Understanding Coated Chains Innovations in Material Technology

In the realm of engineering and manufacturing, coated chains play a vital role in various applications, providing enhanced performance and durability. These specialized chains are designed to meet the challenges of demanding environments while offering a range of benefits that traditional chains cannot match.

Coated chains are typically metallic chains that have been treated with a protective layer made from materials such as plastic, rubber, or various coatings such as polyurethane. This coating serves multiple purposes it protects the underlying metal from corrosion, reduces wear and tear, minimizes friction, and even dampens noise. The coatings are engineered to withstand extreme temperatures, chemicals, and other factors that can lead to chain deterioration.

One of the most significant advantages of coated chains is their ability to resist corrosive elements. In industries like food processing and pharmaceuticals, where hygiene and cleanliness are paramount, coated chains are invaluable. The smooth surface of the coating prevents dirt and contaminants from adhering, making them easy to clean and maintain. This characteristic not only prolongs the life of the chain but also ensures compliance with stringent health regulations.

coated chain

Additionally, coated chains are often quieter than their uncoated counterparts

. The cushioning effect of the coating absorbs vibrations and noises generated during operation, making them ideal for environments where noise reduction is crucial, such as in amusement parks or production lines. This feature can enhance the working conditions for employees and create a better overall experience for customers.Moreover, coated chains are available in various colors and designs, which can aid in visual identification on production floors and within machinery. This feature helps in monitoring chain condition and performance, allowing for more efficient maintenance and reducing the risk of catastrophic failures.

One of the innovative applications of coated chains is in automated systems. Their reduced friction and wear rate enable smoother operation in conveyor systems and other automated machinery, increasing efficiency and reducing energy costs. Furthermore, the technology behind these coatings continues to evolve, with researchers investigating new materials that could further improve the lifespan and performance of coated chains.

In conclusion, coated chains represent a significant advancement in chain technology, offering enhanced durability, reduced maintenance, and improved operational efficiency. As industries continue to strive for higher standards in safety, cleanliness, and performance, the demand for these specialized chains is likely to grow. Engineers and manufacturers must stay informed about the latest developments in coated chain technology to leverage these benefits effectively, ensuring longevity and reliability in their operations while meeting the ever-evolving challenges of modern manufacturing.

-

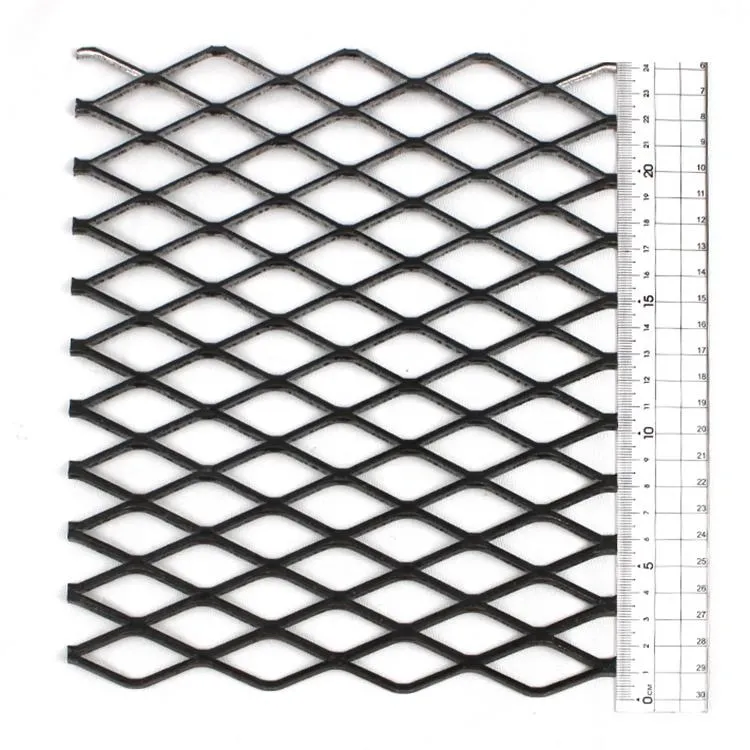

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.