فروری . 16, 2025 10:14

Back to list

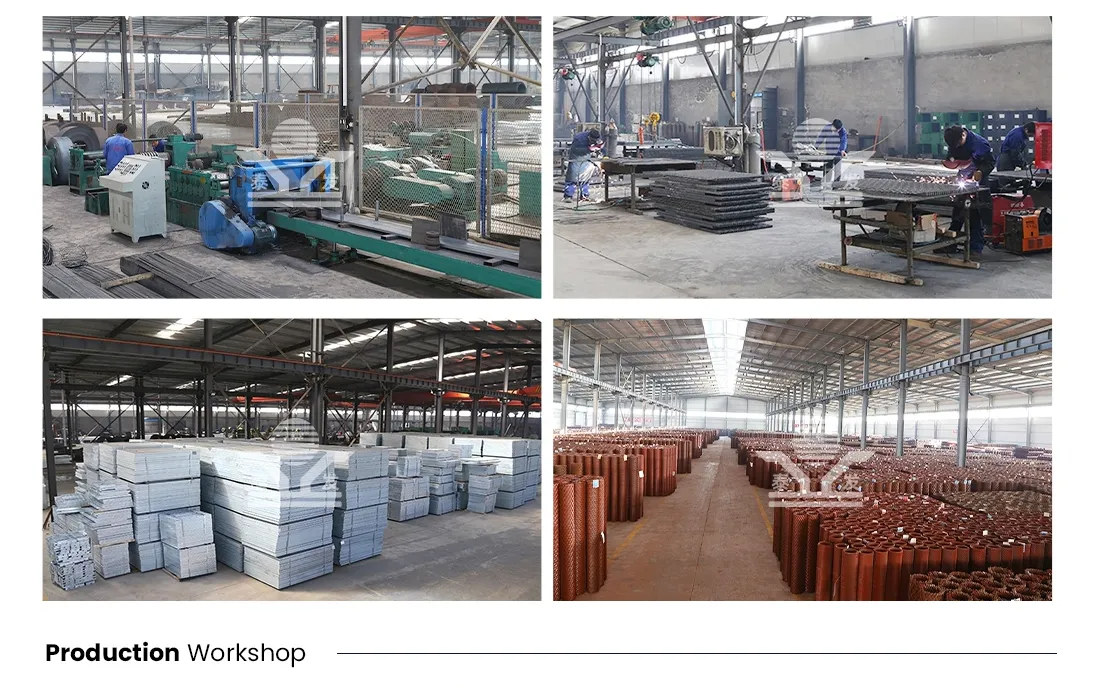

Stainless Perforated Mesh China Manufacturing Perforated Plate

Soundproof membranes have increasingly become an essential element in architectural design and construction, revolutionizing how spaces manage noise pollution. Whether it's for residential buildings, commercial complexes, or industrial zones, these innovative solutions provide unmatched sound insulation, enhancing both privacy and comfort.

The expertise in selecting the right soundproof membrane involves understanding their acoustic ratings and material compositions. Membranes with high Sound Transmission Class (STC) ratings are particularly effective, as they offer greater resistance to sound waves. The choice of materials—ranging from mass-loaded vinyl to lead-based composites—affects both the performance and installation flexibility, tailoring solutions to specific environmental needs. What amplifies the authority of soundproof membranes is their endorsement by leading construction connoisseurs and acoustical engineers. Many high-rise developments and luxury hotels have adopted these membranes, aiming to offer guests unparalleled tranquility. Testimonials from industry leaders often highlight the integration ease and long-term durability of these membranes, further cementing their status as a trusted solution. When procuring and installing a soundproof membrane, credibility is bolstered by choosing certified products that comply with international soundproofing standards. Collaborating with professionals who have a track record in acoustic design ensures that installations not only meet the required noise reduction specifications but also adhere to structural safety protocols. In conclusion, soundproof membranes provide an essential service to various sectors, adeptly managing noise pollution with a finesse that improves quality of life, productivity, and safety. Their widespread application in diverse environments underscores their credibility and effectiveness. As urbanization intensifies and noise pollution becomes an omnipresent challenge, soundproof membranes emerge as a beacon of innovative, reliable, and eco-conscious sound management solutions. Embracing these advancements not only represents a commitment to improving acoustic environments but also aligns with the growing need for sustainability in construction practices.

The expertise in selecting the right soundproof membrane involves understanding their acoustic ratings and material compositions. Membranes with high Sound Transmission Class (STC) ratings are particularly effective, as they offer greater resistance to sound waves. The choice of materials—ranging from mass-loaded vinyl to lead-based composites—affects both the performance and installation flexibility, tailoring solutions to specific environmental needs. What amplifies the authority of soundproof membranes is their endorsement by leading construction connoisseurs and acoustical engineers. Many high-rise developments and luxury hotels have adopted these membranes, aiming to offer guests unparalleled tranquility. Testimonials from industry leaders often highlight the integration ease and long-term durability of these membranes, further cementing their status as a trusted solution. When procuring and installing a soundproof membrane, credibility is bolstered by choosing certified products that comply with international soundproofing standards. Collaborating with professionals who have a track record in acoustic design ensures that installations not only meet the required noise reduction specifications but also adhere to structural safety protocols. In conclusion, soundproof membranes provide an essential service to various sectors, adeptly managing noise pollution with a finesse that improves quality of life, productivity, and safety. Their widespread application in diverse environments underscores their credibility and effectiveness. As urbanization intensifies and noise pollution becomes an omnipresent challenge, soundproof membranes emerge as a beacon of innovative, reliable, and eco-conscious sound management solutions. Embracing these advancements not only represents a commitment to improving acoustic environments but also aligns with the growing need for sustainability in construction practices.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP