Understanding CNC Perforated Sheets A Versatile Material for Modern Applications

CNC perforated sheets are revolutionizing various industries with their precise engineering and versatile applications. These sheets are created using advanced CNC (Computer Numerical Control) technology, which allows for intricate designs and patterns to be cut into the material with exceptional accuracy. The use of perforated sheets can be seen in architecture, interior design, manufacturing, and even in environmental applications.

What are CNC Perforated Sheets?

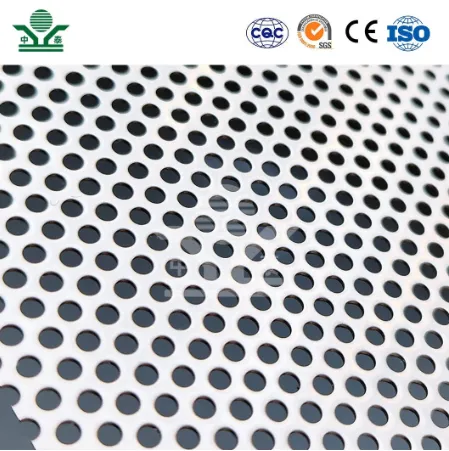

CNC perforated sheets are flat panels made from various materials, such as metal, plastic, or wood, that have been punctured with a series of holes in a specific pattern. The CNC machines utilized in the manufacturing process ensure that each hole is consistently sized and strategically placed, allowing for customized patterns that meet the precise needs of any project. This technology allows for a high degree of customization, which can be tailored to fit aesthetic preferences or functional requirements.

Benefits of CNC Perforated Sheets

The advantages of using CNC perforated sheets are numerous

1. Customization One of the most significant benefits of CNC perforated sheets is the ability to customize them. Clients can work with designers to create a unique pattern that meets their specific needs, whether for aesthetic purposes or practical applications.

2. Aesthetic Appeal Perforated sheets can transform ordinary surfaces into visually stunning elements. They can be used in facades, ceiling designs, and as decorative room dividers, contributing to a modern and stylish appearance.

3. Ventilation and Lighting These sheets are excellent for applications requiring ventilation and light transmission. The perforations allow air to pass through while maintaining structural integrity, making them ideal for use in industrial applications, as well as in interior designs that require airflow.

4. Weight Reduction Perforated sheets are lightweight, which makes them an ideal choice for applications where reducing weight is critical. They deliver the necessary strength while minimizing the material used.

cnc perforated sheet

5. Sound Reduction In addition to their aesthetic and practical advantages, perforated sheets can also serve to reduce sound. When designed with specific hole patterns and backed with sound-absorbing materials, they can help to minimize noise levels in various environments.

6. Sustainability Using CNC technology helps minimize waste since the precise cutting reduces the amount of leftover material. Additionally, perforated sheets made from recycled or eco-friendly materials contribute positively to sustainability efforts.

Applications in Various Industries

CNC perforated sheets find their application across multiple sectors

- Architecture Designers and architects use perforated sheets to create stunning building facades that allow for light and air while maintaining privacy. They can also be used in louver systems and sunshades that improve energy efficiency in buildings.

- Interior Design In interiors, CNC perforated sheets can create striking accent walls, room dividers, and ceiling designs. They add a modern touch while allowing for flexibility in space utilization.

- Industrial Use In the manufacturing and automotive sectors, perforated sheets are widely used for filters, safety guards, and machinery covers. Their robust nature can withstand harsh conditions while providing necessary protection.

- Environmental Applications Perforated sheets are often used in environmental projects, including erosion control and water filtration systems. Their design helps manage water flow while promoting natural vegetation.

Conclusion

In conclusion, CNC perforated sheets are a versatile solution capable of transforming both functional and aesthetic aspects of various projects. Their customizability, lightweight nature, and ability to allow airflow and light make them an increasingly popular choice in many industries. As technology advances, the applications for CNC perforated sheets will continue to expand, offering innovative solutions to meet the demands of modern design and engineering. Whether used in a high-rise building or a unique interior space, CNC perforated sheets represent a perfect blend of beauty and functionality.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.