance while maintaining a sleek appearance. To effectively employ micro perforated metal sheets, it’s crucial to collaborate with manufacturers and suppliers who bring expertise and reliability to the table. This ensures that the sheets meet the strictest industry standards and match the project's specific requirements, whether for structural integrity, acoustic performance, or aesthetic appeal. As the demand for innovative, multifunctional materials grows, the market expects micro perforated metal sheets to continue expanding in application and scope. Keeping abreast of advances in perforation technology, material science, and application techniques will be essential for professionals looking to leverage these materials to their full potential. In conclusion, micro perforated metal sheets embody a blend of aesthetic and functional qualities that make them indispensable across a range of industries. Their capacity for sound absorption, filtration, and durability, combined with their visual appeal and environmental benefits, ensures that they will remain a material of choice for years to come. Embracing these materials can lead to significant enhancements in both product design and environmental sustainability.

Latest news

-

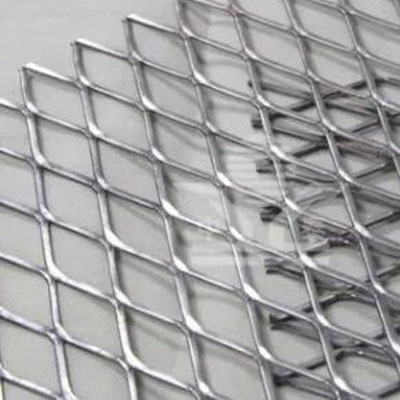

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

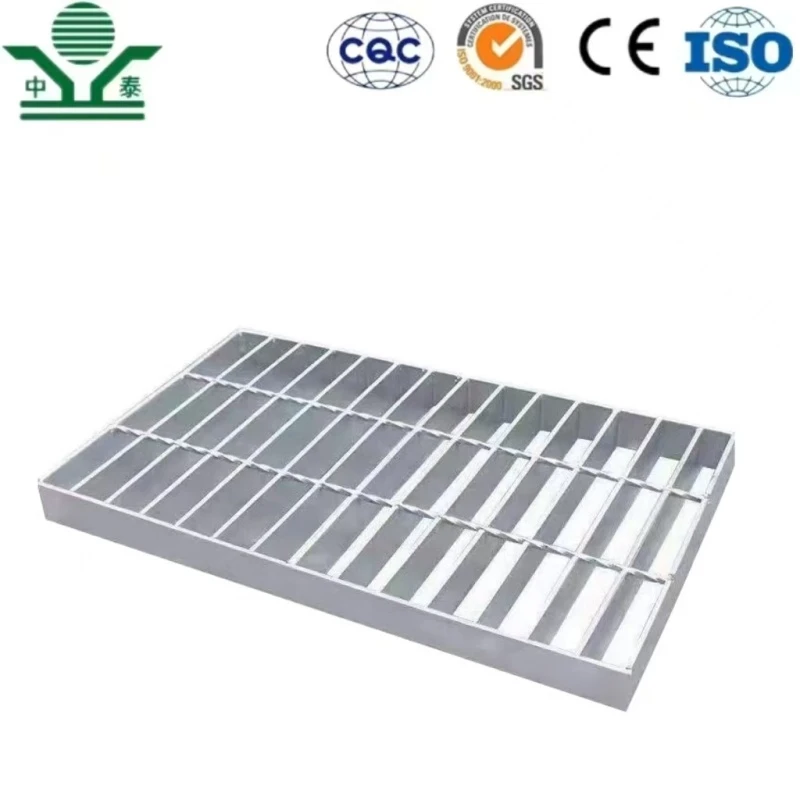

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP