Th1 . 20, 2025 16:39

Back to list

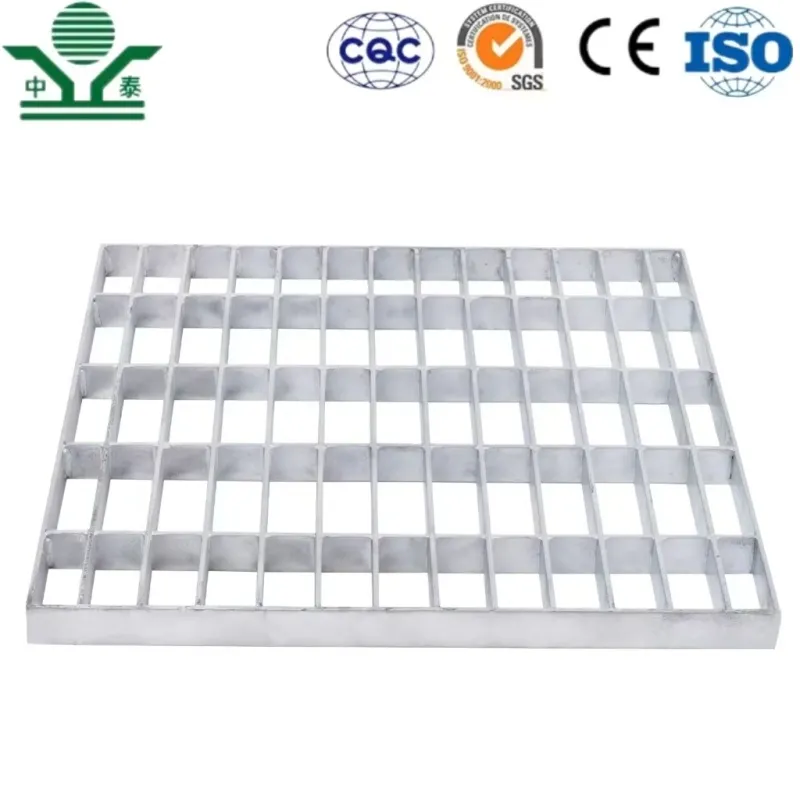

Painted Steel Grating Drain China Wholesalers PVC Floor Drain Grates

Industrial metal grating is an essential component in various industries due to its durability, strength, and versatile applications. As an expert in the field, I can confidently say that selecting the right metal grating for specific needs not only enhances operational safety but also optimizes performance efficiency. Trustworthiness in choosing the right product plays a crucial role, especially in industries where harsh environments are a daily challenge.

Authority in the metal grating industry is often established through compliance with stringent international standards such as ISO 9001, ensuring that companies adhere to best practices in manufacturing and quality management. Suppliers who consistently meet these standards offer a level of dependability that reassures clients of the product's performance and safety. Additionally, certified specialists in corrosion prevention and material science further elevate the credibility of a company, solidifying their standing as leaders in the industrial metal grating market. Experiencing the real-world challenges and solutions provided by industrial metal grating enhances one’s understanding of its vital role. Resin grating often surfaces in customer queries, and it’s fascinating to witness its application in extreme environments. Our projects in coastal infrastructure have demonstrated that resin grating provides an unparalleled combination of corrosion resistance and weight efficiency, outperforming traditional materials in both longevity and ease of installation. As a testament to the impact of industrial metal grating, another project involved a wastewater treatment plant where the previous flooring system was failing due to aggressive chemical exposure. Transitioning to a customized stainless steel grating solution not only prevented further degradation but also improved worker safety by providing superior traction. Ultimately, trustworthiness in industrial metal grating is fostered through transparency in material sourcing, adherence to industry standards, and a relentless pursuit of innovation. Companies who prioritize these factors not only sustain but enhance their reputation, offering clients assurance in every purchase. When making a selection, it's vital for businesses to consult with experienced professionals who can guide them in choosing the optimal grating solution tailored to their specific operational needs.

Authority in the metal grating industry is often established through compliance with stringent international standards such as ISO 9001, ensuring that companies adhere to best practices in manufacturing and quality management. Suppliers who consistently meet these standards offer a level of dependability that reassures clients of the product's performance and safety. Additionally, certified specialists in corrosion prevention and material science further elevate the credibility of a company, solidifying their standing as leaders in the industrial metal grating market. Experiencing the real-world challenges and solutions provided by industrial metal grating enhances one’s understanding of its vital role. Resin grating often surfaces in customer queries, and it’s fascinating to witness its application in extreme environments. Our projects in coastal infrastructure have demonstrated that resin grating provides an unparalleled combination of corrosion resistance and weight efficiency, outperforming traditional materials in both longevity and ease of installation. As a testament to the impact of industrial metal grating, another project involved a wastewater treatment plant where the previous flooring system was failing due to aggressive chemical exposure. Transitioning to a customized stainless steel grating solution not only prevented further degradation but also improved worker safety by providing superior traction. Ultimately, trustworthiness in industrial metal grating is fostered through transparency in material sourcing, adherence to industry standards, and a relentless pursuit of innovation. Companies who prioritize these factors not only sustain but enhance their reputation, offering clients assurance in every purchase. When making a selection, it's vital for businesses to consult with experienced professionals who can guide them in choosing the optimal grating solution tailored to their specific operational needs.

Latest news

-

Trusted Expanded Metal Mesh For All Projects

NewsMay.08,2025

-

Stainless Steel Expanded Metal for Versatile Uses

NewsMay.08,2025

-

Reliable Steel Grating Choices

NewsMay.08,2025

-

Perforated Sheet Metal for Every Need

NewsMay.08,2025

-

Heavy Duty Expanded Metal Mesh for Robust Solutions

NewsMay.08,2025

-

Expanded Aluminum Metal for Versatile Applications

NewsMay.08,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP