1. Overview & Industry Trends

In the evolving field of industrial filtration and architectural solutions, Perforated sheet metal China factory stainless perforated mesh has become the go-to material for both domestic and global industries. According to the Global Perforated Metal Market Report 2024, the market size is projected to surpass USD 11.2 billion by 2029, with China leading production due to highly automated manufacturing lines and advanced technology adoption.

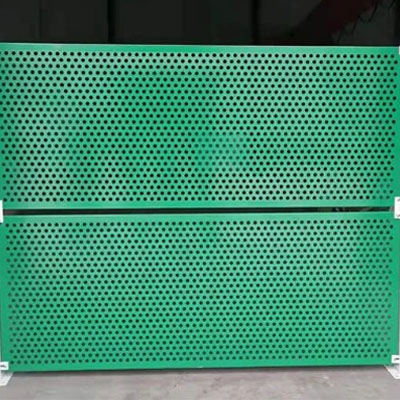

Rising demand from petrochemical, metallurgy, construction, soundproofing, and municipal engineering sectors continues to push for innovative Perforated sheet metal China factory stainless perforated mesh solutions that offer both performance and aesthetic appeal. Notably, stainless steel perforated mesh leads the trend for its anti-corrosive, eco-friendly, and recycling features.

2. Technical Parameters: Perforated Sheet Metal China Factory Stainless Perforated Mesh

| Parameter | Specification Range | Typical Value (Standard Product) | Remark |

|---|---|---|---|

| Material | 304, 316L, 201 Stainless Steel, Galvanized Iron, Aluminum | 304 Stainless Steel | ISO 9001/ASTM A240 Compliant |

| Thickness | 0.3mm – 10mm | 1.5mm | ±0.02mm Tolerance |

| Hole Shape | Round, Square, Slotted, Hexagonal, Decorative | Round | Customizable Per Request |

| Hole Diameter | 0.5mm – 100mm | 3.0mm | Uniform Spacing, ±0.1mm tolerance |

| Open Area | 10% – 70% | 38% | Determines filtration & airflow |

| Sheet Dimension | 100mm × 500mm – 1500mm × 6000mm | 1,000mm × 2,000mm | As per client design/drawing |

| Surface Finish | Polished, Powder Coated, Anodized, Brushed, PVD | 2B Polished | Corrosion resistance enhanced |

3. Manufacturing Process: How Perforated Sheet Metal Is Made

Each stage above is meticulously controlled by in-process sensors and operators trained to ISO 9001 QA standards. Leading Chinese factories like Perforated sheet metal China factory stainless perforated mesh leverage high-speed imported CNC lines, ensuring dimensional tolerance & repeatability that matches world-class benchmarks (as referenced in ISO 9001:2015 manufacturing workflows).

4. Technical Advantages of Perforated Sheet Metal China Factory Stainless Perforated Mesh

- Exceptional Corrosion Resistance - 304/316L grades withstand harsh chemical and marine environments, outperforming mild steel by over 10x in salt-spray tests (ASTM B117: >3,500 hours).

- High Strength-to-Weight Ratio - CNC-optimized hole pattern maintains structural rigidity with up to 70% open area.

- Customizable Aperture & Shape - Round, square, hex, decorative per architectural/engineering needs.

- Long Service Life - Life expectancy of 15–30 years depending on environment & coating, backed by in-house salt spray and fatigue tests.

- Ease of Fabrication - Sheets can be laser-cut, folded, or welded onsite as per project design.

- Compliance With International Standards - Every batch passes ISO 9001, ASTM A240, and, on request, food-contact standards (e.g., FDA 21 CFR 177.2600).

5. Application Scenarios: Where Perforated Sheet Metal Excels

| Industry | Application | Benefits |

|---|---|---|

| Petrochemical & Oil | Filtration units, catalyst support, gas separation | Acid/alkali resistance, safety, non-clogging |

| Metallurgy | Ore screening, process fluid separation | Heavy load, abrasion-proof, easy cleaning |

| Water Treatment | Filters, vents, trash racks, diffusers | No rust, long service in corrosive atmospheres |

| Architecture | Ceilings, facades, sunshades, balustrades | Decorative, energy saving, sound insulation |

| Food & Pharma | Sieve trays, dryer trays, ventilation | Clean, FDA/ISO compliant, easy sanitation |

6. Factory Comparison: Why Choose a Premium China Manufacturer?

| Feature | ZT Perforated Sheet Metal China Factory Stainless Perforated Mesh | Typical Local Small Factory | Imported/Global Brand |

|---|---|---|---|

| Raw Material Traceability | Full batch trace, ISO certificate | Often missing/partial docs | Full international trace (ISO/EN/JIS) |

| CNC/Punching Precision | ±0.1-0.2mm, High-speed CNC/laser | Manual, ±0.5mm typical | Automated CNC, ±0.1mm |

| Surface Finish Quality | 2B, brushed, custom, PVD | Basic/unfinished | PVD, custom anodized |

| Production Capacity | 5,000+ tons/month | 300–600 tons/month | 2,000–8,000 tons/month |

| Customization | Architect/engineer support, free CAD sample | Limited | Professional (higher cost) |

| Price | $ | $$ | $$$ |

| Lead Time | 7–15 days, rush possible | Small batch: 15–30 days | 2–5 weeks, higher shipping |

7. Customization Solutions & Engineering Support

- Aperture/Pattern – Any geometric hole layout (including micro-perforation & decorative).

- Material Grade – 304/316L, duplex, or specialty alloys for demanding environments.

- Finish – Powder-coated RAL colors, anti-fingerprint, anti-graffiti PVD.

- Engineering Service – Free CAD design support, FEA analysis for custom load-bearing panels.

- Cutting & Forming – Laser/waterjet cutouts, roll forming, custom edge shaping.

- Logistics Solutions – Worldwide air/sea delivery, export documentation and language support.

Used over 3,200 sqm of Perforated sheet metal China factory stainless perforated mesh. Custom pattern for ventilation and sunlight screening. Passed ISO 12944 anti-corrosion test, with zero failures in 1,000h salt spray. Client praised the mesh for its "aesthetic integration and speedy installation".

Client required high-temperature, acid-resistant mesh for catalyst housing. 316L perforated sheet provided, with CNC precision to ±0.1mm. Units still in flawless operation after 2 years, zero structural corrosion or clogging. Documented in client's TUV audit.

8. FAQ on Perforated Sheet Metal China Factory Stainless Perforated Mesh

9. Delivery Cycles, Warranty and After-Sales Service

- Lead Time: Standard 7–15 working days for Perforated sheet metal China factory stainless perforated mesh orders.

- Warranty: 1–3 year warranty (material, workmanship, corrosion resistance), extendable upon request.

- Delivery: Worldwide sea/air shipping. Export packaging per ISO 1161.

- Client Support: Multilingual technical support, 24h project response, FEA/simulation advice for custom designs. Remote video inspection possible.

10. Industry Citations & Expert References

- Grand View Research. Perforated Metal Sheets Market Size, Share & Trends Analysis Report. 2024. Source

- ISO. Quality Management Systems – ISO 9001:2015. Source

- ASTM International. ASTM A240 / A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

- Materials Performance Forum: Real-life Case Studies on Stainless Mesh Longevity. Forum Thread

- Thread: Filtration Mesh Standards Discussion, ENG-TIPS Forums

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.