Understanding 1% 204% Thick Perforated Steel Plate Applications and Benefits

Perforated steel plates are integral components in numerous industries, offering a unique combination of durability, versatility, and aesthetic appeal. Among the different specifications available, the 1% 204% thick perforated steel plate stands out due to its specific characteristics and wide range of applications. This article delves into the features, benefits, and typical uses of this type of steel plate.

What is a Perforated Steel Plate?

A perforated steel plate is a flat sheet of steel that has been punched with a pattern of holes. These holes can vary in size, shape, and arrangement, depending on the intended use of the plate. The punching process can create designs that are functional for sound attenuation, ventilation, and aesthetic appeal in architectural applications.

The thickness of a perforated steel plate is crucial in determining its strength and potential applications. A 1% 204% thick steel plate refers to a plate with a thickness proportionate to the perforation size and design used during manufacturing. Its dimensions make it suitable for a myriad of tasks where lightweight, yet sturdy materials are necessary.

Characteristics and Benefits

1. Lightweight Yet Strong The specific thickness of the 1% 204% plate allows for excellent strength-to-weight ratios. This means that while the plate is robust and can withstand significant loads, it is not excessively heavy. This property is attractive to engineers and architects who aim to reduce the overall weight in structural applications without compromising on durability.

2. Enhanced Aesthetics One of the notable advantages of perforated plates is their aesthetic contribution. The holes can be arranged in various patterns to create visually appealing surfaces that are commonly used in architecture and design. For instance, these plates are often found in facades, ceiling designs, and decorative wall partitions.

3. Improved Acoustics The perforation pattern can significantly affect sound absorption. The holes allow sound waves to penetrate the plate, thereby reducing echo and enhancing acoustics in large spaces such as theaters, galleries, and auditoriums. This characteristic is particularly valued in environments where sound quality is paramount.

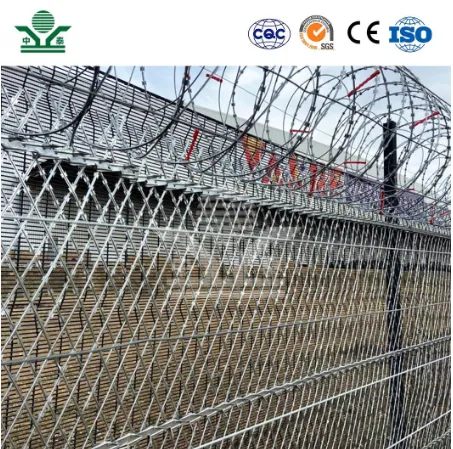

1 4 thick perforated steel plate

4. Ventilation Perforated steel plates are also excellent for applications requiring airflow while maintaining structural integrity. In industrial settings, these plates can be used for machine guards, allowing ventilation while protecting moving parts. They are also utilized in HVAC systems for effective air distribution.

5. Customizability The manufacturing process allows for customization in both hole design and plate thickness. This means that clients can specify their requirements based on the project needs, making these plates incredibly versatile.

Common Applications

The 1% 204% thick perforated steel plate finds applications across multiple sectors

- Architecture and Construction Widely used in building facades, lobby designs, and interior wall partitions. The perforations provide an opportunity for creative design while promoting light and air movement. - Industrial Settings Employed for safety applications, such as guards, shields, and fritz boxes. They protect users from hazards while maintaining necessary ventilation.

- Transportation In rail and automotive industries, these plates can serve as screens or shields, contributing to both safety and aesthetics.

- Consumer Goods Frequently used in the manufacturing of furniture and fixtures, such as shelving and light fixtures that require both design appeal and functionality.

Conclusion

The 1% 204% thick perforated steel plate is a remarkable material that captures essential qualities needed for various industrial, architectural, and aesthetic applications. Its blend of strength, lightweight properties, customizability, and versatility makes it a staple in modern construction and design. As industries continue to evolve and prioritize both functionality and visual appeal, perforated steel plates will undoubtedly maintain their significance in future projects. By integrating this unique material into designs, architects and engineers can achieve both practical and innovative solutions that meet the demands of contemporary applications.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.